Discover how stack racks can maximize storage space, improve organization, and enhance efficiency in various industries.

Read More

What is a steel component rack?

A steel component rack is a storage solution specifically designed for industrial settings. It is a versatile and sturdy shelving system that provides a safe and efficient way to store various components, tools, and equipment. Made from high-quality steel, these racks can withstand heavy loads and are built to last.

Formal definition of a steel component rack:

A steel component rack is a freestanding or wall-mounted storage structure made of steel, typically constructed with adjustable shelves or bins to accommodate different sizes and weights of components. It is designed to maximize space utilization and provide easy accessibility to stored items, improving overall organization and efficiency in industrial settings.

Common uses and applications of steel component racks:

Steel component racks are widely used in a variety of industrial settings, including manufacturing plants, warehouses, workshops, and automotive repair shops. They can store a variety of components, including machinery parts, electronic components, hardware, tools, small parts, and more. These racks provide a practical storage option, allowing for quick and simple access to stored products, which improves workflow and productivity.

Advantages of using steel component racks:

There are several advantages to using steel component racks in industrial settings:

-

Durability: Steel racks are strong and resistant to wear and tear. They can withstand heavy loads and constant use, making them highly durable and long-lasting.

-

Versatility: Steel component racks are available in a variety of sizes and configurations, allowing for customization to meet individual storage requirements. Also, they can be adjusted, enlarged, and altered as needed.

-

Space optimization: With their adjustable shelves or bins, steel component racks optimize storage space, enabling efficient utilization of available vertical and horizontal space.

-

Easy accessibility: These racks allow for simple access to stored products, minimizing the time required to retrieve components and increasing production.

-

Safety: Steel racks are designed to meet safety standards and provide secure storage for components, minimizing the risk of damage or accidents.

Benefits and importance of steel component racks in industrial settings

Steel component racks play a crucial role in industrial settings and offer several benefits:

-

Enhanced organization: By providing a structured storage solution, steel component racks help organize components systematically, making it easier to locate and retrieve specific items quickly. Ultimately, this eliminates unnecessary downtime and improves overall efficiency.

-

Reduced clutter: Steel component racks reduce clutter and produce a clean and ordered environment, promoting overall aesthetics and worker safety.

-

Inventory management: These racks improve inventory management by providing clear visibility and simple access to stored components. This allows for efficient tracking of stock levels, reducing the risk of overstocking or running out of essential components.

-

Improved productivity: With easy access to components, workers can quickly retrieve what they need, reducing downtime and improving productivity. The streamlined storage system eliminates time wasted searching for items, enabling workers to focus on their tasks.

-

Cost savings: Properly arranged and stored components are less likely to be damaged, requiring fewer replacements. Ultimately, this translates into long-term cost reductions.

Types of steel component racks:

There are different types of steel component racks available, each designed to cater to specific storage requirements.

1. Single-sided steel component racks:

Single-sided steel component racks are typically designed to be placed against a wall or partition, maximizing the use of limited space. They feature shelves or bins on one side, providing easy access to stored items from the front.

Features and benefits of single-sided steel component racks:

- Efficient utilization of space: These racks are ideal for narrow aisles or small storage areas where space is limited.

- Easy accessibility: Workers can easily access items from one side of the rack, allowing for quick retrieval and replenishment.

- Versatility: Single-sided racks can be configured with adjustable shelves or bins to accommodate different component sizes.

- Cost-effective solution: These racks are generally more affordable compared to double-sided or mobile racks.

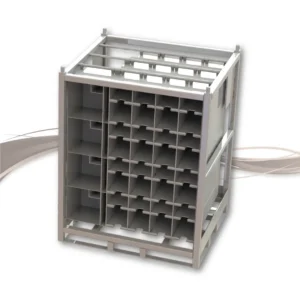

2. Double-sided steel component racks:

Double-sided steel component racks have shelves or bins on both sides, giving access from either side. They are appropriate for open spaces where space is not an issue and where multiple people need to access the components simultaneously.

Features and benefits of double-sided steel component racks:

- Enhanced accessibility: With components accessible from both sides, these racks allow for simultaneous retrieval and restocking by multiple workers, improving workflow efficiency.

- Flexibility: Double-sided racks can be positioned in the center of a storage space or aisle to provide easy access from both directions.

- Increased storage capacity: These racks offer more storage space compared to single-sided racks, making them suitable for larger inventories.

- Easy organization: Different types or sizes of components can be stored on each side, allowing for efficient categorization and easy identification.

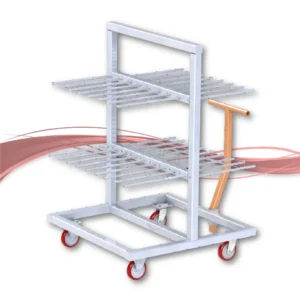

3. Mobile steel component racks:

Mobile steel component racks are equipped with wheels or casters, making them portable and easily mobile in an industrial environment. These racks are ideal for areas that require maximum flexibility and accessibility.

