Explore innovative designs, practical applications, and the numerous benefits of utilizing a wine barrel rack for your facility.

Read MoreShipping Racks: Revolutionizing Logistics and Storage

Shipping racks are an essential component in the world of logistics and storage. The design of these racks optimize the transportation and storage of goods, ensuring efficiency, safety, and convenience in the supply chain.

The purpose of shipping racks is to provide a standardized and durable platform for the movement and storage of various products. Their design allows for easy stacking, handling, and transport, making them an indispensable tool in the shipping industry.

In the realm of logistics, shipping racks play a crucial role in streamlining operations and maximizing space utilization. By utilizing these racks, companies can efficiently organize and transport goods, reducing the risk of damage and optimizing the use of available storage space.

Shipping racks have revolutionized the transportation and storage of goods in several ways. Firstly, they have significantly improved the safety and security of goods during transit. The sturdy construction of these racks provides a protective barrier, minimizing the risk of damage caused by vibrations or impacts. This ensures that products reach their destination in optimal condition, reducing losses and enhancing customer satisfaction.

Furthermore, shipping racks have greatly enhanced the efficiency and speed of loading and unloading operations. With their standard dimensions and compatibility with various handling equipment such as forklifts and pallet jacks, these racks enable seamless movement and transfer of goods. This not only saves time but also minimizes the physical strain on workers, leading to increased productivity and reduced labor costs.

Another significant advantage of shipping racks is their ability to maximize storage space. By allowing for vertical stacking, these racks make efficient use of warehouse or container space, optimizing storage capacity. This is particularly beneficial in industries where space is limited or expensive, as it allows companies to store more products in a smaller footprint, ultimately reducing storage costs.

Importance and Benefits of Shipping Racks

Shipping racks are an essential component in the logistics and transportation industry. They securely store and transport goods, providing numerous benefits and ensuring the smooth flow of goods throughout the supply chain.

Improved Efficiency

One of the key benefits of using shipping racks is the improved efficiency they offer. By utilizing these racks, companies can optimize their storage space and maximize the capacity of their shipping containers or trucks. This means the transportation of goods are increased in a single trip, reducing the number of trips required and ultimately saving time and money.

Enhanced Protection

One of the main functions of shipping racks is to protect goods during transit. They are made from durable materials such as steel, providing a sturdy and reliable structure to support the items being shipped. Customizing these racks with additional features like padding or dividers further protects delicate or fragile items from damage. By using shipping racks, companies can minimize the risk of product breakage or loss, ensuring that goods reach their destination in excellent condition.

Streamlined Handling

Another advantage of these racks is their ability to streamline the handling process. They are compatible with various handling equipment, such as forklifts or pallet jacks, making it easier for workers to load and unload goods from containers or trucks. This not only saves time but also reduces the risk of injuries associated with manual handling. The standardized design of shipping racks ensures companies can easily store and organize goods, promoting efficient inventory management.

Cost Savings

Using shipping racks can lead to significant cost savings for companies. As mentioned earlier, the increased efficiency allows for more goods to be transported in a single trip, reducing transportation costs. Additionally, the enhanced protection provided by these racks minimizes the likelihood of product damage, reducing the need for returns or replacements. This can result in substantial savings in terms of both time and money.

Environmental Sustainability

Shipping racks also contribute to environmental sustainability. By optimizing the use of storage space and reducing the number of trips required, companies can reduce fuel consumption and carbon emissions associated with transportation. Additionally, these racks are made from recyclable materials, promoting a more sustainable approach to logistics and reducing waste.

In conclusion, shipping racks play a crucial role in the efficient and secure transport of goods. Their benefits include improved efficiency, enhanced protection, streamlined handling, cost savings, and environmental sustainability. By incorporating these racks into their logistics operations, companies can optimize their supply chain and ensure the timely and safe delivery of goods.

