Discover how stack racks can maximize storage space, improve organization, and enhance efficiency in various industries.

Read More

What is a transport rack?

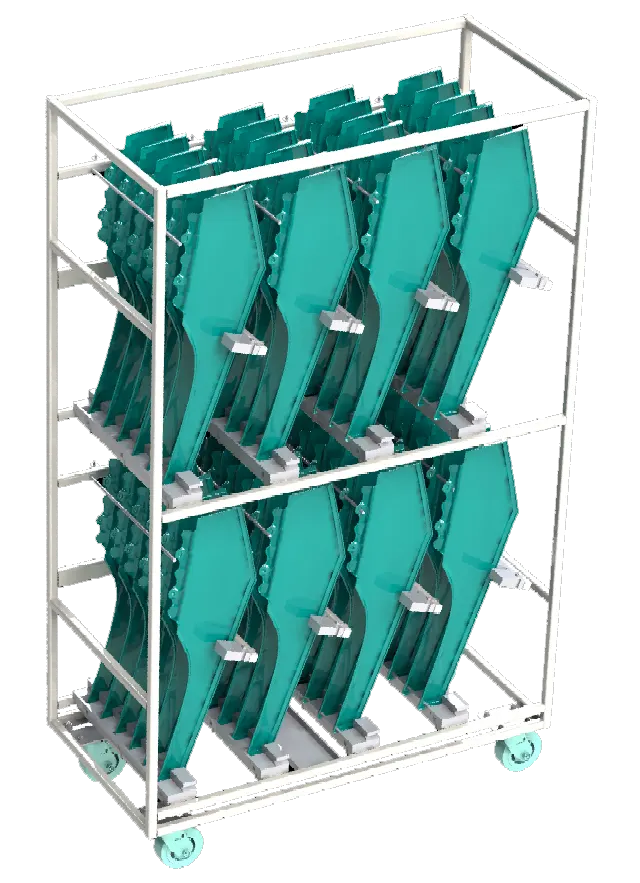

A transport rack is a specialized storage and transportation solution designed to securely hold and transport various types of goods. It offers a secure and efficient way to move objects within a facility or during transit. Transport racks are often made of robust materials like steel or aluminum, and they are built to handle large loads and frequent transportation.

Transport racks exist in a number of sizes and designs to support a wide range of commodities, including automobile components, electronics, furniture, and industrial equipment. They are commonly used in industrial facilities, warehouses, distribution centres, and logistics activities. Transport racks provide several major benefits, including increased storage capacity, protection against damage, improved handling and transportation efficiency, and workplace safety.

Uses and Benefits of Transport Racks

Transport racks are widely used across industries for their numerous advantages. Here are some specific uses and benefits of using transport racks:

-

Maximizing Storage Space: The design functions of transport racks are to optimize vertical and horizontal space utilization, allowing businesses to store and transport more goods in a given area. Ultimately, this helps in maximizing warehouse efficiency and reducing storage costs.

-

Protecting Goods: These racks are designed with protective features such as robust frames, dividers, and padding to protect goods from damage during transportation. In fact, they can effectively secure items and prevent shifting or collision during transit, minimizing the risk of breakage or loss.

-

Improving Efficiency: Using transport racks speeds up the loading and unloading process, reducing handling time and enhancing overall operational efficiency. Also, utilizing standard rack sizes make it easier to stack and organize goods, enabling quick access and retrieval.

-

Enhancing Workplace Safety: Equipping transport racks with safety features like load restraints, corner protection, and anti-tipping mechanisms helps ensure the secure transportation of goods. By maintaining proper load balance and stability, they minimize the risk of accidents and injuries in the workplace.

-

Facilitating Inventory Control: Transport racks improve inventory management by offering clear visibility and control over the number and location of items. Also, recording and identifying each rack can allow for simple inventory audits and accurate stock predictions.

-

Simplifying Material Handling: With the use of transport racks, manual handling of goods is minimized, reducing the physical strain on workers. As a result, this leads to less workplace injuries and an increase in employee safety.

Overall, transport racks offer significant benefits in terms of space optimization, protection, efficiency, safety, and inventory management.

Types of Transport Racks

There are many different styles of transport racks; each is made to fulfill particular needs depending on the type of items being transported and the method of transportation. Here are some common types of transport racks:

-

Wire Mesh Racks: Wire mesh racks are adaptable and lightweight, making them ideal for a variety of applications. They offer excellent visibility and ventilation, making them perfect for retaining delicate items and anything that require easy access.

-

Solid-sided Racks: Solid-sided racks offer enhanced protection and security for goods that require additional shielding from dust, debris, and unauthorized access. They are commonly used in industries such as electronics, pharmaceuticals, and high-value goods.

-

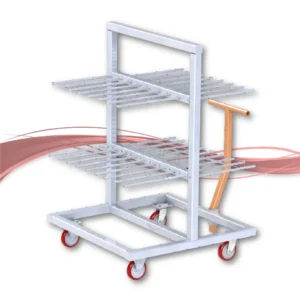

Rolling Racks: Rolling racks, also known as mobile racks, are equipped with casters or wheels that enable for easy movement across a facility. They are useful in situations where objects must be transported frequently or where capacity must be flexible.

