Explore innovative designs, practical applications, and the numerous benefits of utilizing a wine barrel rack for your facility.

Read MoreMetal Pallets with Sides: Maximize Part Protection

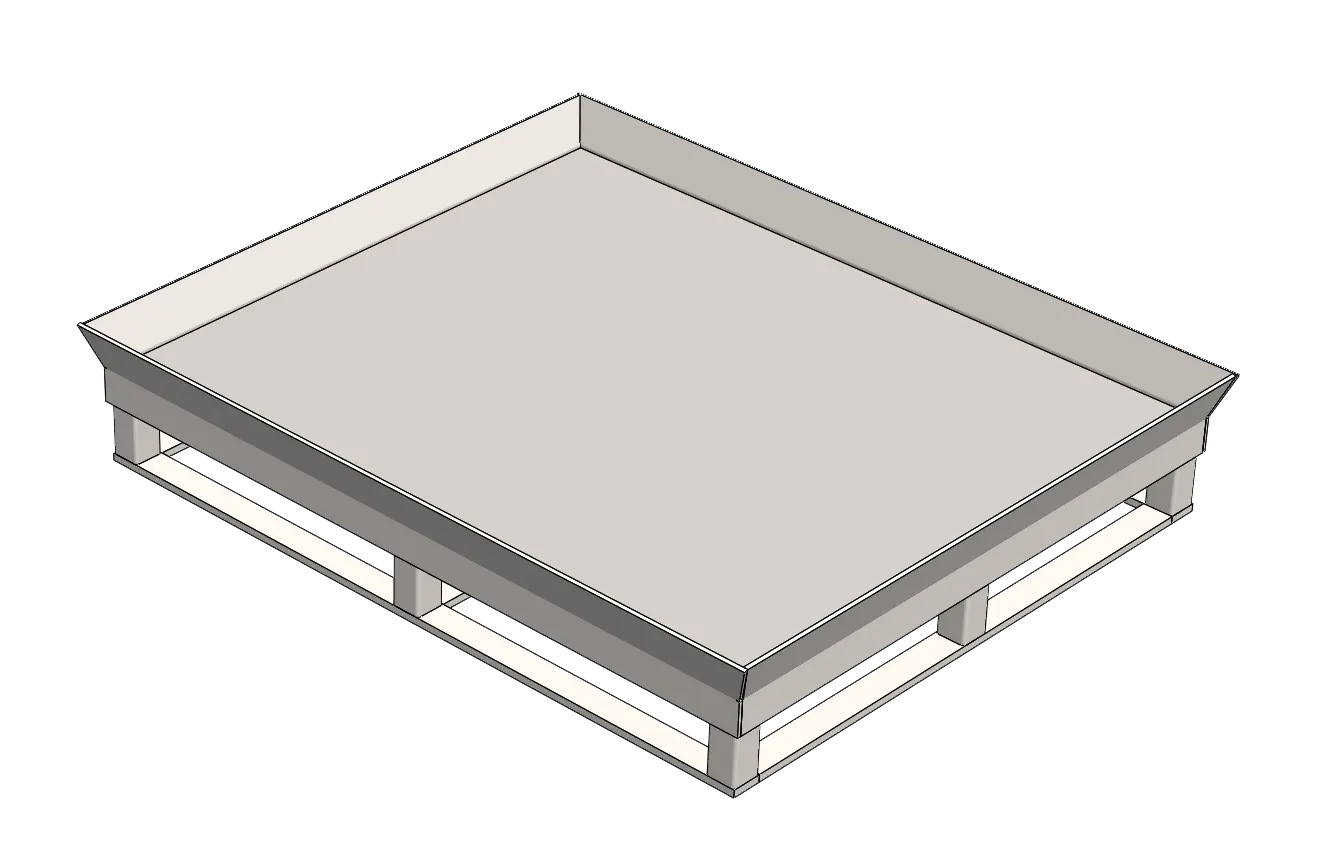

What are Metal Pallets with Sides?

