Explore innovative designs, practical applications, and the numerous benefits of utilizing a wine barrel rack for your facility.

Read MoreStack Racks: Maximizing Space, Minimizing Hassle

What are stack racks?

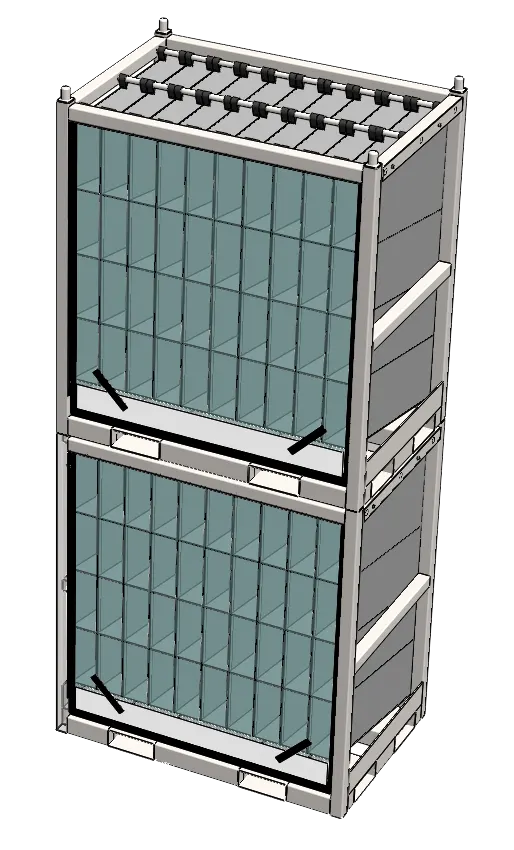

Stack racks are versatile storage solutions designed to maximize space utilization and improve efficiency in various industries. These racks are typically made of a sturdy metal frame and come in different sizes and configurations to accommodate different storage needs. In addition, the primary feature of stack racks is their ability to be stacked on top of each other, allowing for vertical storage and easy access to items.

Key Takeaways:

- -> Stack racks are storage solutions that maximize space utilization.

- -> They are made of a sturdy metal frame and can be stacked on top of each other.

- -> These racks provide easy access to stored items.

The benefits of using stack racks

There are numerous benefits to using these racks in your storage facility or warehouse. Some of the key advantages include:

-

Space Optimization: Stack racks allow for vertical storage, effectively utilizing the available space in your facility. By stacking items, you can increase storage capacity without the need for additional floor space.

-

Easy Accessibility: Accessing stored items is convenient with these racks. The ability to stack and unstack racks provides quick and easy access to specific items without having to move other inventory. As a result, this saves time and effort during the order fulfillment process.

-

Flexibility: Stack racks can be easily rearranged and reconfigured to accommodate changing storage needs. In fact, they can be easily adjusted to fit different sizes and types of items, making them a versatile storage solution.

-

Improved Organization: These racks facilitate better organization of inventory. By using racks to separate and categorize items, it becomes easier to locate specific products and maintain an efficient workflow.

Types of stack racks

These racks come in various types, designed to meet different storage requirements. Here are some common types:

