Explore innovative designs, practical applications, and the numerous benefits of utilizing a wine barrel rack for your facility.

Read MoreNesting Racks: Explore the Compact Brilliance

What are nesting racks?

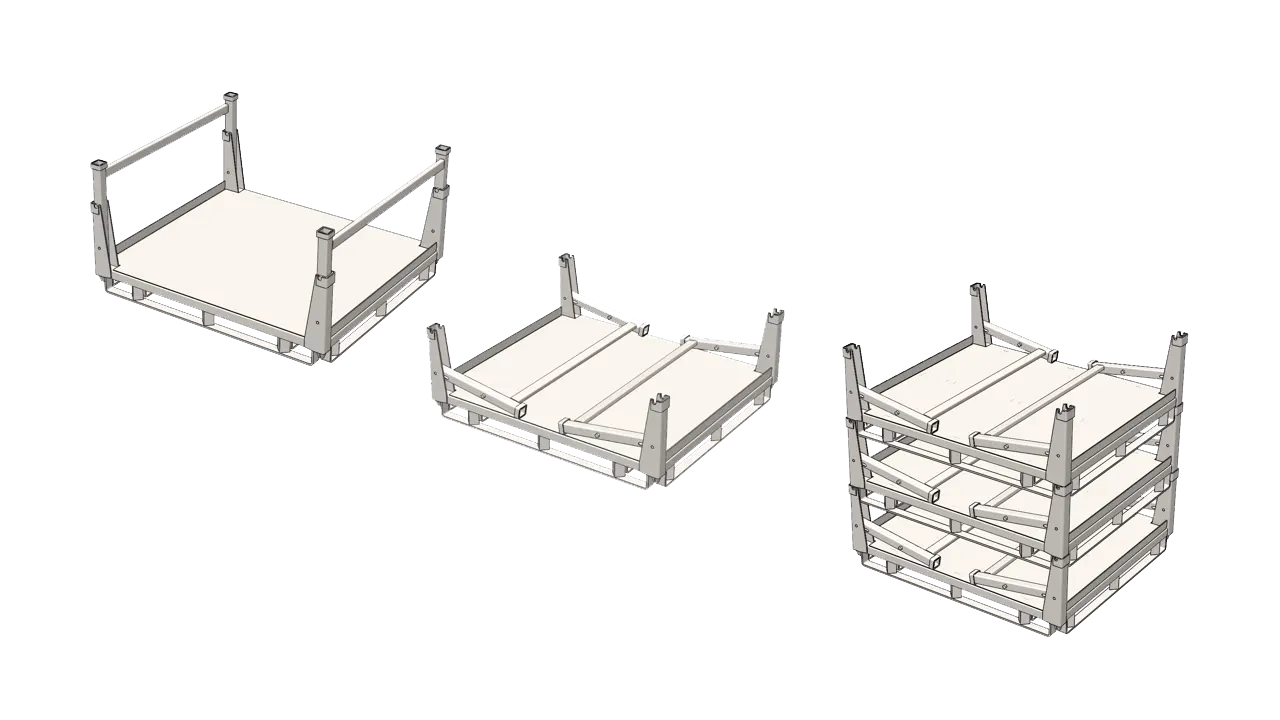

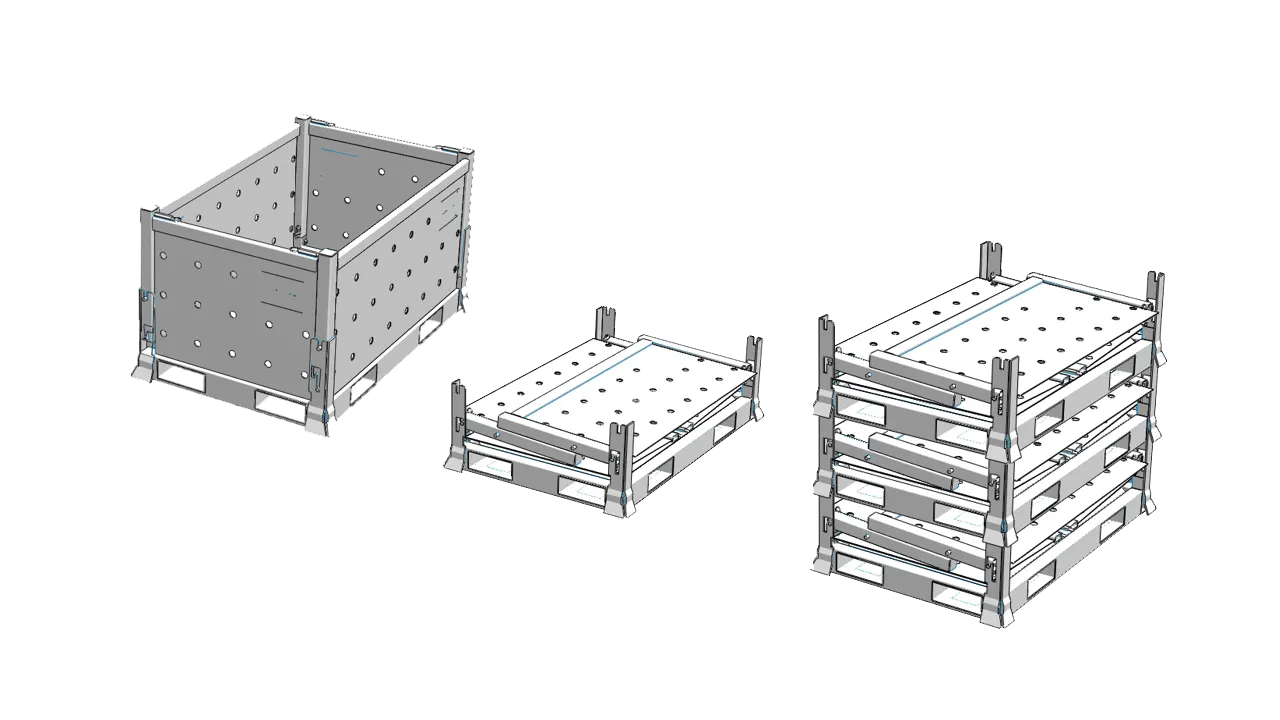

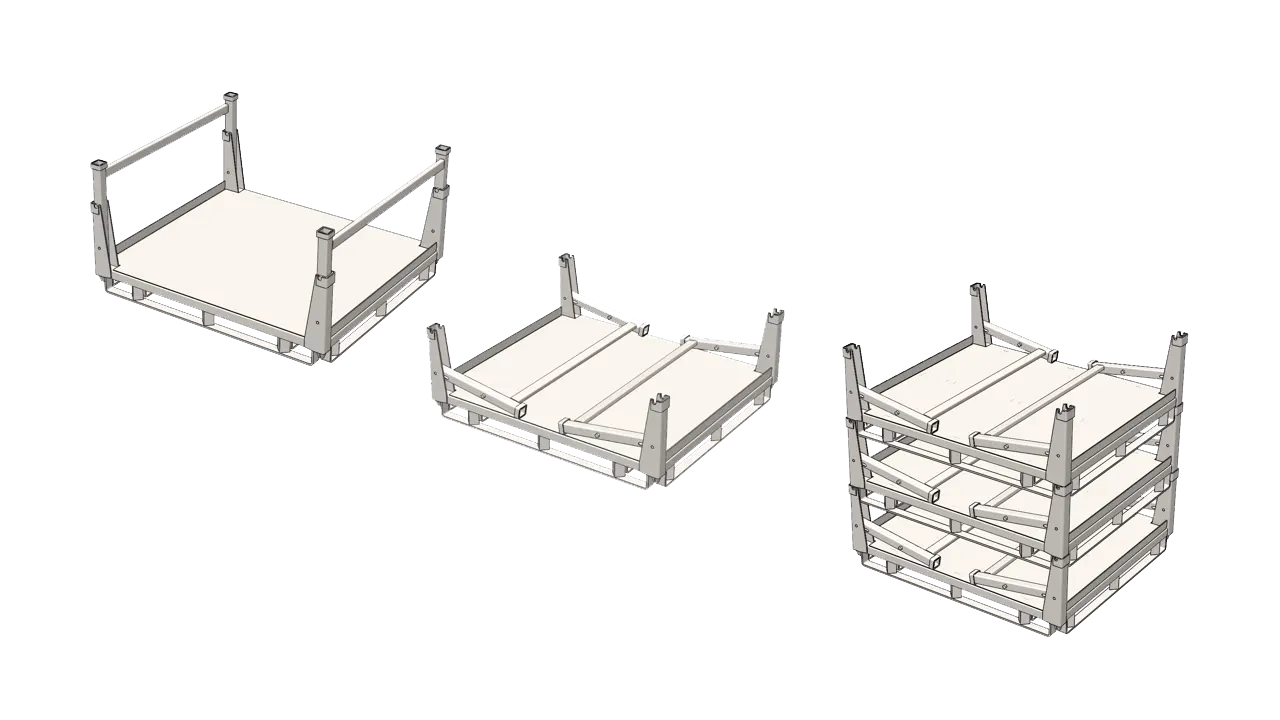

Nesting racks are a type of storage solution that are designed to maximize space efficiency. They are characterized by their ability to stack or nest within one another when not in use, creating a compact footprint that optimizes storage capacity. This design allows for easy storage, transportation, and stacking of the racks, making them ideal for warehouse and industrial environments.

When it comes to storage, space is a valuable commodity. Traditional storage solutions can often be bulky and take up a significant amount of space, limiting the storage capacity. However, these racks offer a solution to this problem. By nesting within each other when not in use, they can significantly reduce the amount of space required for storage. This nesting feature allows for a more efficient use of the available space and ensures that valuable warehouse real estate is used to its fullest potential.

There are several benefits to using nesting racks for storage. Firstly, they help to optimize space utilization, increasing the overall storage capacity of a warehouse or storage facility. This can lead to cost savings, as businesses can store more inventory without the need for additional space or expansion. Additionally, these racks are easy to stack and store, simplifying the process of organizing and accessing stored items. This leads to improved workflow and productivity, as well as reducing the risk of accidents or damage to stored items.

