Explore innovative designs, practical applications, and the numerous benefits of utilizing a wine barrel rack for your facility.

Read MoreSteel Stackable Pallets: The Ultimate Guide to Elevate Storage

What are Steel Stackable Pallets?

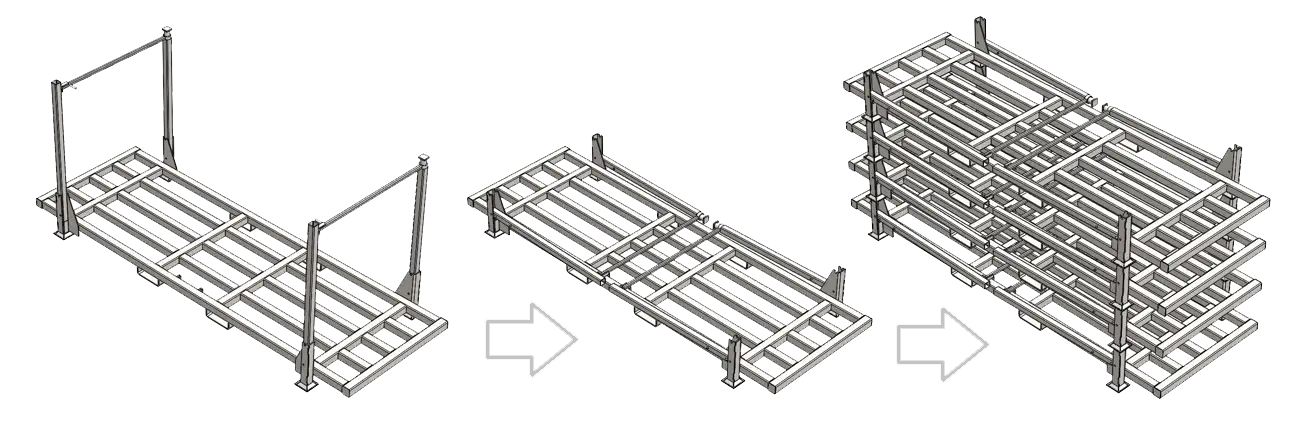

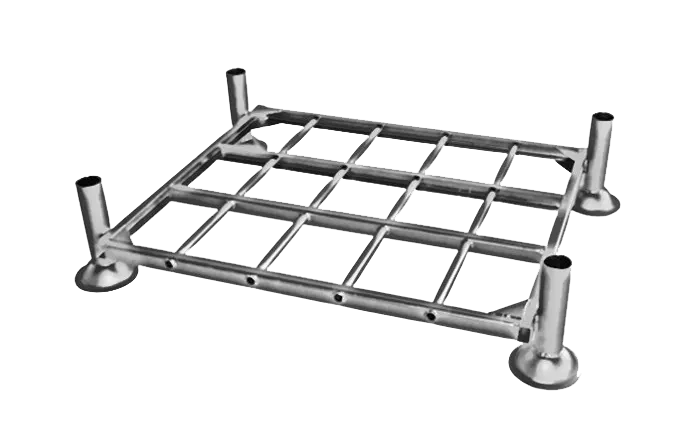

Steel stackable pallets are a type of storage solution that is designed to efficiently organize and store goods in various industries. These pallets are made from high-quality steel, providing strength and durability for heavy-duty applications. They are specifically designed to be stacked on top of each other, allowing for optimal use of vertical space in warehouses, distribution centers, and other storage facilities.

Key Takeaways:

- -> Steel stackable pallets are specially designed to efficiently store goods in various industries.

- -> These pallets are made from high-quality steel, providing strength and durability.

- -> They are designed to be stacked on top of each other, maximizing vertical space utilization.

The Benefits of Steel Stackable Pallets

Why choose steel stackable pallets?

When it comes to storage solutions, these pallets offer several advantages over other options. Their sturdy construction ensures that they can handle heavy loads, making them suitable for industries such as manufacturing, automotive, and construction. Additionally, the stackability feature allows for better space utilization, optimizing storage capacity and reducing the footprint required.

Key advantages of using steel stackable pallets:

-

Durability: These pallets are built to last. They can withstand harsh environments, heavy loads, and frequent use without compromising their structural integrity.

-

Versatility: These pallets are available in various sizes and configurations to accommodate different types of products and storage requirements. Some designs even have removable side frames or collapsible features, providing even more flexibility.

-

Space efficiency: Unlike traditional pallets, steel stackable pallets can be easily stacked on top of each other to make the most of vertical space. This not only maximizes storage capacity but also facilitates efficient inventory management and retrieval.

Cost-effective and sustainable solution:

In addition to their functional benefits, these pallets also offer cost-effectiveness and sustainability advantages. While they may have a higher upfront cost compared to other types of pallets, their long lifespan and durability result in lower replacement and maintenance costs in the long run. Furthermore, steel is a recyclable material, making these pallets an environmentally friendly choice.