-

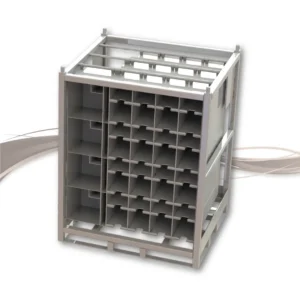

Collapsible Racks: The design purpose of collapsible racks is to be easily assembled and disassembled, allowing for space-saving storage when not in use. They are particularly beneficial for companies with limited storage space or those that require the flexibility to transport empty racks efficiently.

-

Pallet Racks: Pallet racks are designed to accommodate pallets and are commonly used in warehouses and distribution centers. They provide a sturdy and efficient storage solution, enabling easy access to goods with the use of forklifts or pallet jacks.

Each type of transport rack has its own set of advantages and is suited for specific applications. Choosing the right type depends on factors such as the nature of the goods, the transportation method, and the storage environment.

How to Choose the Right Transport Rack

When selecting a transport rack, it is essential to consider several factors to ensure it meets your requirements. Here are some key considerations to keep in mind:

-

Type of Goods: Identify which items you will be transporting and their specific requirements. Consider the dimensions, weight, fragility, and any particular handling or storage requirements.

-

Storage Space: Evaluate the available storage space and determine the dimensions and weight capacities that your transport racks should adhere to. Essentially, you want to optimize space utilization by ensuring that the racks fit within the storage areas.

-

Transportation Method: Think about the handling and transportation of the items during the journey. In essence, you want to select transport racks that provide the greatest amount of stability and protection for long distance travel.

-

Durability and Quality: Assess the durability and quality of the transport rack materials. Look for racks made from strong and reliable materials such as steel or aluminum, as they offer better resistance to wear and tear and ensure the longevity of the racks.

-

Customization Options:Rack manufacturers offer customization options such as adjustable dividers, removable shelves, or additional safety features to meet unique requirements.

-

Cost and Return on Investment: Consider the upfront cost of the transport racks and weigh it against the benefits and long-term value they provide. Look at the overall return on investment in terms of improved efficiency, reduced damage or loss, and extended rack lifespan.

By carefully considering these factors, you can choose the right transport rack that aligns with your specific requirements and offers optimal performance and durability.

Factors to Consider When Using a Transport Rack

Using a transport rack effectively involves taking certain factors into account to ensure the safe and efficient movement of goods. Here are some factors to consider when using a transport rack:

-

Load Capacity: Always adhere to the load capacity specified for your transport rack. In fact, overloading the rack can lead to instability, damage, or accidents. Distribute the weight evenly across the rack and never exceed the weight limit.

-

Loading and Unloading: To protect the items from damage and to ensure worker safety, load and unload items correctly. Use appropriate lifting equipment, secure the load properly, and ensure the center of gravity is well-balanced.

-

Stacking Height: Be mindful of the maximum stacking height limit for the transport rack. Ultimately, stacking above the height limit will compromise stability and create a hazardous situation.

-

Storage Environment: Take into account the storage environment and any specific requirements of the goods. Consider factors like temperature, humidity, ventilation, and protection from dust or moisture. Essentially, you want to choose the appropriate type of transport rack that can accommodate the specific storage conditions.

-

Regular Inspection: Inspect your transport racks on a regular basis for indicators of wear and damage. Inspect for bent frames, loose fasteners, and broken components. Repair or replace any damaged parts right away to guarantee sustained safety and performance.

By considering these factors and implementing proper procedures, you can maintain the integrity of your transport rack and ensure the safe and efficient handling of goods.

How to Properly Load and Unload a Transport Rack

Properly loading and unloading goods on a transport rack is crucial for maintaining their safety and integrity during transportation. Here are some steps to follow for a successful loading and unloading process:

-

Inspect the Rack: Before loading goods onto the transport rack, inspect it for any signs of damage or wear. Ensure that the rack is in good working condition and can handle the intended load.

-

Secure the Load: Use appropriate restraints such as straps, ropes, or chains to secure the load onto the transport rack. To keep stability, make sure the load is appropriately centered and balanced. Avoid over-tightening the restraints, as this can lead to unnecessary pressure on the goods.

-

Stabilize the Load: Verify the load’s stability after it is on the transport rack. To maintain a balanced weight distribution and center of gravity, adjust the load as necessary. Use additional padding or dividers if required to prevent items from colliding or rubbing against each other during transit.

-

Unload with Caution: Use the same procedure as for loading to unload the items from the transport rack. Before attempting to lift or move the goods, carefully remove any restraints and secure any loose sections. Employ safe lifting techniques; stay away from jerky or excessively forceful motions.

By following these steps, you can ensure the proper loading and unloading of goods onto a transport rack, minimizing the risk of damage and ensuring the safe transportation of goods.