Metal pallets with sides are a type of pallet that are primarily made of metal and feature enclosed sides. These pallets are used to transport and store goods in various industries such as manufacturing, warehousing, and logistics. Furthermore, the sides of the pallet provide additional stability and security for the goods being transported, preventing them from falling off or getting damaged.

Key Takeaways:

- -> Metal pallets with sides are made of metal and have enclosed sides.

- -> They provide enhanced stability and security for goods during transportation and storage.

- -> These pallets are commonly used in manufacturing, warehousing, and logistics industries.

Introduction to Metal Pallets with Sides

Metal pallets with sides are a versatile and reliable solution for businesses that require efficient and secure transportation and storage of goods. These pallets offer several advantages over traditional pallets, making them a popular choice in various industries.

A formal definition of Metal Pallets with Sides:

These enclosed metal pallets are flat structures with built-in sides made of metal materials. These sides typically consist of metal bars or mesh panels, providing a protective enclosure for the goods being transported or stored. Above all, the sides offer a secure barrier that prevents items from falling off or shifting during handling or transportation.

How are Metal Pallets with Sides different from traditional pallets?

Traditional pallets are typically made of wood or plastic and do not have enclosed sides. While they are suitable for many applications, they lack the added security and stability provided by these metal pallets. Also, the sides of metal pallets act as a protective barrier, preventing goods from toppling over or being damaged during loading, unloading, and transportation.

The benefits and advantages of Metal Pallets with Sides:

Metal pallets with sides offer numerous benefits to businesses in terms of efficiency, safety, and cost-effectiveness. Some of the key advantages of using pallets include:

-

Enhanced Security: The enclosed sides of metal pallets provide a secure environment for goods, preventing them from falling off or getting damaged.

-

Increased Stability: The sturdy construction of metal pallets provides excellent stability, ensuring that the goods remain intact and balanced during transportation and storage.

-

Durability: Metal pallets are highly durable and can withstand heavy loads and harsh environments, making them ideal for long-term use.

-

Hygienic: These pallets are easy to clean and maintain, making them suitable for industries such as food processing and pharmaceuticals that require strict hygiene standards.

-

Environmental Sustainability: Metal pallets are reusable, recyclable, and have a longer lifespan compared to wooden or plastic pallets. Therefore, this makes them an eco-friendly option for businesses looking to reduce their environmental impact.

By opting for this pallet style, businesses can optimize their logistics operations, reduce the risk of damage to goods, and improve overall efficiency and profitability.

In the next sections, we will explore the importance, uses, and various factors to consider when choosing metal pallets with sides, as well as how to optimize your website for better visibility in search engines.

Importance and Uses of Metal Pallets with Sides

Metal pallets with sides play a crucial role in the transportation and storage of goods across various industries. Their importance stems from the unique features they offer, including enhanced security, stability, and durability. Here are some key uses of these pallets:

1. Safe Transportation of Fragile Goods

- Metal pallets with sides provide a secure enclosure that prevents fragile goods from being damaged or broken during handling and transportation. The sides act as a protective barrier, reducing the risk of items falling off or shifting.

2. Secure Storage in Warehouses

- These pallets are commonly used in warehouses to stack and store goods safely. Again, the sides prevent the items from toppling over, ensuring efficient use of storage space and minimizing the risk of accidents.

3. Handling Hazardous Materials

- For industries that deal with hazardous materials, metal pallets with sides are essential. The enclosed sides offer an added layer of protection, reducing the risk of spills or leaks during transportation.

4. Suitable for Automated Systems

- This pallet style is compatible with automated storage and retrieval systems, making them ideal for businesses that rely on robotic handling equipment. The sides help guide the automated machinery, ensuring smooth and efficient operation.

5. Improved Load Stability

- The enclosed sides feature is particularly beneficial when transporting tall or irregularly shaped items, as they will improve load stability

By utilizing metal pallets with sides, businesses can ensure safe and secure transportation, maximize storage space, and streamline their logistics operations.

