Explore cutting-edge designs, practical applications, and the numerous benefits of advanced automotive racking systems.

Read MoreMold Storage Rack: Elevate Your Workflow

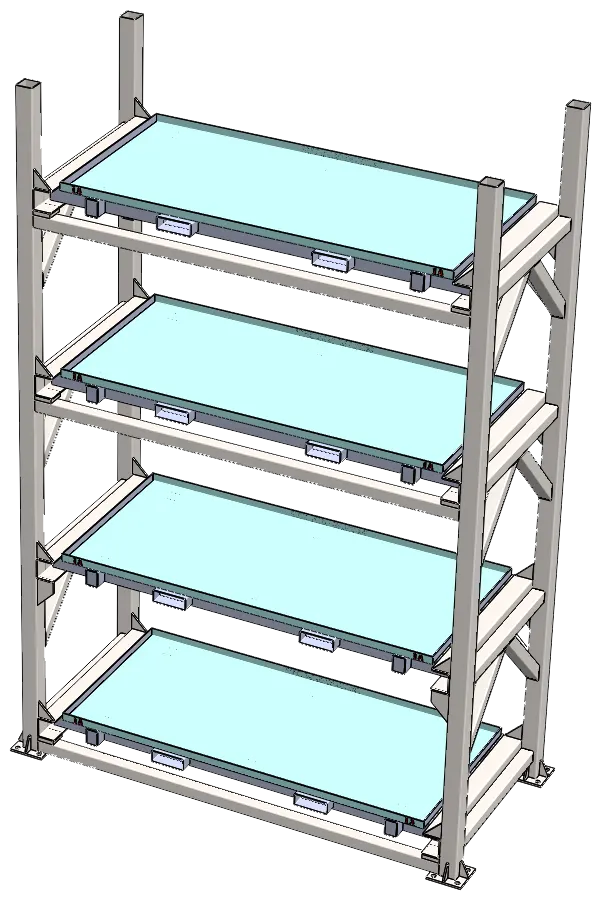

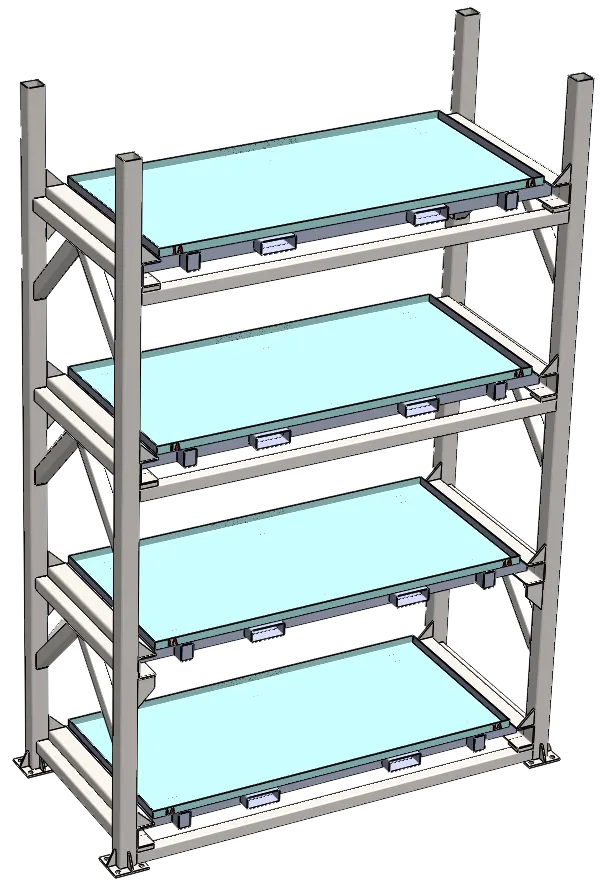

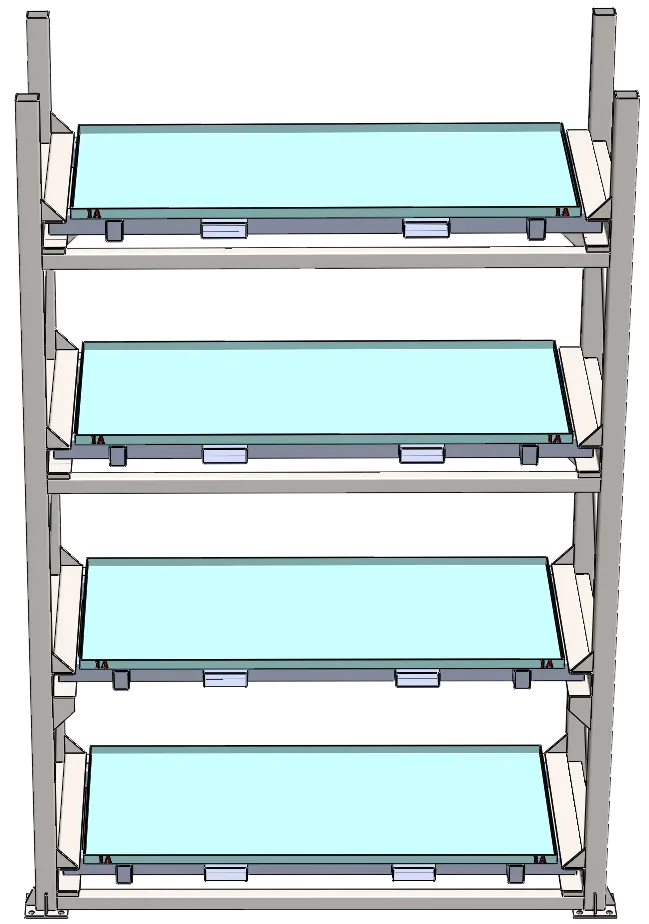

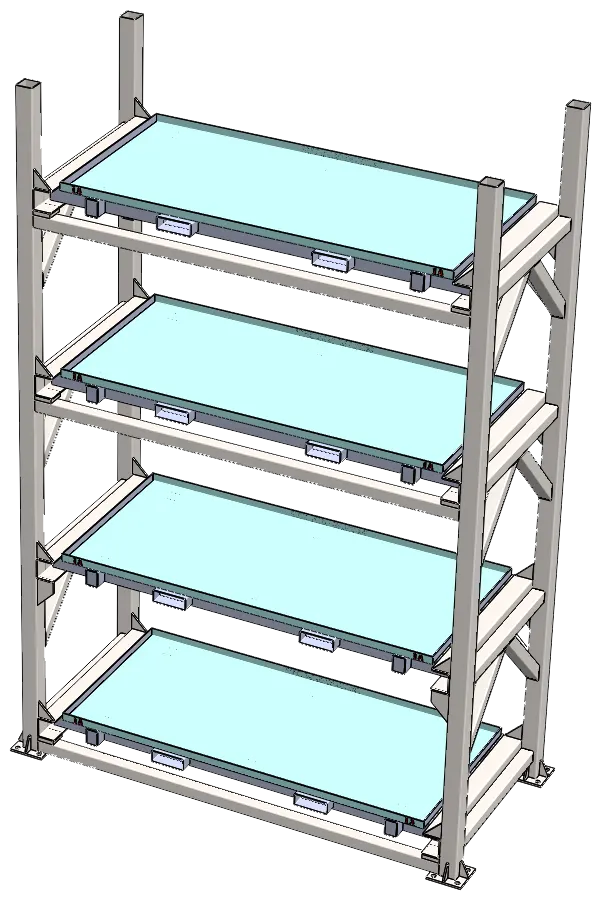

What is a mold storage rack?

A mold storage rack is a specialized storage system designed to efficiently store and organize molds used in manufacturing processes. Molds are critical tools used in various industries, including automotive, aerospace, consumer goods, and more. Essentially, they are used to create complex shapes and patterns in materials such as plastic, metal, or rubber. However, molds can be large, heavy, and delicate, requiring a dedicated storage solution to ensure their safety and accessibility.

Importance of a mold storage rack

Efficient storage of molds is crucial for several reasons. First, molds can be expensive and delicate, making it essential to protect them from damage. Storing them randomly or in inappropriate conditions can lead to mold distortion, breakage, or contamination, resulting in costly replacements or production delays. Second, molds can take up significant space in manufacturing facilities, and without proper organization, they can create clutter and safety hazards. Finally, a well-planned mold storage rack allows for easier mold retrieval and reduces downtime during production changeovers.

Types of mold storage racks

There are various types of mold storage racks available to accommodate different needs and spaces. The most common types include:

-

Vertical storage racks: These racks are designed to store molds vertically, allowing for efficient use of vertical space. In fact, they are ideal for facilities with limited floor space.

-

Horizontal storage racks: These racks are designed to store molds horizontally, offering quick and easy access to each mold. Above all, they are suitable for larger molds that cannot be stored vertically.

-

Rotating storage racks: These racks consist of rotating shelves, allowing for easy access to multiple molds without the need for manual repositioning. In particular, they are best utilized for facilities where space optimization and quick retrieval are essential.

Factors to consider when choosing a mold storage rack

When choosing a mold storage rack, there are several factors to consider:

- Size and weight capacity: Ensure that the rack can accommodate the size and weight of your molds.

- Accessibility: Select a rack that facilitates effortless access to molds, minimizing the necessity for excessive lifting or repositioning.

- Space utilization: Consider the limited floor space, and select a rack that maximizes storage capacity.

- Durability: Choose a robust and reliable rack capable of withstanding the molds’ weight and environment..

- Flexibility: Assess the rack’s flexibility and compatibility to various mold sizes and shapes.

