Explore innovative designs, practical applications, and the numerous benefits of utilizing a wine barrel rack for your facility.

Read MoreMaterial Handling Carts: Navigate Workflow & Maximize Production

What are Material Handling Carts?

Material handling carts are essential equipment used in various industries to efficiently move and transport materials within a facility. They are designed to simplify the process of transporting heavy or bulky items, making it easier for employees to move materials from one point to another. These carts come in a variety of designs and configurations, allowing businesses to choose the one that best suits their specific needs.

The Importance of Material Handling Carts

Material handling carts play a crucial role in streamlining operations and improving overall efficiency in industries such as manufacturing, warehousing, and healthcare. They offer several benefits that contribute to a more efficient and productive work environment.

Benefits of using material handling carts include:

-

Increased Productivity: Material handling carts eliminate the need for manual carrying or lifting of heavy items, reducing strain on employees and enabling them to move materials more quickly and easily.

-

Streamlined Operations: These carts facilitate the smooth flow of materials from one workstation to another, eliminating bottlenecks and reducing unnecessary downtime.

-

Improved Workplace Safety: These carts are designed with safety features such as sturdy handles, non-slip surfaces, and locking mechanisms to ensure the safe transportation of materials and reduce the risk of accidents.

-

Enhanced Ergonomics: Ergonomic design features, such as adjustable heights and cushioned handles, help reduce stress on employees’ bodies, resulting in fewer injuries and increased comfort during transport.

The role of material handling carts in streamlining operations:

These carts are essential tools in optimizing the movement of materials within a facility. By providing a reliable and efficient means of transporting materials, they contribute to streamlining operations, reducing manual labor, and eliminating unnecessary steps in the process. This ultimately leads to increased productivity and cost savings for businesses.

Types of Material Handling Carts

These carts come in various types and designs to meet different material transportation requirements. By categorizing them based on functionality, businesses can choose the most suitable carts for their specific needs.

Categorizing material handling carts based on functionality:

-

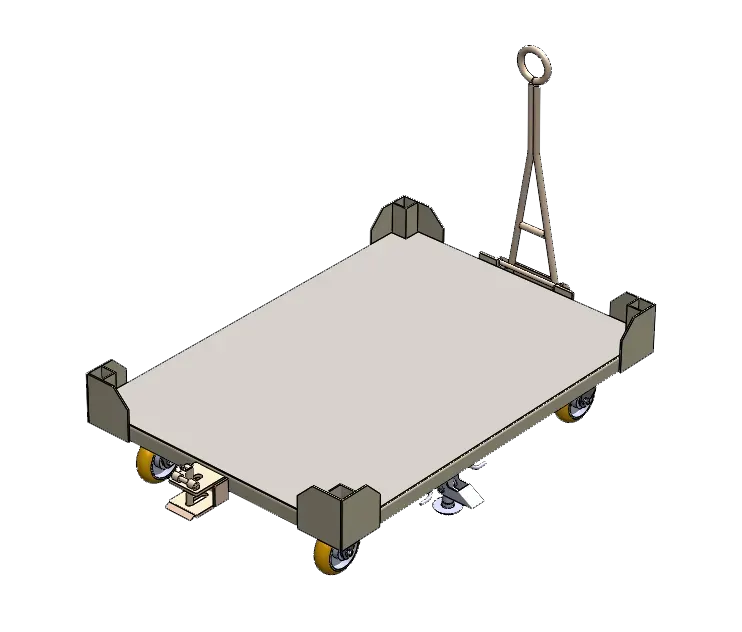

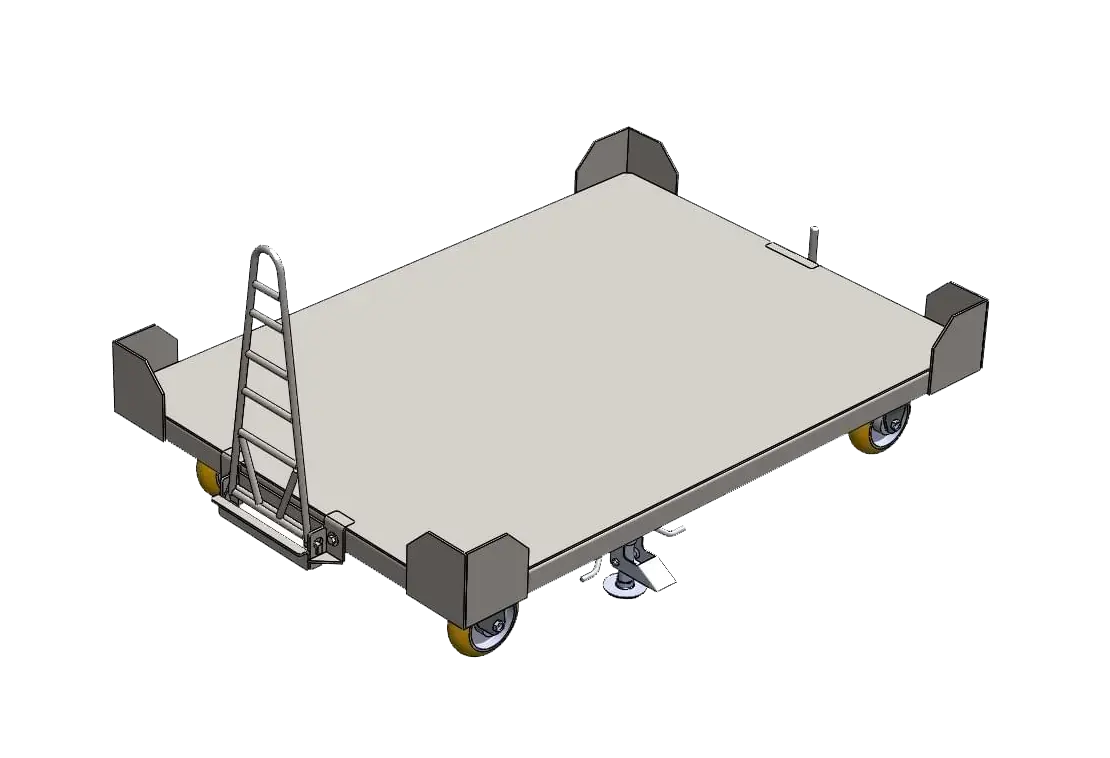

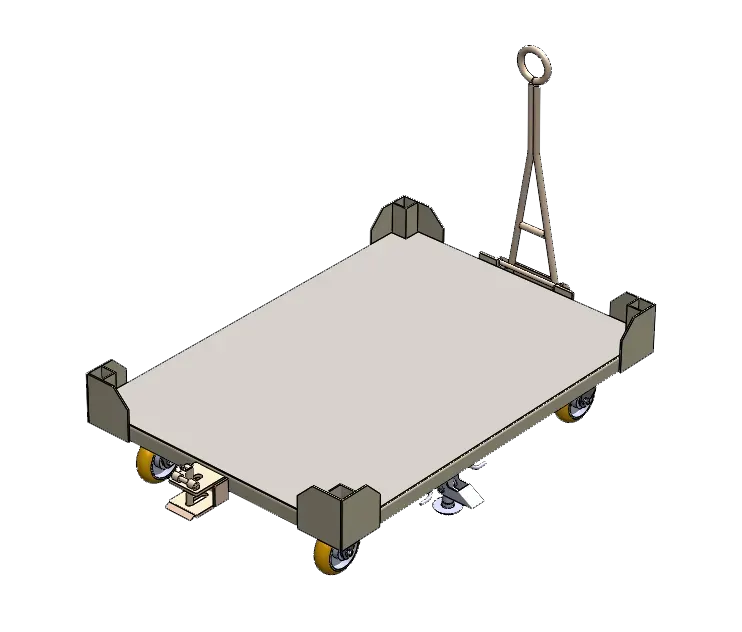

Platform Carts: These carts have a large, flat surface and are ideal for transporting large or heavy items. They are commonly used in warehouses, distribution centers, and manufacturing facilities.

-

Shelf Carts: These carts are ideal for moving and organizing smaller objects since they have multiple levels of shelves or bins. They are frequently utilized in sectors like retail and healthcare where organization and inventory control are crucial.