Why choose nesting racks for storage?

Introduction to nesting racks

Nesting racks are storage solutions that are designed to maximize space efficiency and optimize storage capacity. They are commonly used in industrial and warehouse environments where space is a valuable commodity. The main purpose of these racks is to provide a compact storage solution that can be easily stacked and nested when not in use, allowing for efficient use of available space.

How nesting racks optimize storage space

One of the primary advantages of these racks is their ability to optimize storage space. Traditional storage solutions often require a significant amount of floor space, limiting the overall storage capacity. However, these racks can significantly reduce this footprint by nesting within one another when not in use. This means that when empty, the racks can be stacked vertically, occupying a fraction of the space that would be required by traditional storage solutions.

Cost-saving advantages of nesting racks

By optimizing storage space, these racks can also lead to cost savings for businesses. With limited space, warehouse and storage facility expansion can be expensive, both in terms of construction costs and ongoing operational expenses. By using these racks, businesses can maximize their storage capacity without the need for additional space or expansion. This not only saves on construction costs but also reduces ongoing operational expenses such as heating, cooling, and maintenance.

Types of nesting racks

When it comes to nesting racks, there are several different types available, each with its own features and capabilities. Understanding the options available can help businesses choose the most suitable racks for their specific needs.

Exploring different types of nesting racks available in the market

- Stackable nesting racks: These racks are designed to stack one on top of another when not in use. They are typically made of durable materials such as steel or plastic and are commonly used in industrial and warehouse environments.

- Collapsible nesting racks: These racks have the ability to collapse and fold when not in use, resulting in a compact storage solution that takes up minimal space. They are often made of lightweight materials such as aluminum or plastic and are commonly used in industries that require frequent transportation or handling of goods.

- Roll containers: Roll containers are nesting racks that are equipped with casters, allowing for easy transportation and movement of goods. They are commonly used in retail and distribution environments where efficient handling and mobility of goods are required.

Understanding the features and capabilities of each type

- Stackable nesting racks: These racks are sturdy and durable, making them suitable for heavy-duty applications. They can be easily stacked and nested, allowing for efficient use of vertical space. The open design of these racks also allows for easy visibility and access to the stored items.