-

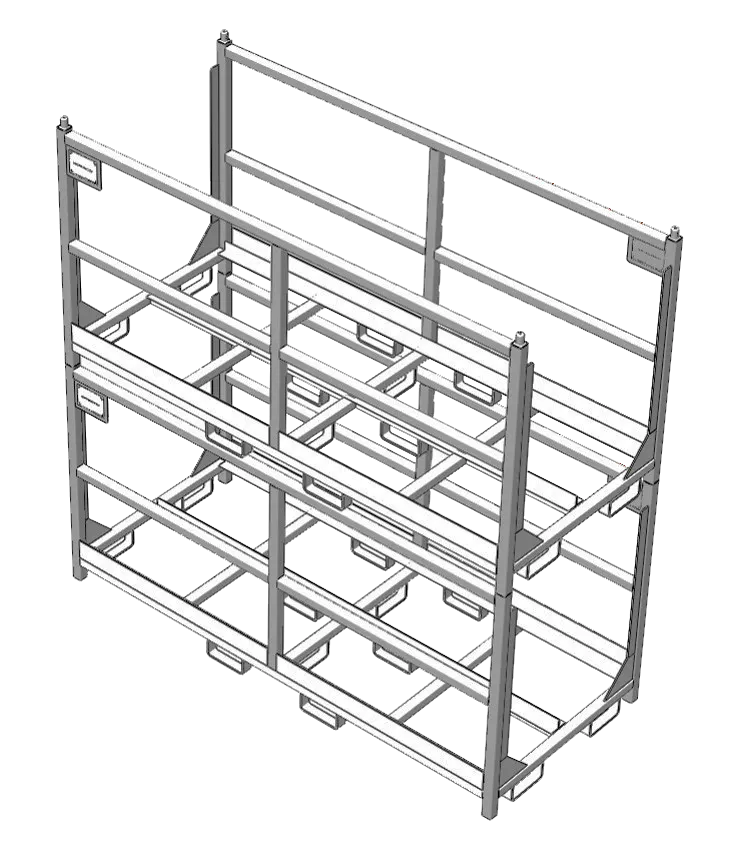

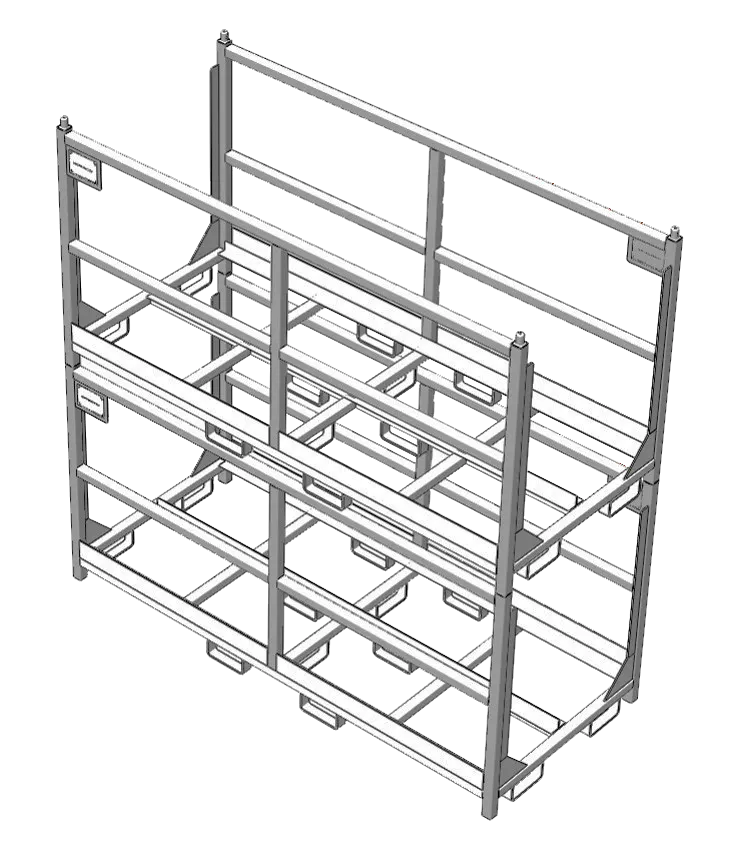

Collapsible Stack Racks: These racks are designed to be collapsible, which means they can be easily folded and stored when not in use. This feature makes them particularly useful for facilities with limited space.

-

Nestable Stack Racks: Nestable racks have a design that allows them to nest within each other when empty. This nesting feature helps save space during transportation or when the racks are not in use.

-

Stacking Pallet Racks: These racks have a pallet-like design and are used for storing bulk items that can be stacked on top of each other. They are commonly used in industries such as manufacturing, distribution, and warehousing.