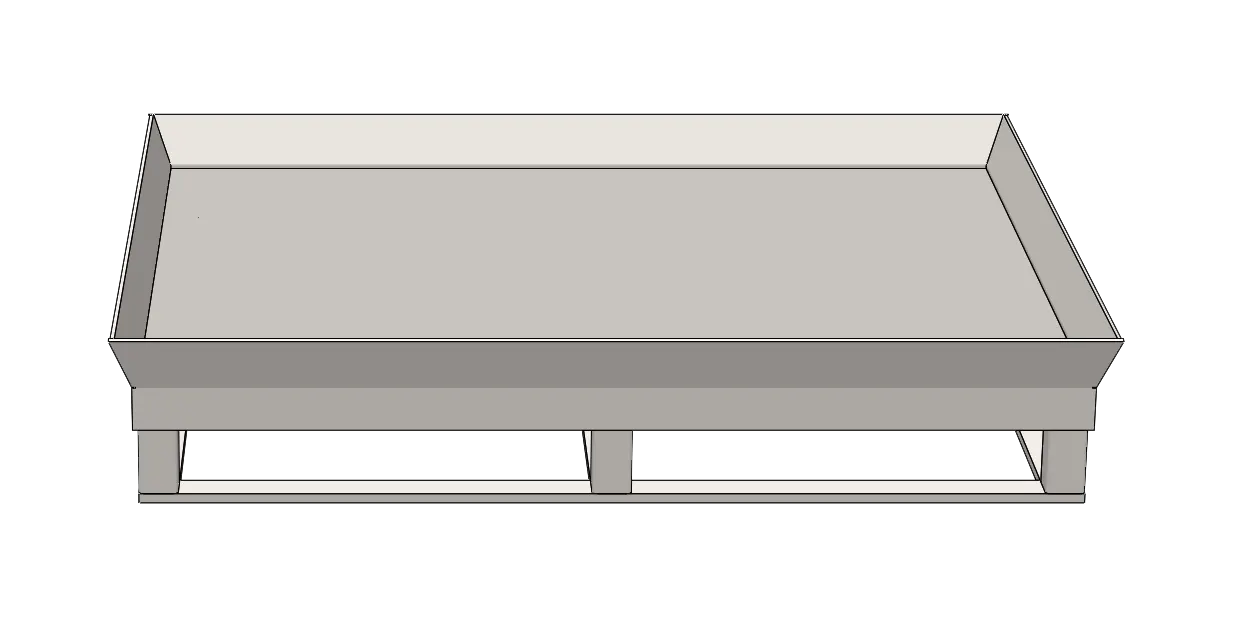

How do Metal Pallets with Sides work?

These pallets function as a sturdy and secure platform for the transportation and storage of goods. Due to the construction and design of these pallets, they allow for efficient handling, improved load stability, and enhanced security. Here’s how these pallets work:

1. Load Placement and Securing

- Goods are placed on top of the metal pallet, which provides a level and stable surface for stacking and securing the load.

2. Load Distribution

- Metal pallets with sides distribute the weight of the load evenly across their surface. As a result, this helps to maintain load stability and prevents damage to the goods.

3. Compatibility with Material Handling Equipment

- These pallets are designed to be compatible with various material handling equipment, such as forklifts and pallet jacks. Since the pallets have openings or slots at the bottom, this enables the forks or blades of the equipment to easily lift and move the pallet.