- Collapsible nesting racks: These racks are lightweight and easy to handle, making them ideal for applications that require frequent transportation or handling of goods. They can be quickly collapsed and folded, taking up minimal space when not in use. The collapsible design also allows for easy adjustment of the rack height, accommodating different sizes of items.

- Roll containers: These racks are equipped with casters, making them highly mobile and easy to transport. They are commonly used in retail and distribution environments where efficient movement of goods is essential. Roll containers often feature shelves or dividers, allowing for efficient organization of items.

Benefits of using nesting racks

The use of nesting racks offers several benefits for businesses looking to optimize their storage and improve operational efficiency. These benefits include:

Maximizing warehouse efficiency through nesting racks

Nesting racks are a key component in maximizing warehouse efficiency. By optimizing storage space and increasing storage capacity, businesses can store more inventory without the need for additional space. This leads to better organization, improved workflow, and increased productivity. Additionally, these racks simplify the process of accessing and locating stored items, reducing the time spent on warehouse operations.

Reducing storage footprint and increasing capacity

One of the primary advantages of these racks is their ability to reduce the storage footprint. By nesting within one another when not in use, these racks can significantly reduce the amount of space required for storage. This creates more space for other operations or allows businesses to store more inventory without the need for additional space. The increased storage capacity provided by these racks can lead to cost savings and improved efficiency.

Streamlining operations and improving productivity

Nesting racks streamline operations and contribute to improved productivity in several ways. Firstly, the compact design of these racks allows for easy stacking and nesting when not in use, simplifying the storage process. This saves time and effort during loading and unloading operations. Secondly, these racks improve organization and visibility of stored items, making it easier for employees to locate and access the required items. This leads to reduced downtime and improved efficiency in day-to-day operations.

Factors to consider when selecting nesting racks

When selecting nesting racks for a business, there are several factors to consider to ensure that the chosen racks meet the requirements and provide the desired benefits. These factors include:

Size and weight capacity requirements

Different businesses have different storage needs, and it is important to consider the size and weight capacity requirements when selecting nesting racks. The racks should be able to accommodate the size and weight of the items to be stored without compromising the structural integrity of the racks.

Material and durability considerations

The material and durability of these racks are crucial factors to consider. The racks should be made of high-quality materials that can withstand the demands of the application. Consider the nature of the items to be stored, the environmental conditions of the facility, and the expected lifespan of the racks when selecting the material and durability features.

Compatibility with existing equipment and infrastructure

It is also important to consider the compatibility of these racks with the existing equipment and infrastructure of the facility. Ensure that the racks can be easily integrated into the existing warehouse layout, and that they are compatible with the handling equipment and storage systems already in place. This will help to avoid any disruptions or additional costs associated with modifying the infrastructure.

How to use nesting racks effectively

Using nesting racks effectively involves implementing proper organization and categorization strategies, efficient loading and unloading techniques, and regular maintenance and care.

Proper organization and categorization strategies

To use these racks effectively, it is important to implement proper organization and categorization strategies. This involves assigning specific areas or sections of the racks for different types or categories of items. Implementing a labeling system can also help to improve visibility and accessibility of the stored items. Regular maintenance, such as cleaning and inspecting the racks, ensures that they remain in good condition and are ready for use.

Efficient loading and unloading techniques

Efficient loading and unloading techniques are essential for maximizing the use of nesting racks. This includes proper stacking and nesting of the racks to optimize space utilization, as well as ensuring that the weight distribution is balanced to maintain stability. Providing training to employees on proper handling and loading techniques can help to minimize the risk of accidents or damage to the racks and stored items.

Maintenance and care tips for nesting racks

Regular maintenance and care are important to ensure the longevity and durability of these racks. This includes cleaning the racks regularly to remove any debris or contaminants that may affect their performance or structural integrity. Regular inspections should also be conducted to identify any signs of damage or wear and tear. Repairs or replacements should be made as necessary to ensure the racks remain in good condition and are safe to use.