Different Types of Steel Stackable Pallets

Various designs and configurations of steel stackable pallets:

These pallets come in a range of designs and configurations, each catering to specific storage needs. Some common types include:

-

Rackable Pallets: These pallets feature runners or ledges that allow them to be securely stored in racking systems. They are designed to withstand the weight and pressure of being placed on pallet racking beams.

-

Nestable Pallets: Nestable steel pallets are designed in such a way that they can nest inside each other when not in use. This feature helps save space during transport and storage when the pallets are empty.

-

Collapsible Pallets: Collapsible steel pallets have hinged or removable side frames, allowing them to be collapsed for space-saving storage when not in use. This makes them particularly advantageous for industries with limited storage capacity.

Choosing the right type for your needs:

When selecting the right type of steel stackable pallets for your specific needs, consider factors such as the weight and dimensions of your products, the storage environment’s conditions, and any specific handling requirements. Consulting with a pallet expert or supplier can help you identify the most suitable option for your industry and application.

How Do Steel Stackable Pallets Work?

Understanding the functionality of steel stackable pallets:

These pallets work by utilizing their sturdy construction to safely support and store goods in a stacked configuration. They generally have a flat surface with openings or gaps that allow for fork or crane access during loading, unloading, and transportation. The design of these pallets ensures stability and prevents product damage while maximizing available space.

Features that enhance efficiency:

To further enhance efficiency, these pallets may include additional features such as:

- Anti-slip surfaces: Some designs incorporate anti-slip coatings, patterns, or materials to prevent product slippage and improve stability during handling and transportation.

- Forklift pockets: Certain pallets may have forklift pockets integrated into their design, making it easier for forklift operators to handle and position them.

- Edges and corners protection: Steel stackable pallets can be equipped with edge protectors or corner reinforcements to ensure that they remain intact and safe during stacking and transportation.

Key Considerations for Selecting Steel Stackable Pallets

Factors to keep in mind when choosing steel stackable pallets:

When selecting these pallets, it’s important to consider several factors to ensure they meet your specific needs:

-

Load capacity: Determine the weight and dimensions of the products you need to store and choose pallets with an appropriate load capacity rating to handle the required load.

-

Durability and strength: Assess the quality of the steel used in the pallets to ensure they can withstand the conditions in your storage environment and support the weight of your products without deformation or damage.

-

Compatibility: Ensure that the pallets are compatible with your existing equipment, such as forklifts, reach trucks, or pallet jacks, to facilitate seamless handling and transportation.

-

Ease of maintenance: Consider the maintenance requirements of the pallets and whether they can be easily cleaned, repaired, and maintained to ensure their long-term functionality.

By carefully evaluating these factors, you can select pallets that will effectively meet your storage requirements and provide long-lasting performance.

Maintenance and Longevity of Steel Stackable Pallets

Tips for extending the lifespan of your pallets:

To maximize the longevity of your steel stackable pallets and ensure their continued functionality, implement the following maintenance practices:

-

Regular inspections: Conduct routine inspections to check for any signs of damage, such as bends, cracks, or rust. Promptly address any issues to prevent further deterioration.

-

Cleaning: Regularly clean the pallets to remove any debris or contaminants that can cause damage or compromise hygiene standards. Use appropriate cleaning methods and materials for steel surfaces.

-

Avoid overloading: Be mindful of the load capacity of your pallets and avoid exceeding it to prevent structural damage or failure. Distribute the load evenly across the pallet’s surface.

Proper care and maintenance guidelines:

In addition to the above tips, follow these guidelines to ensure proper care and maintenance of your steel stackable pallets:

-

Store in a dry environment: Keep your pallets in a dry, well-ventilated area to prevent moisture buildup and minimize the risk of corrosion.

-

Protect against impacts: Minimize the risk of impact damage by handling pallets with care and storing them in a way that avoids collisions with other objects or equipment.

-

Implement safe stacking practices: When stacking pallets, ensure that they are properly aligned and supported to prevent tipping or collapse. Follow stacking guidelines provided by the pallet manufacturer.

Proactively maintaining and caring for your steel stackable pallets will help extend their lifespan and ensure their ongoing performance and safety.

How to Properly Use Steel Stackable Pallets

Best practices for loading and unloading:

To ensure safe and efficient loading and unloading operations with these pallets, follow these best practices:

-

Secure the load: Ensure that products are properly secured on the pallets to prevent them from shifting or falling during handling and transportation. Utilize appropriate strapping or stretch wrapping techniques.

-

Use proper lifting techniques: When using forklifts or other lifting equipment, follow proper lifting techniques and load placement guidelines to avoid accidents or damage to the pallets and products.

-

Inspect pallets before use: Prior to each use, check the condition of the pallets for any signs of damage or defects. Do not use damaged or compromised pallets as they may pose safety risks.