Benefits of using a mold storage rack

Utilizing a mold storage rack offers several benefits:

-

Improved organization: By having a dedicated storage solution for molds, you can keep them organized and easily accessible, reducing the risk of damage or loss.

-

Optimized space: Mold storage racks are designed to efficiently utilize vertical space, allowing you to maximize your storage capacity without expanding the floor area.

-

Time-saving: By maintaining an orderly rack, one can efficiently locate and retrieve the necessary molds, thereby reducing delay during production and enhancing overall efficiency.

-

Enhanced safety: Mold storage racks provide a safe and secure storage environment, protecting molds from potential damage caused by mishandling, collisions, or contaminants.

-

Cost savings: By minimizing the risk of injury and storing molds appropriately, it is possible to prevent expensive mold replacements and maintain consistent production schedules.

How to choose the right mold storage rack for your needs

To choose the right mold storage rack for your needs, follow these steps:

-

Evaluate your mold inventory: Determine the types, sizes, and weights of the molds you need to store.

-

Assess your space: Measure your available floor space and take into account any height limitations.

-

Consider accessibility: Based on the size of the mold and the workflow, choose whether vertical or horizontal storage racks would best suit your needs.

-

Determine capacity requirements: Determine the quantity of molds that require storage and verify that the selected rack has the capacity to hold the inventory.

-

Research different rack options: When comparing various manufacturers and models, it is important to take into account consumer reviews, adjustability, and build quality.

-

Review additional features: Consider additional features that could assist your individual use case, such as locking mechanisms, anti-vibration features, or configurable setups.

-

Get professional advice: Consult with storage solution experts who can provide guidance and recommendations based on your specific requirements.

-

Make a well-informed decision: Select the mold storage rack that best aligns with your needs, budget, and available space.

How to maximize space with a mold storage rack

To maximize space utilization with a mold storage rack, consider implementing the following strategies:

-

Utilize vertical space: Select a vertical storage rack design to maximize the amount of height that is available while enabling molds to be stored upright.

-

Customize rack configurations: Choose a mold storage rack that offers adjustable shelves or partitions, enabling you to customize the rack’s layout to accommodate different mold sizes and shapes.

-

Consolidate molds: Group smaller molds together and store them in designated compartments or drawers to reduce wasted space and improve accessibility.

-

Consider mobile racks: If you need flexibility in rearranging your storage layout, consider mobile mold storage racks that can be easily moved to create additional space when needed.

-

Implement compact storage options: Examine space-saving storage solutions that enable the storage of several molds in a smaller footprint, such as rotating racks or sliding shelves.

Common challenges and solutions when using a mold storage rack

While mold storage racks offer numerous benefits, there are some common challenges to be aware of:

-

Limited space: In order to enhance storage capacity without increasing the floor area, take into consideration vertical storage racks or compact design solutions if your facility has limited space.

-

Mold size and weight: Ensure the rack you choose can accommodate the size and weight of your molds. Consult the rack manufacturer or a storage solution professional to discover the proper weight capacity and design criteria.

-

Specialized mold requirements: Certain molds could need certain storage circumstances, such humidity or temperature regulation. To satisfy these needs, take into consideration specialized racks or insulating options.

-

Frequent mold changes: If your production involves frequent mold changes, consider mobile mold storage racks that can be easily repositioned to maximize efficiency and workflow.

Mold storage rack safety measures

To ensure the safety of both molds and personnel, observe the following safety measures:

-

Proper lifting techniques: Train employees on proper lifting techniques to minimize the risk of personal injury and prevent damage to the molds.

-

Load distribution: To keep the rack stable and avoid overloading individual shelves, ensure that the weight of the molds is evenly distributed.

-

Secure storage: Implement locking mechanisms or other security elements to prevent unauthorized access to molds, reducing the risk of theft or damage.

-

Establish safety protocols: Develop and enforce safe procedures for mold storage, retrieval, and maintenance. This involves wearing proper personal protection equipment and following established procedures.

-

Regular inspections: Conduct monthly inspections of the mold storage rack to look for any potential safety issues, such as loose bolts, damaged shelves, or unstable structure. Address these issues promptly to maintain a safe working environment.

Conclusion

In summary, a mold storage rack is an essential storage solution for efficiently organizing and protecting molds used in various manufacturing processes. By investing in a suitable rack and implementing proper organizing techniques and maintenance practices, manufacturers can ensure the safety, accessibility, and longevity of their molds.

Consider the specific needs of your molds, available space, and workflow requirements when choosing a mold storage rack to maximize its benefits. Proper utilization and maintenance of mold storage racks are essential for optimizing production efficiency, minimizing downtime, and reducing costs associated with mold damage or replacement.

Customize Your Own & Get a FREE Estimate!

Simply e-mail us at sales@plexformps.com with all your information

OR call us today & speak to one of our packaging professionals