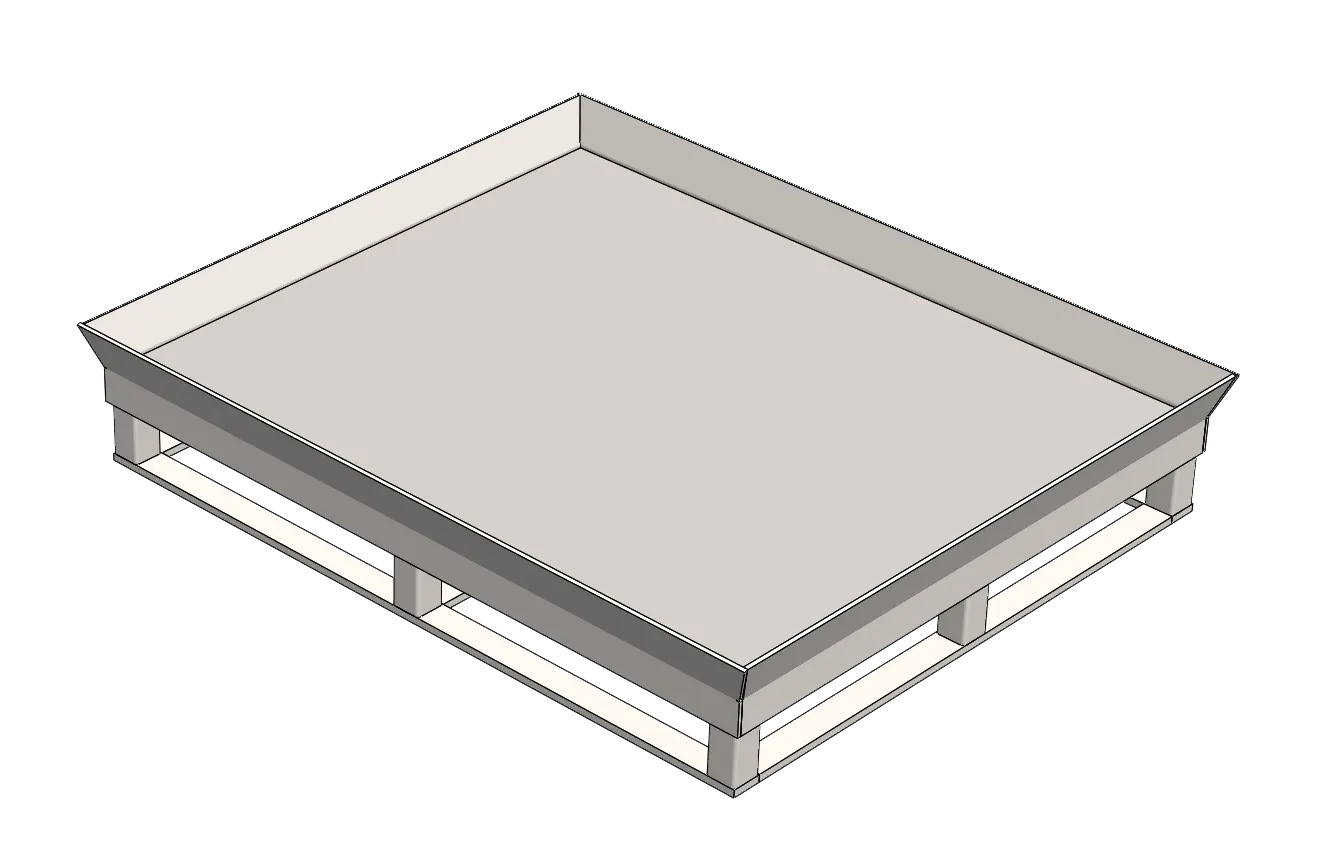

4. Nesting and Stacking

- Metal pallets with sides are designed to be stackable, allowing for efficient use of storage space. The sides of the pallets provide additional support when they are stacked on top of each other, ensuring stability and reducing the risk of collapse.

5. Securement Options

- These pallets offer various options for load securement. This may include strapping, wrapping, or using specialized load securing devices. The sides of the pallets act as anchor points for securing the load, preventing shifting or toppling during transportation.

The design and functionality of these pallets are optimized to ensure the safe and efficient transport and storage of goods. In fact, these pallets provide a stable and secure platform that minimizes the risk of damage or accidents, making them an essential tool in modern supply chain management.

In the next section, we will discuss the factors to consider when choosing metal pallets with sides and the safety measures and guidelines for their usage.