Ensuring safety during stacking and storage:

When stacking and storing steel stackable pallets, prioritize safety to prevent accidents and maintain the integrity of both the pallets and the stored products. Here are some key safety considerations:

-

Avoid exceeding stacking limits: Adhere to the recommended stacking limits provided by the manufacturer to prevent instability and the risk of collapse.

-

Ensure stable stacking configurations: Ensure that the pallets are properly aligned and nestled together to create a stable stacking configuration. Use edge protectors or corner reinforcements as needed.

-

Provide clear markings: Clearly mark stacking heights and load capacities on the pallets to prevent exceeding their limits and to provide clear handling instructions for employees.

By following these proper usage and safety guidelines, you can optimize the performance of your pallets and ensure a safe working environment.

Implementing Steel Stackable Pallets in Your Industry

Applications of steel stackable pallets across various industries:

Steel stackable pallets have numerous applications across various industries that require efficient storage and transportation solutions. Some common industries that benefit from the use of these pallets include:

-

Manufacturing: These pallets are widely used in manufacturing industries to store and transport raw materials, components, and finished products.

-

Automotive: The automotive industry utilizes these pallets for the storage and logistics of vehicle parts, engines, and other components.

-

Construction: Steel stackable pallets are suitable for construction sites as they can withstand heavy loads and provide sturdy support for construction materials such as bricks, cement bags, and steel rods.

-

Retail and e-commerce: These pallets are instrumental in organizing and storing products in retail distribution centers and e-commerce warehouses, where inventory turnover is high.

Success stories and case studies:

To gain insights into the successful implementation of steel stackable pallets in different industries, study success stories and case studies. These stories can provide valuable practical examples and inspire innovative storage solutions tailored to your industry and specific requirements.

Factors to consider when purchasing:

Consider the following factors when purchasing steel stackable pallets to ensure you make an informed decision:

-

Quality: Look for pallets made from high-quality steel and fabricated with precision and attention to detail to ensure durability, strength, and reliability.

-

Customization options: Determine whether the manufacturer offers customization options such as size, configuration, and additional features to meet your specific storage needs.

-

Customer support: Assess the manufacturer’s reputation for customer support, including responsiveness, warranty policies, and availability of replacement parts.

By carefully evaluating these factors, you can select the right manufacturer and supplier for your pallets, ensuring a reliable and efficient storage solution.

Cost Analysis: Steel Stackable Pallets vs. Alternatives

Comparing the cost-effectiveness of steel stackable pallets:

When evaluating the cost-effectiveness of these pallets compared to alternative options, consider the following aspects:

-

Initial investment: Steel stackable pallets may have a higher upfront cost compared to other materials such as wood or plastic. However, their longer lifespan and durability can result in cost savings over time.

-

Maintenance and replacement costs: Assess the maintenance requirements and replacement frequency of different pallet materials. These pallets generally require less maintenance and have a longer lifespan, reducing overall costs.

-

Storage efficiency: Consider the space-saving benefits of these durable pallets. The ability to stack them vertically can significantly optimize storage capacity, potentially reducing the need for additional storage space and associated costs.

Perform a thorough cost analysis, factoring in the above aspects, to determine whether the initial investment in these pallets outweighs the long-term cost benefits compared to alternative materials.

Environmental Impact of Steel Stackable Pallets

Sustainability benefits of steel stackable pallets:

These pallets offer several sustainability benefits, making them an eco-friendly storage solution:

-

Recyclability: Steel is a highly recyclable material. At the end of their lifecycle, steel stackable pallets can be recycled and used to manufacture new steel products, reducing the demand for virgin materials.

-

Longevity and reduced waste: The durability of these pallets results in a longer lifespan compared to alternative pallet materials. This reduces the need for frequent replacement and minimizes waste generation.

-

Reduced resource consumption: By maximizing storage space through vertical stacking, steel stackable pallets contribute to more efficient use of storage facilities, reducing the overall land area required for storage and minimizing resource consumption.

Recycling and disposal options:

When it’s finally time to dispose of your pallets, explore recycling options. Contact local recycling centers or metal scrap yards to inquire about their recycling programs and processes. By responsibly recycling your pallets, you contribute to the circular economy and minimize the environmental impact.

Conclusion: The Perfect Storage Solution with Steel Stackable Pallets

Steel stackable pallets offer an efficient and durable solution for storage and transportation needs across various industries. Their strength, versatility, and space-saving features make them a preferred choice for businesses looking to optimize their storage capacity and reduce costs. By carefully considering the factors discussed in this guide and selecting reputable manufacturers, you can implement these pallets that meet your specific requirements, improve operational efficiency, and contribute to a sustainable future.

Customize Your Own & Get a FREE Estimate!

Simply e-mail us at sales@plexformps.com with all your information

OR call us today & speak to one of our packaging professionals