What is Steel Coil Racking?

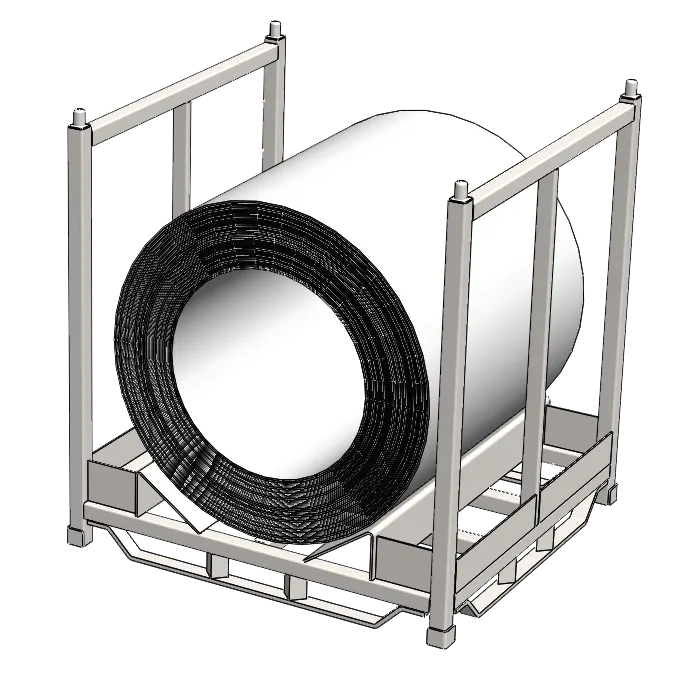

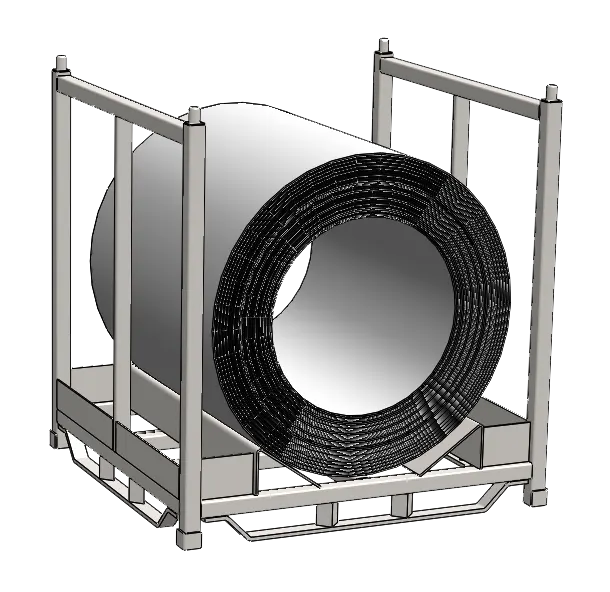

Steel coil racking is a specialized storage system designed to efficiently store and handle steel coils in warehouses and industrial settings. Steel coils, which are large and heavy cylindrical rolls of sheet metal, require a unique storage solution due to their size, weight, and specific handling requirements.

These racking systems are designed to safely and securely store these coils, maximizing the use of available space while ensuring quick and easy access to the coils when needed. In addition, these systems consist of upright frames, beams, and specially designed coil cradles that provide support and stability to the coils.

Benefits of Steel Coil Racking

Implementing a steel coil racking system in your warehouse offers several significant benefits for your storage operations. Some of the key advantages include:

-

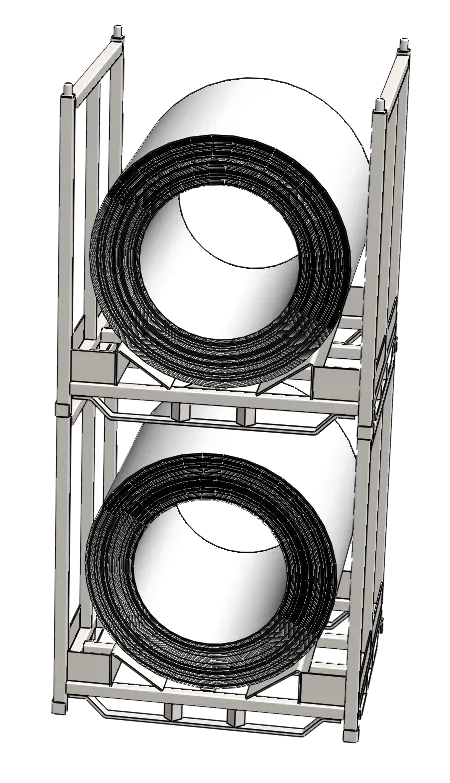

Optimized Space Utilization: Steel coil racking systems are designed to make the most efficient use of available space. By utilizing the vertical height of your warehouse, you can maximize storage capacity and free up valuable floor space for other operations.