Features and benefits of mobile steel component racks:

- Flexibility: Mobile racks can be easily re-positioned or relocated to accommodate changing storage needs or workspace layouts.

- Space optimization: When necessary, these racks may be effortlessly relocated closer to workstations, which reduces wasted movement and saves time.

- Versatility: Single-sided and double-sided mobile racks are among the configurations that are available, providing a variety of storage choices.

- Maneuverability: The wheels or casters on mobile racks enable smooth movement across different surfaces, making them easy to handle.

How do steel component racks work?

Steel component racks are made to offer effective organizing and storage. Usually, they are made of a steel frame with movable bins or shelves. The components are placed on the shelves or in the bins, ensuring they are easily accessible and well-organized.

Customization is possible with the adjustable shelves, which store components of different sizes and forms. This functionality is very helpful for industries with a wide range of component needs. Due to their strong steel construction, the racks can support large loads without collapsing or endangering users’ safety.

Steel component racks can be designed to meet the specific requirements of an industrial setting. Therefore, this flexibility will enable excellent space usage and easy item retrieval. Depending on the available space and workflow requirements, the racks can be arranged in aisles, against a wall, or in the center of a room.

Factors to consider when choosing a steel component rack:

When selecting a steel component rack for your industrial setting, several factors need to be considered to ensure you choose the most suitable option. Here are some key considerations:

1. Rack capacity and weight limit:

Determine the weight and size of the components you need to store, then select a rack with a suitable weight capacity. It is critical to consider not just the weight of individual components, but also the maximum weight that the rack can support.

2. Rack dimensions and space availability:

Measure the available space in your industrial location to establish the rack’s acceptable dimensions and design. Consider any height or width limits to ensure that the rack fits perfectly in the designated area.

3. Durability and sturdiness:

Look for steel component racks made of high-quality materials and designed to resist heavy weights and continuous use. The structure should be strong enough to protect the stored components and prevent damage.

4. Accessibility and ease of use:

Consider how easy you want to reach components from the rack. Depending on the workflow and frequency of access, you may require features like adjustable shelves, bins, or easy-roll mechanisms to improve accessibility.

How to choose the right steel component rack for your needs:

Choosing the right steel component rack involves a thoughtful evaluation of your storage requirements and the available space. Follow these steps to select the most suitable rack:

1. Assess your storage requirements:

Consider the size, weight, and quantity of the components that need to be stored. Determine the number of shelves or bins required and the optimal spacing between them.

2. Determine the space available:

Measure the available storage area, taking into account any restrictions such as height or width limitations. Basically, this will help determine the appropriate dimensions and configuration of the rack.

3. Consider the weight and size of your components:

Choose a rack with a weight capacity that can comfortably accommodate the components you need to store. In essence, you want to ensure that the dimensions of the shelves or bins can accommodate the size of your components.

4. Evaluate the durability and construction quality:

Look for racks built of high-quality, sturdy steel that can sustain large loads and repeated use. Check for features like reinforced frames and adjustable shelves, which add to the rack’s overall strength and endurance.

5. Determine the accessibility and retrieval method:

Consider how frequently and easily you need to access the components. Choose a rack configuration that allows for easy retrieval, whether it is through adjustable shelves, bins, or a mobile design.

How to maximize the efficiency of your steel component rack system:

To make the most of your steel component rack system and optimize its efficiency, consider implementing the following strategies:

1. Proper organization and labeling:

Ensure that the components are organized logically and consistently within the rack system. Labels or color-coded markers can help you readily identify specific items, making retrieval faster and more efficient.

2. Implementing a tracking system:

Consider implementing a tracking system, such as barcodes or RFID tags, to streamline inventory management. Essentially, this enables easy identification and tracking of components and reduces the risk of inaccurate stock counts.

3. Regular inventory management:

Continuously monitor and manage your inventory to avoid overstocking or running out of critical components. Regularly update stock records and conduct audits to ensure that the restocking process is accurate and efficient.

Potential challenges and solutions:

While steel component racks offer numerous benefits, there may be certain challenges you may face. Here are two common challenges and their potential solutions:

1. Overloading and weight distribution:

Racks may become overcrowded or unbalanced if components are not distributed or kept correctly, which could provide safety risks. To get around this, make sure that the parts are spaced uniformly across the rack and always abide by the manufacturer’s recommended weight restrictions.

2. Limited space and expansion needs:

If your industrial setting has limited space or future expansion needs, it can be challenging to accommodate additional racks. For that reason, consider using double-sided or mobile racks to maximize storage capacity without compromising valuable floor space.

Conclusion

Steel component racks serve as essential storage solutions for industrial settings, offering durability, versatility, and accessibility. Their capacity to increase organizational skills, inventory management, and efficiency make them important in a variety of companies. You can select the best rack for your needs by carefully examining your individual storage requirements as well as considerations like weight capacity, dimensions, and accessibility. Proper maintenance and utilization of strategies for organization will increase the efficiency of your steel component rack system, assuring safe and streamlined operations in your industrial setting.