How to Optimize Transport Rack Efficiency

Optimizing transport rack efficiency can lead to significant benefits in terms of time-saving, cost reduction, and an increase in productivity. Here are some strategies to optimize the efficiency of your transport racks:

-

Standardization: When it is feasible, use standardized transport rack sizes and arrangements to improve interchangeability and compatibility. This makes it simpler to arrange and stack items, which promotes more effective use of available storage space.

-

Automation: To expedite the handling of transport racks, explore automation options including robotic loading and unloading, conveyor systems, or automated guided vehicles. In reality, automation can eliminate manual handling and increase overall efficiency.

-

Dock-to-Dock Movements: Minimize the need for manual transfers and handling by using transport racks that can be loaded at the source and unloaded directly at the destination. As a result, this will eliminate the need for repackaging or multiple movements, reducing the risk of damage and improving efficiency.

-

Barcoding or RFID: Implement barcoding or radio-frequency identification (RFID) technology to track and manage transport racks more efficiently. This allows for easy identification, inventory control, and tracking throughout the supply chain.

-

Optimized Storage Layout: Analyze your facility’s storage structure and rack positioning to enhance space efficiency while minimizing unnecessary motions. Optimize the flow of items and enable simple access to the racks, which will save handling time and increase efficiency.

-

Collaborative Planning: Collaborate with suppliers, customers, and logistics partners to maximize the use of transport racks throughout the supply chain. Consider factors like load consolidation, backhauling opportunities, and efficient loading and unloading procedures.

By implementing these strategies and continuously evaluating and improving your transport rack operations, you can achieve optimal efficiency and enhance the overall productivity of your logistics operations.

Transport Rack Customization Options

Many manufacturers offer customization options to tailor transport racks to specific needs. These customization options allow businesses to optimize the design and functionality of the racks for their unique requirements. Here are some common transport rack customization options:

-

Size and Dimensions: Transport racks can be customized to specific dimensions to fit the goods being transported and the available storage space. Custom sizing ensures maximum space utilization and compatibility with material handling equipment.

-

Load Capacity: Manufacturers can design transport racks with varied load capabilities based on the weight needs of the objects being transported. This ensures that the racks can securely support the specified loads.

-

Adjustable Dividers: Dividers in the transport rack can be adjusted or removed. This provides versatility in grouping various-sized commodities and adjusting to changing storage requirements.

-

Additional Safety Features: Manufacturers can incorporate additional safety features, such as corner protection, anti-tipping mechanisms, or load restraints, to ensure the safe handling and transportation of goods.

-

Surface Finish: Transport racks can be customized with different surface finishes, such as paint or powder coating, to enhance durability, aesthetics, or resistance to environmental factors.

-

Labeling and Identification: Manufacturers can add personalized labeling or identifying options to the transport racks. These may include barcodes, RFID tags, or specialized labeling requirements dictated by industry or compliance rules.

-

Collapsible Design: When not in use, some transport racks can be designed with folding capabilities that enable space-saving storage. For companies with limited storage space or for returnable transit packing, this functionality is especially helpful.

By taking advantage of these customization options, businesses can design transport racks that precisely meet their unique requirements, ensuring optimal performance, efficiency, and safety.

Sustainability and Environmental Considerations in Transport Rack Design

Sustainability and environmental issues are key in the design and use of transport racks. Businesses that prioritize sustainability can lower their carbon footprint, cut waste, and contribute to a better future. Here are some key sustainability and environmental considerations in transport rack design:

-

Material Selection: Select environmentally friendly materials, such as those that come from sustainable, renewable, or recyclable sources. Take into account the material’s entire life cycle, which includes extraction, manufacturing, usage, and disposal.

-

Recyclability: Choose transport racks that are recyclable at the end of their life. This reduces waste and allows items to be reused or repurposed, thereby contributing to the circular economy.

-

Returnable Transit Packaging: Consider the use of returnable transit packaging, in which transport racks can be returned and reused rather than discarded after each use. Consequently, this lowers waste and conserves resources in the long run.

-

Optimized Storage and Transportation: Make use of transport racks that optimize space usage to cut down on the amount of extra storage and transit trips. Efficient transportation planning can minimize fuel consumption, emissions, and overall environmental impact.

-

Collapsible Design: If it is practical for your operations, consider adopting collapsible transport racks. These racks enable more effective storage and transit of empty racks, saving space and optimizing return trips.

-

Packaging Reduction: Properly design racks and dividers to reduce the need for additional packaging materials, such as shrink wrap or bubble wrap. This minimizes waste and lowers the environmental impact associated with disposable packaging.

By incorporating these sustainability considerations into transport rack design and operations, businesses can contribute to a more sustainable and eco-friendly industry.

Conclusion

Transport racks are essential assets for efficient and secure cargo handling in a wide range of industries. Their design encourages the safe and orderly transfer of items, reducing damage and improving operating efficiency. Companies that invest in long-lasting and well-designed transport racks can improve productivity, save money, and protect valuable products during transit. Transport racks’ versatility and durability make them a fantastic solution for any firm looking to streamline logistics and ensure the safe transit of goods.