-

Increased Efficiency and Productivity: Steel coil racking allows for easy access to individual coils, reducing the time and effort required to retrieve coils for production or shipping. Ultimately, this improves operational efficiency and overall productivity.

-

Enhanced Safety and Security: Steel coil racking systems are specifically designed to provide proper support and stability to steel coils, reducing the risk of damage or accidents. Basically, this will ensure the safety of your employees and protects your valuable inventory.

-

Improved Inventory Management: With steel coil racking, it becomes easier to organize and track your steel coil inventory. In essence, each coil can be assigned a specific location, making inventory management more efficient and accurate.

Types of Steel Coil Racking Systems

There are several types of steel coil racking systems available in the market, each with its own unique features and advantages. Here are some common types of these systems:

-

Coil Cradles: Coil cradles are adjustable storage racks that provide individual support for each coil. They can accommodate various coil sizes and have adjustable arms that can be positioned to support the coils at their core, minimizing the risk of deformation or damage.

-

Coil Storage Racks: Coil storage racks typically consist of upright frames and beams that provide multiple levels of storage for steel coils. Essentially, these racks can be customized to accommodate different coil sizes and load capacities.

-

Slit Coil Racks: Slit coil racks are specifically designed for storing slit coils, which are narrow strips of steel that have been cut from larger coils. Basically, these racks have dividers or compartments to keep the slit coils organized and easily accessible.

-

Vertical Coil Racks: Vertical coil racks are designed to store coils in a vertical position, utilizing the height of the warehouse. This type of rack is ideal for storing long or narrow coils that may not fit well in traditional horizontal racks.

How does Steel Coil Racking work?

Steel coil racking systems work by providing a stable and secure storage solution for steel coils. The specific configuration and design of the racking system may vary depending on the type of steel coil and the desired storage capacity.

Typically, the coils are placed on specially designed coil cradles or positioned between upright frames and beams. Also, the cradles or beams provide support and prevent the coils from rolling or shifting. This is particularly important for large and heavy steel coils that can pose risks if not properly supported.

The racking system allows for easy access to individual coils. Forklifts or cranes can be used to retrieve or replenish coils, making the process efficient and minimizing the risk of damage. Additionally, some racking systems may have features such as tilt and rotation mechanisms, allowing for more precise positioning of the coils.

A detailed explanation of the process:

-

Placement of Coil Cradles: The coil cradles are positioned on the racking system, ensuring that they are properly aligned and securely fastened.

-

Loading of Steel Coils: The steel coils are loaded onto the cradles or between the upright frames and beams. Care is taken to position the coils properly and evenly distribute the weight to ensure stability.

-

Securing and Supporting the Coils: The cradles or beams are adjusted to provide support and prevent the coils from rolling or shifting. This is crucial to maintain the integrity of the coils and prevent accidents or damage.

-

Retrieval and Replenishment: When a coil needs to be retrieved or replenished, a forklift or crane is used to safely lift and transport the coil. The storage system allows for easy access and retrieval, minimizing downtime and improving operational efficiency.

Steel Coil Racking vs. Traditional Storage Methods

When it comes to storing steel coils, traditional storage methods such as stacking or using pallets may not be sufficient. Steel coils have specific handling requirements, and failure to meet these requirements can lead to damage, accidents, and inefficiencies.

A comparison of the advantages and disadvantages:

-

Advantages of Steel Coil Racking:

- – Maximizes space utilization and provides easy access to coils.

- – Ensures proper support and stability, reducing the risk of damage or accidents.

- – Improves efficiency, productivity, and inventory management.

- – Can accommodate various coil sizes and load capacities.

-

Disadvantages of Traditional Storage Methods:

- – Limited space utilization, resulting in wasted storage capacity.

- – Difficult to access individual coils, leading to longer retrieval times.