How do stack racks work?

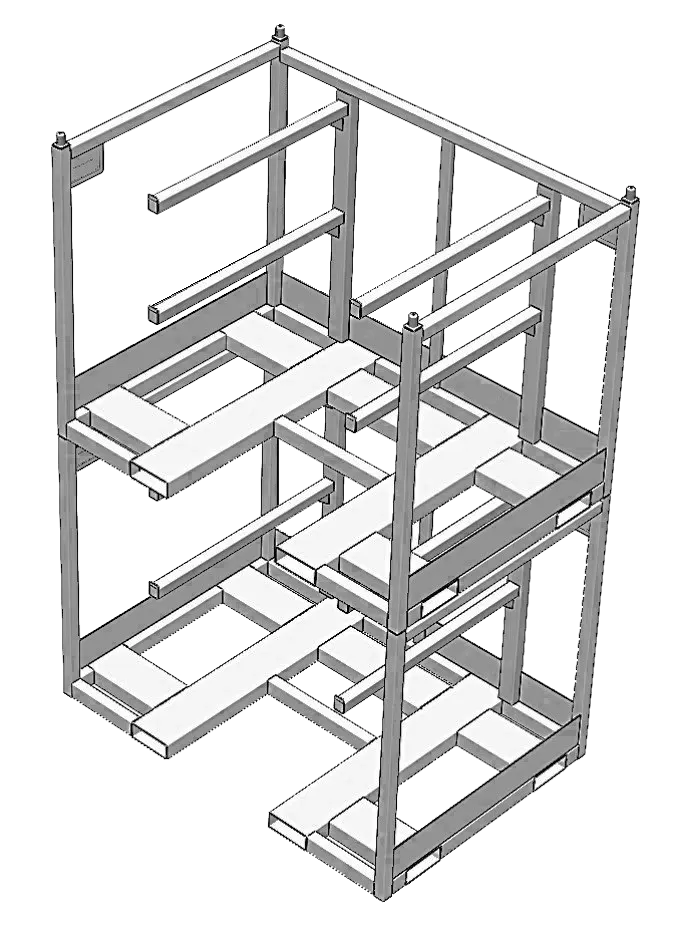

Stack racks work by providing a stable and secure structure for storing and organizing items. After all, these racks do have a strong metal frame that can support the weight of stacked items. Also, the design of the racks ensures stability and prevents items from shifting or falling during storage or transport.

These racks typically have four corner posts that provide stability and allow for easy stacking. Some racks may also have removable side panels to further secure the stacked items. In addition, these racks can be stacked several units high, depending on the weight capacity and stability requirements.

To use these racks, items are placed on the rack’s platform or base, ensuring proper weight distribution. The racks can then be stacked on top of each other, securing the items in place. In order to access to the items, one may do so by selectively unstacking the necessary racks.

Stack racks vs traditional storage methods

When comparing stack racks to traditional storage methods, such as shelving or pallet racking, several key differences become apparent.

-

Space Utilization: Stack racks excel at maximizing vertical space, allowing for higher storage capacity compared to traditional shelving. Traditional methods often require aisles for access, limiting the total amount of storage available.

-

Accessibility: These racks provide easy access to all items. Unlike pallet racking, which may require moving multiple pallets to reach a specific item, stack racks allow for selective unstacking, providing direct access to the desired items.

-

Flexibility: Stack racks offer greater flexibility in terms of rearranging and re-configuring storage space. Traditional shelving or pallet racking requires disassembling and reassembling, while these racks can be easily adjusted to fit changing storage needs.

-

Cost-Effectiveness: Stack racking can be a cost-effective option, especially for facilities with fluctuating inventory levels. Their versatility and ease of reconfiguration eliminate the need for constant investment in additional shelving or pallet racking.