Types of Shipping Racks

Shipping racks are essential tools for companies to safely transport and store goods. They come in different styles and each design meets specific needs and requirements. Let’s explore some of the most common types of shipping racks:

1. Pallet Racks

Pallet racks are one of the most widely used types of shipping racks. They consist of horizontal beams supported by vertical frames, creating multiple levels of storage space. Pallet racks are commonly used in warehouses and distribution centers to store and organize palletized goods. They provide efficient use of vertical space, making it easier to access and retrieve items.

2. Wire Mesh Racks

Wire mesh racks are durable and versatile. These racks are made of welded wire mesh panels and are often used in industries where visibility and ventilation are important. Wire mesh racks are commonly used in automotive, food, and pharmaceutical industries to store and transport goods that require proper airflow and visibility for inspection.

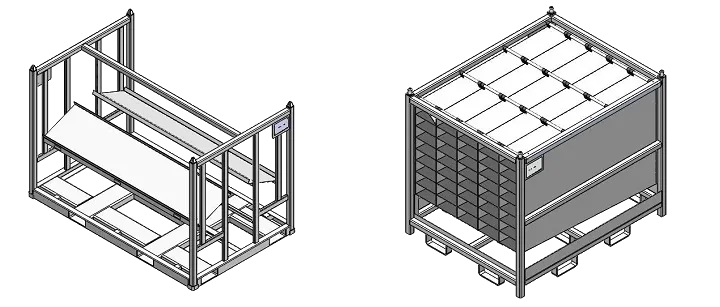

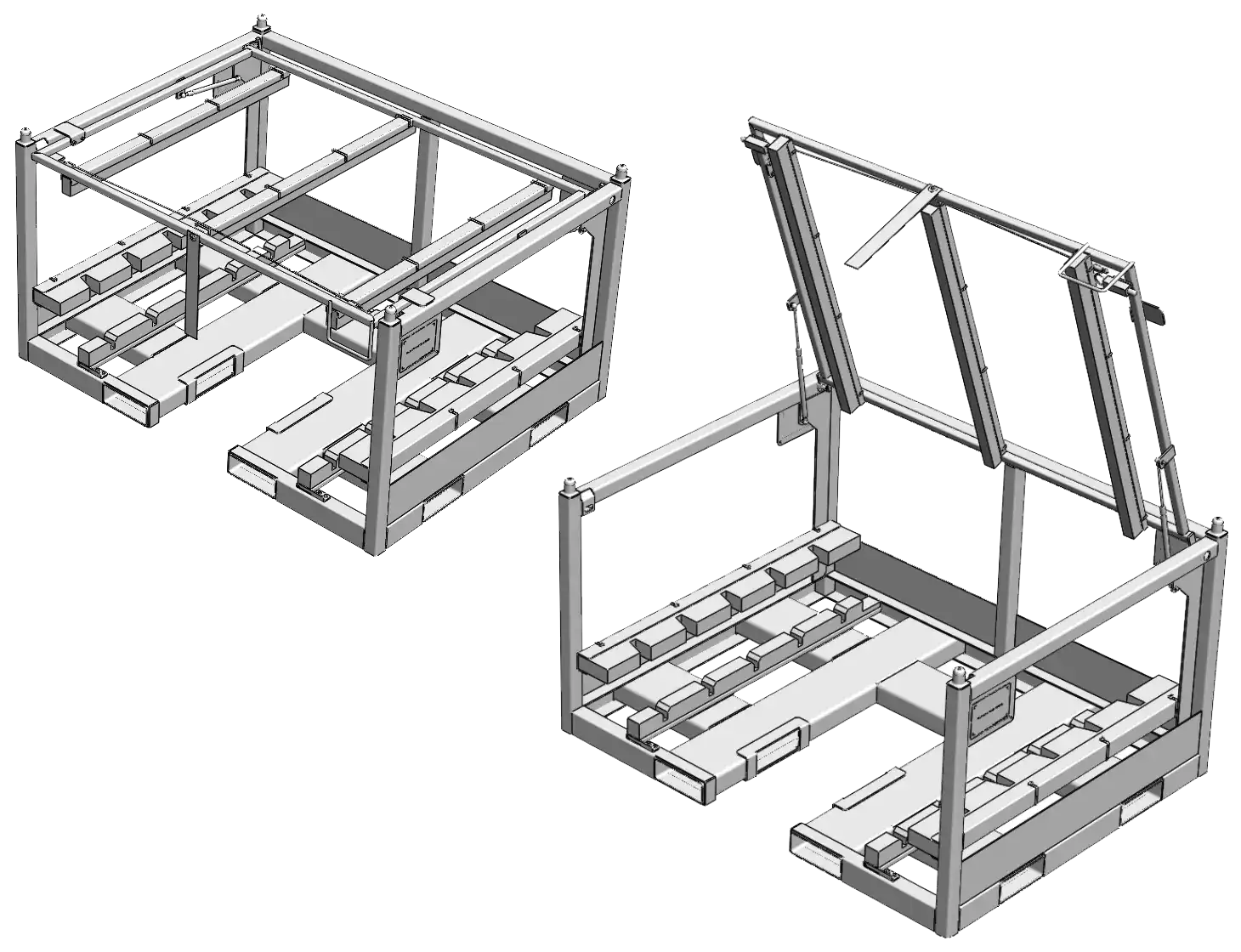

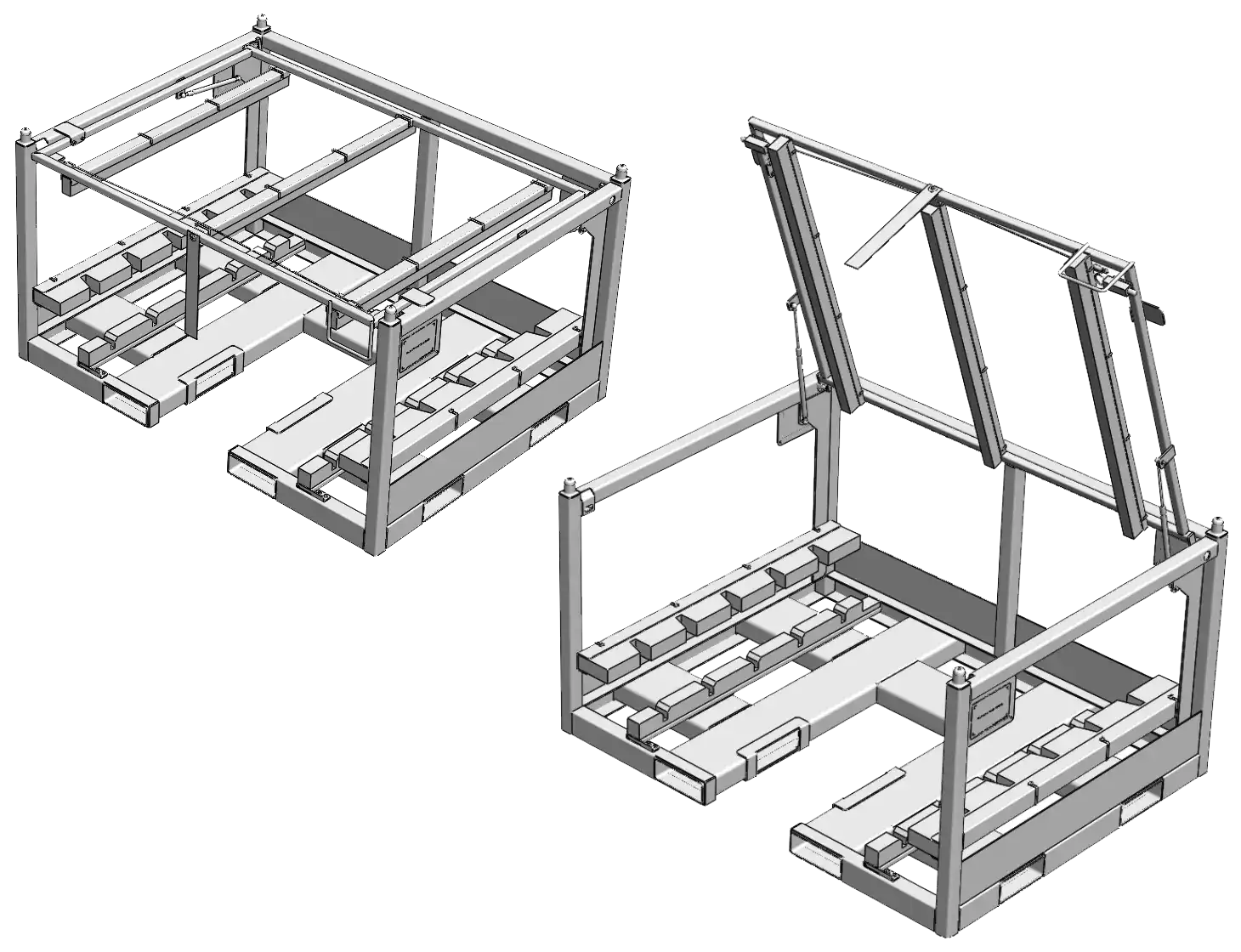

3. Stack Racks

Stack racks, also known as collapsible racks, are designed to be stacked when not in use. They are made of steel frames and wire mesh decking, providing a sturdy and secure storage solution. Industries that require temporary storage are a perfect fit for these stack racks, such as retail, logistics, and manufacturing. Their collapsible design allows for easy transportation and space-saving storage.