Factors to Consider when Choosing Metal Pallets with Sides

When choosing these pallets for your business, it’s crucial to consider various factors to ensure that you select the most suitable option. These factors will depend on the specific requirements of your industry, the nature of the goods being transported or stored, and the overall logistics operations. Here are some factors to consider:

1. Load Capacity and Weight Distribution

- Determine the expected load capacity of the metal pallets. Consider both the maximum weight the pallet can hold and the weight distribution requirements of your goods. Ensure that the pallets you choose can handle the weight and distribution requirements without compromising stability or safety.

2. Material Handling Equipment Compatibility

- Assess the compatibility of the metal pallets with the material handling equipment used in your operations. Ensure that the pallets can be easily lifted and moved by forklifts, pallet jacks, or any other equipment that you use. Also, check for compatibility with the equipment’s fork or blade dimensions, entry points, and lifting capacity.

3. Size and Dimensions

- Consider the size and dimensions of the metal pallets. Optimize storage space and transportation efficiency by choosing pallets that fit well within your storage facilities and vehicles. To ensure compatibility with existing systems and processes, please consider the standard dimensions used in your industry.

4. Durability and Maintenance

- Evaluate the durability of the metal pallets and their resistance to corrosion, impact, and other potential damages. Select pallets that can withstand the demands of your industry and are suitable for the environments in which they will be used. Also, consider the maintenance requirements and ensure that the pallets are easy to clean and repair if necessary.

5. Compliance with Industry Regulations and Standards

- Check if the metal pallets comply with any industry regulations or standards that are applicable to your operations. This may include regulations related to weight restrictions, load securing, hygiene, or international shipping requirements. In essence, ensure that the pallets meet the necessary standards to avoid any compliance issues.

6. Cost-effectiveness

- Assess the overall cost-effectiveness of the metal pallets. Consider factors such as the initial investment, lifespan, maintenance costs, and potential savings in logistics operations. That being said, choose pallets that offer a balance between quality, durability, and affordability.

Carefully considering these factors will help you select the most suitable metal pallets with sides for your specific needs, ensuring efficient operations and the safe transportation and storage of goods.

In the next section, we will discuss how to select the right size and weight capacity for metal pallets, as well as their impact on warehouse management.

How to Select the Right Size and Weight Capacity for Metal Pallets with Sides

Choosing the right size and weight capacity for these pallets is crucial to ensure that they can effectively accommodate your goods and meet your operational requirements. Here are some steps to help you select the appropriate size and weight capacity:

1. Determine your Product Requirements

- Assess the size, weight, and dimensions of the goods you typically transport or store on pallets. Consider whether your goods have any unique characteristics or special handling requirements that may impact the size and weight capacity of the pallets.

2. Understand Load Distribution

- Calculate the load distribution requirements for your goods. Consider factors such as weight distribution, load concentration points, and the type of material handling equipment used to move the pallets.

3. Evaluate Material Handling Equipment Capability

- Identify the specific material handling equipment you use, such as forklifts or pallet jacks. Understand their load capacity, fork or blade dimensions, and required entry points. Furthermore, ensure that these pallets can be easily lifted and moved by your equipment.

4. Consider Industry Standards

- Check if there are any industry standards or guidelines related to pallet sizes and weight capacities that are applicable to your operations. Adhering to these standards can ensure compatibility with other supply chain partners and systems.

5. Optimize Storage Space

- Analyze your storage space and facilities to determine the maximum pallet size that can be accommodated efficiently. Consider factors such as aisle widths, racking systems, and any height or space restrictions.

By considering these steps and factors, you can select the right size and weight capacity for pallets that best suit your business requirements and optimize your logistics operations.

Next, we will explore the impact of these pallets on warehouse management and their environmental benefits.

