Discover how stack racks can maximize storage space, improve organization, and enhance efficiency in various industries.

Read MoreOptimizing Space: The Best Racks for Automotive Parts

What are racks for automotive parts?

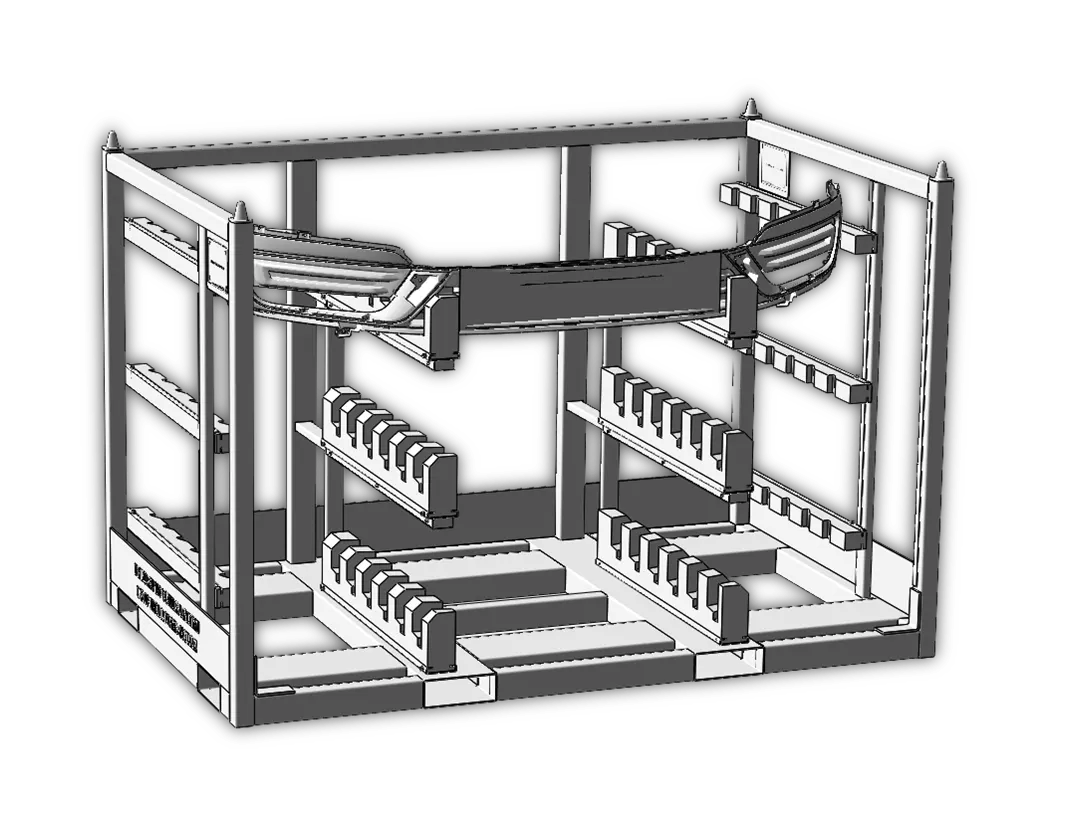

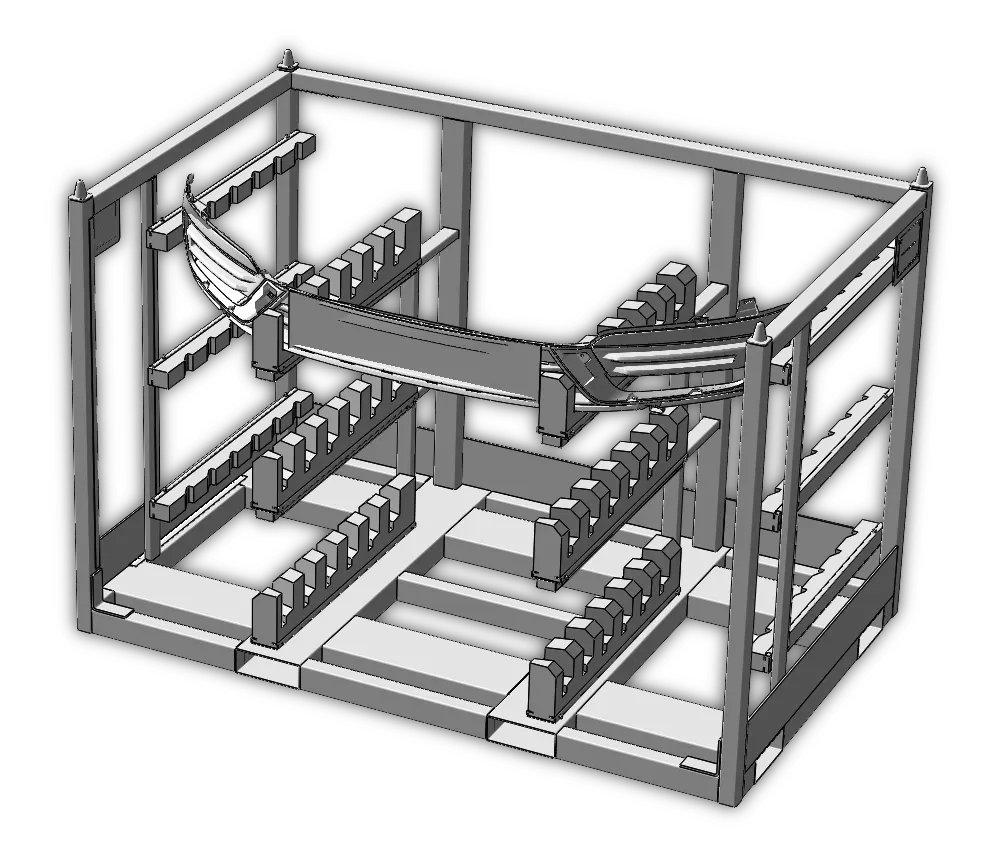

Racks for automotive parts are efficient storage solutions designed to maximize space and accessibility in automotive warehouses or garages. These racks provide a system of shelves or compartments that allow for the organized storage of various automotive parts, including small components, tools, and larger items such as tires or exhaust systems. By utilizing racks specifically designed for automotive parts, businesses can significantly improve their organization and efficiency in managing inventory.

Benefits of using racks for automotive parts

There are several notable benefits to using racks for automotive parts in your storage facility.

Improved organization and efficiency

One of the significant advantages of utilizing racks for automotive parts is improved organization. By providing a designated space for each part, racks make it easy to locate and retrieve specific items quickly. This allows for smoother workflow processes, reducing the time spent searching for parts and increasing overall efficiency. With a well-organized system in place, employees can easily identify available inventory and avoid unnecessary ordering of duplicate items.

Increased storage capacity

Another advantage of employing racks for automobile parts is the extra storage space they provide. These racks help you make the best use of vertical and horizontal space. Using vertical space, you can stack multiple racks to create multiple levels, considerably increasing your storage capacity. This is especially useful for firms with limited floor space, as racks make optimum use of vertical space, minimizing clutter and creating a more streamlined storage environment.