4. Cantilever Racks

Cantilever racks specialize in storing long and bulky items, such as lumber, pipes, and steel bars. They feature horizontal arms that extend from vertical columns, creating open storage space that allows for easy loading and unloading of materials. Cantilever racks are commonly used in construction sites, warehouses, and manufacturing facilities.

These are just a few examples of the different types of shipping racks available. Each type offers unique features and benefits, catering to specific storage and transportation needs in various industries.

Discuss the different types of shipping racks such as pallet racks, drive-in racks, push-back racks, and s. Each type should come with descriptions of their individual uses and which industries would benefit most from their use.

How to Choose the Right Shipping Racks

When it comes to shipping goods, choosing the right shipping racks is crucial for ensuring the safety and efficiency of your products. These racks are an essential part of the supply chain process, providing a secure and organized way to transport goods from one location to another.

There are several factors to consider when selecting shipping racks:

- Size: Consider the size of the items you will be shipping and choose racks that can accommodate them comfortably. It’s important to choose racks that provide enough space for your products to fit securely without being damaged during transport.

- Weight Capacity: Evaluate the weight of your products and select shipping racks that can handle the load. Racks with insufficient weight capacity can lead to accidents and damage to your goods.

- Material: The material of the shipping racks plays a significant role in their durability and strength. Common materials used for shipping racks include steel, aluminum, and plastic. Each material has its own advantages and disadvantages, so choose one that best suits your needs.

- Design: Consider the design of the shipping racks in terms of their stackability and collapsibility. Stackable racks allow for efficient use of space and collapsible racks are beneficial for easy storage when not in use.

- Compatibility: Ensure that the shipping racks you choose are compatible with the transportation method you will be using. For example, if you will be using a forklift to load and unload the racks, make sure they have the necessary features to facilitate this process.

By considering these factors, you can make an informed decision when choosing the right shipping racks for your specific needs. It is always recommended to consult with industry experts or suppliers to get personalized recommendations based on your requirements.

Customize Your Own & Get a FREE Estimate!

Simply e-mail us at sales@plexformps.com with all your information

OR call us today & speak to one of our packaging professionals