Metal Pallets with Sides and their Impact on Warehouse Management

The use of these palltes can have a significant impact on warehouse management, improving efficiency, safety, and overall productivity. Here are some ways metal pallets with sides can positively impact warehouse management:

1. Enhanced Load Stability

- These pallets provide improved load stability, preventing goods from shifting or toppling over during storage or transportation. This reduces the risk of accidents, minimizing product damage and ensuring safe working environments for warehouse personnel.

2. Efficient Space Utilization

- The sides of metal pallets allow for efficient utilization of vertical space within the warehouse. By stacking the pallets securely, businesses can maximize storage capacity, optimizing space utilization and reducing the need for additional warehouse infrastructure.

3. Streamlined Material Handling

- These pallets are designed to be compatible with material handling equipment such as forklifts, pallet jacks, and automated systems. This compatibility allows for streamlined and efficient material handling processes, reducing manual labor and improving overall operational efficiency.

4. Improved Warehouse Organization

- The use of metal pallets with sides can contribute to better warehouse organization and inventory management. By keeping products securely contained within the pallets, businesses can minimize the risk of misplaced or lost items.

5. Safety and Regulatory Compliance

- These pallets help businesses comply with safety regulations and industry standards related to storage and material handling. The added security and stability offered by the enclosed sides contribute to a safer working environment, reducing the risk of accidents or injuries.

Implementing metal pallets with sides in warehouse management processes can optimize space utilization, improve safety, and enhance overall productivity. The use of these pallets contributes to efficient logistics operations, creating a competitive advantage for businesses.

In the following section, we will explore into the environmental benefits of metal pallets with sides.

Environmental Benefits of Metal Pallets with Sides

These metal pallets offer several significant environmental benefits compared to wooden or plastic pallets. Ultimately, these benefits will contribute to sustainability and reduce the environmental impact of logistics operations. Here are some environmental advantages of using these pallets:

1. Reusability and Long Lifespan

- Metal pallets have a longer lifespan compared to wooden or plastic pallets. They can be reused multiple times, reducing the need for continuous replacement and reducing waste generation. As a result, this reusability feature will help reduce the consumption of natural resources.

2. Recyclability

- Metal pallets are highly recyclable at the end of their lifespan. The metal can be melted down and repurposed to create new metal products, reducing the demand for virgin resources. Consequently, this recycling process contributes to the circular economy and helps conserve natural resources.

3. Reduced Waste Generation

- The durability and longevity of these metal pallets result in reduced waste generation. Business operations that rely on metal pallets produce less waste compared to those using disposable or single-use pallets, ultimately minimizing their environmental footprint.

4. Lower Carbon Emissions

- Metal pallets with sides have a lower carbon footprint than wooden or plastic pallets. The manufacturing process for metal pallets emits fewer greenhouse gases, contributing to reduced carbon emissions. Additionally, the ability to reuse and recycle metal pallets reduces the need for energy-intensive manufacturing processes.

5. Waste Management Efficiency

- These pallets eliminate the need for disposal and waste management associated with wooden or plastic pallets. With metal pallets, there is no need to process or dispose of damaged or broken pallets, reducing waste management costs and the environmental impact associated with pallet disposal.

6. Elimination of Chemical Treatments

- Unlike wooden pallets that often require chemical treatments to prevent pests, rot, or mold, metal pallets do not require any chemical treatments. This eliminates the use of harmful chemicals, reducing environmental pollution and potential health risks.

The environmental benefits of using metal pallets make them an eco-friendly choice for businesses aiming to reduce their environmental impact and promote sustainability. By implementing these pallets in their operations, businesses can align with their corporate social responsibility goals and contribute to a greener future.

Summary

Metal pallets with sides are an indispensable asset for businesses operating in various industries, providing enhanced stability, security, and efficiency in the transportation and storage of goods. Their robust construction, coupled with the added level of protection offered by the enclosed sides, make them an ideal choice for businesses seeking to optimize their supply chain operations.

Customize Your Own & Get a FREE Estimate!

Simply e-mail us at sales@plexformps.com with all your information

OR call us today & speak to one of our packaging professionals