Enhanced safety measures

Racks for automotive parts also promote enhanced safety measures in your storage facility. By organizing and storing parts in specified areas, the risk of accidents and injuries caused by lost or incorrectly stored objects is considerably minimized. Properly constructed racks with suitable load capacity guarantee that heavy parts are securely kept, reducing the risk of accidents and damage. This not only enhances employee safety, but it also preserves the inventory’s integrity.

Types of racks for automotive parts

There are several types of racks available specifically designed for automotive parts storage. Each type offers unique features and advantages depending on your specific storage needs.

Vertical racks

Vertical racks are designed to maximize vertical space by utilizing multiple tiers of shelving. These racks are an ideal alternative for firms with limited floor space since they provide effective storage while decreasing the footprint. Also, vertical racks are ideal for storing small automotive parts including screws, nuts, and electrical components.

Horizontal racks

Horizontal racks provide easy access to parts stored on open shelves. These racks are ideal for heavier automobile components including tires, exhaust systems, and even full engines. Horizontal racks are often built with strong materials like steel to support the weight of heavy parts. In addition, their open design enables for easy identification and recovery of parts, increasing overall efficiency.

Mobile racks

Mobile racks are equipped with wheels or casters, allowing for easy movement and repositioning within the storage facility. These racks are useful for companies that require flexible storage layouts. Being able to rearrange the racks allows you to optimize your storage space or create temporary work areas as needed. Furthermore, mobile racks are very useful in automotive repair businesses, where parts may need to be moved between work stations.