Key features to look for in nesting racks

When selecting nesting racks, there are several key features to look for to ensure that they meet the specific needs and requirements of a business. These features include:

- Durability: The racks should be made of high-quality materials that can withstand the demands of the application. This ensures that the racks can withstand heavy loads and rough handling without compromising their structural integrity.

- Versatility: Look for nesting racks that offer versatility in terms of adjustability and customization. This allows for easy adaptation to different types and sizes of items, maximizing the storage capacity.

- Safety features: These racks should be equipped with safety features such as locking mechanisms or stabilizing devices to ensure stability and prevent accidents or damage to the stored items.

- Ease of use: Look for nesting racks that are easy to handle and operate. Features such as ergonomic handles or wheels can enhance the ease of use and improve overall efficiency.

- Compatibility: Consider the compatibility of these racks with existing equipment and infrastructure. This includes ensuring that the racks can be easily integrated into the existing warehouse layout and that they are compatible with the handling equipment and storage systems already in place.

Best practices for storing items in nesting racks

To optimize storage efficiency with nesting racks, it is important to follow certain best practices. These practices include:

- Proper item categorization: Categorize items based on size, weight, and usage frequency to ensure efficient organization within the nesting racks. This makes it easier to locate and access the required items when needed.

- Proper weight distribution: Ensure that the weight is distributed evenly when stacking and nesting the racks to maintain stability and prevent accidents or damage.

- Secure stacking: Stack the these racks securely, ensuring that they are stable and do not pose a safety hazard. This can be achieved by using stabilizing devices or locking mechanisms provided by the racks.

- Regular maintenance and inspections: Regularly clean and inspect the these racks to identify any signs of damage or wear and tear. This allows for timely repairs or replacements, ensuring that the racks remain in good condition and are safe to use.

Nesting racks vs. alternative storage solutions

When it comes to storage, there are several alternative solutions available, each with its own advantages and disadvantages. Comparing nesting racks with other popular storage options can help businesses determine the most suitable solution for their specific needs.

A comparison of nesting racks with other popular storage options

- Pallet racking: Pallet racking is a common storage solution that allows for easy accessibility and handling of palletized goods. However, pallet racking can be bulky and may require a significant amount of floor space. Nesting racks, on the other hand, offer a more space-efficient solution by nesting within each other when not in use.

- Shelving units: Shelving units provide easy access to stored items but may not be as space-efficient as nesting racks. Shelving units often require dedicated floor space and may not offer as much flexibility in terms of stacking or nesting.

- Wire mesh containers: Wire mesh containers are durable and provide good visibility of stored items. However, they may not be as space-efficient as nesting racks, as they do not have the nesting feature that allows for compact storage.

Identifying the advantages and disadvantages of each solution

- Nesting racks:

Advantages-> space efficiency, easy stacking and nesting, and improved visibility and access.

Disadvantages -> limited weight capacity and limited compatibility with certain types of items. - Pallet racking:

Advantages-> easy accessibility and handling of palletized goods and high weight capacity.

Disadvantages -> a larger storage footprint and limited flexibility in terms of nesting or stacking. - Shelving units:

Advantages-> easy access to stored items and flexibility in terms of customization.

Disadvantages -> limited space efficiency and lower weight capacity compared to nesting racks. - Wire mesh containers:

Advantages-> durability and good visibility of stored items.

Disadvantages -> limited space efficiency compared to nesting racks and limited flexibility in terms of stacking or nesting.

Summary

Nesting racks are an efficient storage solution that can help businesses optimize their storage capacity and improve operational efficiency. By understanding the concept of these racks, exploring the different types available, and considering key factors when selecting nesting racks, businesses can make informed decisions and choose the most suitable solution for their specific needs.

Implementing proper organization and categorization strategies, efficient loading and unloading techniques, and regular maintenance and care can help businesses use these racks effectively and maximize their benefits. Comparing these racks with alternative storage solutions allows businesses to identify the advantages and disadvantages of each option and choose the most suitable solution for their specific needs. With the right nesting racks in place, businesses can streamline their storage operations, maximize their storage capacity, and improve overall efficiency.

Customize Your Own & Get a FREE Estimate!

Simply e-mail us at sales@plexformps.com with all your information

OR call us today & speak to one of our packaging professionals