How to choose the right stack rack

When choosing the right stack rack for your storage needs, consider the following factors:

-

Weight Capacity: Determine the weight capacity needed based on the items you intend to store. Ensure that the racks you choose have the required load-bearing capacity.

-

Size and Dimensions: Consider the size and dimensions of the items to be stored. Choose racks that can accommodate your specific product sizes while maximizing storage space.

-

Rack Design and Accessories: Assess the various design options and accessories available for these racks. This includes foldable or nestable racks, removable side panels, and additional customization options.

-

Durability and Material: Opt for stack racks made from sturdy materials such as steel to ensure durability and longevity. Consider the requirements of your environment, including resistance to corrosion or extreme temperatures.

How to use stack racks effectively

To make the most out of these racks, follow these guidelines for efficient use:

1. Organizing inventory with stack racks

Proper organization is essential for efficient storage and retrieval. Follow these tips to maximize storage capacity:

– Categorize items and assign specific racks for each category.

– Label these racks and use a comprehensive tracking system to easily locate items.

– Optimize vertical space by stacking racks close to their weight capacity while ensuring stability.

2. Stacking and securing items on stack racks

To ensure safe and secure storage, follow these practices:

– Distribute weight evenly on the stack rack platform to avoid instability.

– Use dividers or partitions to separate and secure smaller items within a stack rack.

– Place heavier items at the bottom of the stack to prevent toppling.

3. Transportation and logistics with stack racks

When using these racks for transportation or logistics, consider the following:

– Ensure proper loading and securing of stacked racks onto transport vehicles.

– Use additional securing methods, such as straps or stretch film, to prevent items from shifting during transit.

– Follow safe stacking and unstacking protocols to prevent accidents or injuries.

4. Maintenance and safety tips for stack racks

To maintain these racks and ensure a safe working environment, adhere to these guidelines:

– Regularly inspect stack racks for any signs of damage or wear. Replace damaged racks promptly.

– Ensure these racks are clean and free from debris to prevent damage to stored items.

– Train employees on proper stacking and unstacking techniques to minimize the risk of accidents.

Long-term storage solutions with stack racks

Stack racks can also be utilized for long-term storage needs. Consider the following tips for effective long-term storage:

- – Assess the storage requirements and adjust these racks accordingly, considering factors such as weight, size, and accessibility.

- – Regularly inspect stored items to prevent damage or deterioration over time.

- – Implement a proper rotation system to ensure proper inventory management and minimize the risk of stock becoming obsolete.

Stack rack accessories and customization options

Stack racks offer various accessories and customization options to enhance their functionality. Some common accessories include:

- 1. Removable side panels for securing stacked items.

- 2. Stackable bins or containers that fit neatly within the racks.

- 3. Dividers or partitions for separating and organizing items within a stack rack.

Customization options allow for tailor-made stack racks specific to your storage needs. These options might include adjustable height or width, custom paint finishes, or additional storage compartments.

Stack rack innovations and trends

The storage industry is continuously evolving, and new innovations and trends in these racks are emerging. Some of the latest advancements include:

- -> Smart stack racks equipped with sensors and RFID technology for real-time tracking and inventory management.

- -> Automated stack racks that integrate with warehouse management systems to streamline operations and reduce labor costs.

- -> Lightweight and eco-friendly stack rack materials that offer improved maneuverability and sustainability.

Conclusion

Stack racks provide an efficient and versatile storage solution for various industries. Their ability to maximize vertical space, improve accessibility, and facilitate organization makes them a valuable asset in any storage facility or warehouse. By considering factors such as weight capacity, size, and customization options, you can choose the right stack rack to meet your specific storage needs. Implementing proper stacking and safety guidelines will ensure the efficient and safe use of stack racks. As the industry evolves, embracing new innovations and trends will continue to enhance the effectiveness and efficiency of these racks in the future.

Customize Your Own & Get a FREE Estimate!

Simply e-mail us at sales@plexformps.com with all your information

OR call us today & speak to one of our packaging professionals