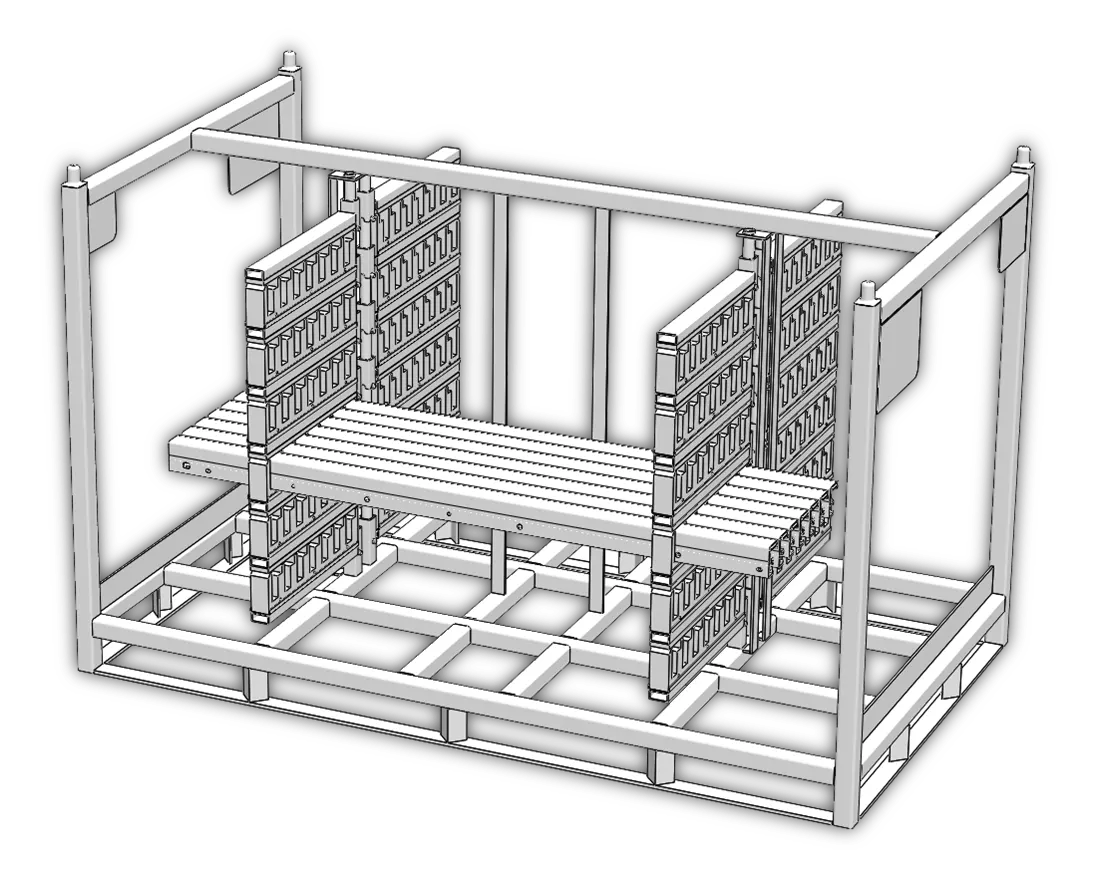

Adjustable racks

Adjustable racks provide the flexibility to customize shelf heights and configurations according to the size and shape of the automotive parts being stored. This allows for efficient use of space and prevents wasted areas between shelves. With adjustable racks, you can easily modify the storage layout as your inventory needs change over time.