- – Increased risk of damage, deformation, or injuries due to unstable stacking.

- – Poor inventory management, making it challenging to track and organize coils effectively.

By investing in a steel coil racking system, you can overcome the limitations of traditional storage methods and optimize your warehouse storage solutions.

Factors to Consider when Choosing a Steel Coil Racking System

Selecting the right steel coil racking system is crucial for maximizing the efficiency and effectiveness of your warehouse storage operations. Here are some factors to consider when choosing a system:

-

Coil Dimensions and Weight: Determine the average size, weight, and types of steel coils you will be storing to ensure that the racking system can accommodate them effectively.

-

Storage Capacity: Evaluate your current and future storage needs to determine the required capacity of the racking system. Consider factors such as the number of coils, frequency of replenishment, and space availability.

-

Warehouse Layout and Space Constraints: Assess your warehouse layout and space constraints to determine the most suitable racking configuration. Consider factors such as aisle widths, ceiling height, and floor space.

-

Handling Equipment Compatibility: Ensure that the chosen racking system is compatible with your existing or planned handling equipment, such as forklifts or cranes, to ensure smooth and efficient operations.

-

Durability and Safety Features: Look for a racking system that is built to last and equipped with safety features such as locking mechanisms, non-slip surfaces, and load visibility indicators.

-

Ease of Installation and Adaptability: Consider the ease of installation and the flexibility of the racking system to accommodate future changes or expansion in your warehouse.

By carefully considering these factors, you can ensure that you select a steel coil racking system that meets your specific storage requirements and optimizes your warehouse operations.

How to Optimize Steel Coil Racking: Warehouse Design and Layout

Optimizing your steel coil racking system goes beyond selecting the right equipment. It also involves strategic warehouse design and layout considerations to maximize efficiency and productivity. Follow these best practices to optimize your racking system:

1. Assess your storage needs and requirements

Before designing your warehouse layout, assess your storage needs and requirements. Determine the number of coils you need to store, the frequency of replenishment, and any specific handling requirements. This information will help you determine the appropriate size and capacity of the racking system.

2. Determine the appropriate racking system for your steel coils

Based on your storage needs and coil dimensions, select the most suitable type of steel coil racking system. Also, consider factors such as load capacity, adjustability, and ease of access. Ensure that the chosen system can accommodate your current and projected inventory.

How to choose the right steel coil racking system:

- – Consider the size and weight of your steel coils.

- – Evaluate the storage capacity and adjustability of the system.

- – Check the compatibility with your handling equipment.

- – Assess the safety features and durability of the system.

3. Optimize your warehouse space for efficient steel coil storage

Design your warehouse layout in a way that maximizes space utilization and ensures smooth operations. Consider factors such as aisle widths, clearance heights, and the flow of goods. Finally, implement efficient material handling processes to minimize travel time and streamline operations.

Best practices for warehouse layout and organization:

- – Optimize aisle widths to allow easy movement of handling equipment.

- – Create clear pathways and designate specific areas for loading and unloading.

- – Utilize vertical space by implementing multi-level racking systems.

- – Implement efficient material flow processes to minimize travel time and increase productivity.

4. Implement safety precautions and regulations

Safety should always be a top priority in a warehouse environment. Therefore, implement safety precautions and regulations to protect your employees and prevent accidents. This includes providing proper training, using appropriate equipment, and enforcing safety guidelines.

Safety guidelines for steel coil racking:

- – Train employees on proper handling and safety procedures.

- – Ensure that handling equipment is in good working condition.

- – Regularly inspect the racking system for any signs of damage or instability.

- – Use safety features such as locking mechanisms and non-slip surfaces.

By optimizing your warehouse design and layout, you can ensure that your steel coil racking system operates at its full potential, maximizing efficiency and productivity while maintaining a safe work environment.

Conclusion

Optimizing your steel coil racking system is essential for maximizing your warehouse storage solutions. By understanding the benefits, types, and operation of steel coil racking systems, you can make informed decisions when selecting and implementing the right system for your needs.

Ensure the safety, productivity, and longevity of your steel coil racking system by following best practices in warehouse design, maintenance, quality control, and operational efficiency. By staying updated on industry standards, studying case studies, and accessing relevant tools and resources, you can continuously improve and optimize your steel coil racking system, driving success in your warehouse storage operations.