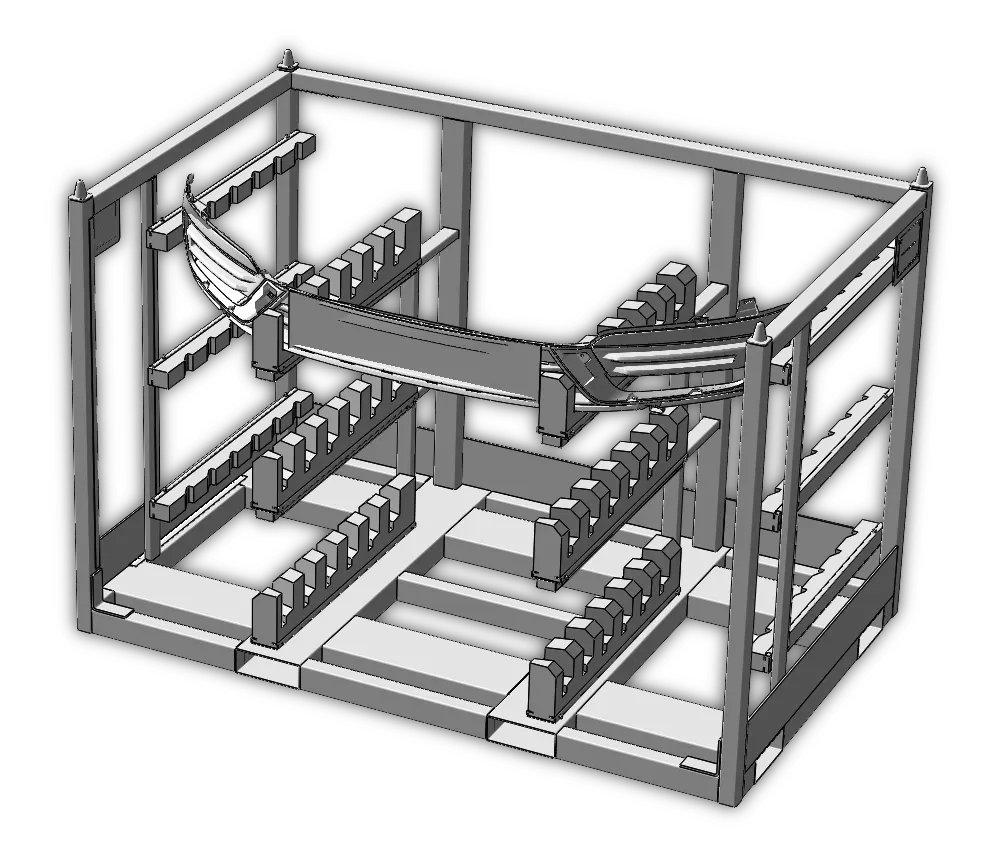

How racks for automotive parts work

Racks for automotive parts work by utilizing both vertical and horizontal space to maximize storage capacity while ensuring easy access to parts. These racks are built with durable materials such as steel or heavy-duty polymers that can handle the weight of various automobile parts.

By incorporating vertical tiers or open shelves, racks provide the ability to store a wide range of parts in an organized manner. This not only improves inventory management, but also allows for easy identification and retrieval of parts when needed. Additionally, the open design of most racks enables for simple visual identification of parts, which increases storage efficiency.

Moreover, racks for automotive parts allow for proper categorization and separation of different types of parts. By designating separate sections or shelves for individual parts, you can create an effective labeling system that allows staff to easily locate and retrieve items. As a result, this encourages more efficient processes and lowers the possibility of misplacing or losing valuable inventory.

Key features to consider when choosing racks for automotive parts

When choosing racks for automotive parts, it is essential to consider various key features to ensure optimal functionality and long-term durability.

Load capacity

The load capacity of the racks is an important factor to consider as it determines the weight that each shelf or tier can support. To avoid accidents or damage, choose racks that can withstand the weight of the parts being stored. Examine your inventory and select racks with the appropriate load capacity for your unique requirements.

Durability and material

The durability of the racks is vital for long-term usage. Automotive parts can be heavy and bulky, so choose racks made from robust and durable materials like steel or heavy-duty plastics. Ensure that the racks can bear the weight and impact of the items in order to keep them functional and prevent premature deterioration.

Size and dimensions

Consider the size and dimensions of the racks in relation to the available space in your storage facility. Measure the available floor space, ceiling height, and any other space constraints to ensure that the racks can be fitted correctly. Consider the size of the parts being stored and select racks that will accommodate the various products in your inventory.

Customization options

This could include adjustable shelves, modular designs, or the flexibility to add accessories like dividers or bins. Choosing racks with customizable options allows you to design a storage solution that perfectly aligns with your inventory needs.

How to optimize your storage with racks for automotive parts

To optimize your storage with racks for automotive parts, follow these steps:

1. Assess your storage needs

First, assess your storage needs by considering factors such as the number and size of parts you need to store, as well as any specific accessibility requirements. Essentially, this will help determine the type and quantity of racks you need to invest in.

2. Determine the appropriate rack type

Consider the space availability in your facility and the characteristics of the parts you need to store. Based on these factors, determine the appropriate rack type that will best suit your needs. For example, vertical racks are ideal for smaller parts, while horizontal racks are better suited for larger items.

3. Plan the layout and organization

Once you have chosen the appropriate rack type, plan the layout and organization of your storage space. Sort your parts according to type or purpose, then designate dedicated spaces or shelves for each group. Finally, implement a labeling system to make sure that parts are simple to identify and retrieve when needed.

4. Maintain your racks

Regularly inspect and clean the racks to keep them in optimal condition and prevent any potential safety hazards. In fact, proper maintenance will extend the lifespan of the racks and maintain the efficiency of your storage system.

Conclusion

In conclusion, utilizing racks for automotive parts is a highly beneficial solution for optimizing storage space and improving organization in automotive warehouses or garages. Understanding the many types of racks available, taking crucial aspects into account, and following suitable storage methods can help automotive organizations increase productivity and improve safety measures. With well-organized racks, you may expedite inventory management operations, shorten search times, and provide a safer work environment for your employees. Invest in racks for automotive parts and enjoy the benefits of improved organization, increased storage capacity, and enhanced safety in your automotive storage facility.

Customize Your Own & Get a FREE Estimate!

Simply e-mail us at sales@plexformps.com with all your information

OR call us today & speak to one of our packaging professionals