-

Tilt Carts: Tilt carts are designed with a tilting mechanism that allows for easy loading and unloading of materials. They are frequently used in sectors like construction and the automobile industry where having quick access to supplies is essential..

-

Hand Trucks: Hand trucks, also known as dolly carts, are designed to transport bulky or heavy items vertically. They feature a pair of wheels and a flat platform or frame to support the load. Hand trucks are commonly used in industries where materials need to be moved up or down stairs or in tight spaces.

- Wire Mesh Carts: These carts are made of wire mesh panels, allowing for visibility and airflow. They are commonly used in industries where materials need to be easily visible or ventilated, such as food service or laundry facilities.

- Flatbed Carts: These carts have a large, flat surface and are often used for transporting heavy or bulky items. They can be pulled or pushed manually or attached to a vehicle for towing.

By understanding the different types and designs of material handling carts, businesses can select the most suitable option for their specific material transportation needs.

How Material Handling Carts Improve Efficiency

The use of these carts provides significant benefits in terms of improving efficiency and optimizing the movement of materials within a facility. Here are some ways in which these carts contribute to increased efficiency:

Streamlining material movement with material handling carts:

These carts streamline the movement of materials within a facility by providing a dedicated platform for transporting items. This eliminates the need for employees to carry items manually, reducing the risk of injuries and fatigue. With the use of carts, employees can move larger quantities of materials in less time, resulting in increased overall efficiency.

Reducing labor costs and increasing productivity:

Material handling carts enable employees to transport materials more efficiently, reducing the time and effort required for manual handling. This not only increases productivity but also helps reduce labor costs by minimizing the need for additional manpower. By optimizing the material transportation process, businesses can accomplish more in less time, resulting in significant time and cost savings.

These carts also contribute to increased productivity by simplifying the process of loading and unloading materials. With features such as tilt mechanisms or adjustable heights, carts provide easy access to materials, allowing employees to perform tasks more quickly and efficiently.

In addition to improving efficiency and productivity, material handling carts also enhance overall workplace safety by reducing manual handling risks. By minimizing the potential for injuries and accidents caused by lifting heavy items, businesses can create a safer work environment for their employees.

Factors to Consider When Choosing Material Handling Carts

When selecting carts for your business, several factors need to be taken into consideration to ensure they meet your specific requirements. Some important factors to consider include:

Weight capacity and load-bearing capabilities:

It is crucial to determine the weight capacity and load-bearing capabilities of the carts you are considering. Basically, this ensures that the carts can handle the materials you need to transport without compromising safety or efficiency. Choosing carts with a higher weight capacity than required will provide an extra margin of safety and flexibility.

Maneuverability and ease of transport:

Consider the layout and dimensions of your facility when selecting material handling carts. Choose carts that are easy to maneuver in tight spaces and can navigate through doorways or narrow aisles as needed. In fact, carts with swivel casters or ergonomic handles can improve maneuverability and make transportation more convenient.

Durability and maintenance requirements:

Select carts made from durable materials that can withstand the demands of your specific industry. Consider factors such as resistance to corrosion, impact, or extreme temperatures. Additionally, evaluate the maintenance requirements of the carts, including cleaning, lubrication, and any specific care instructions.

By carefully considering these factors, you can ensure that the material handling carts you choose are suitable for your specific needs, leading to optimal performance and longevity.

Best Practices for Using Material Handling Carts

To achieve maximum efficiency and safety when using material handling carts, it is essential to follow best practices. Some key best practices include:

Proper loading and securing of materials:

Ensure that materials are loaded onto the carts securely, making use of straps, tie-downs, or other appropriate securing methods. This will prevent accidental spills or shifting of materials during transportation. Also, proper loading techniques help distribute the weight evenly on the cart, ensuring stability during transport.

Safety guidelines for operating material handling carts:

Train employees on safe operating procedures when using these carts. This includes guidelines on how to navigate corners or congested areas, how to use brakes or locks when necessary, and how to avoid overloading the carts beyond their weight capacity. Above all, educating employees on safe practices can significantly reduce the risk of accidents or injuries.

Regular inspection and maintenance for optimal performance:

Perform regular inspections of the material handling carts to identify any signs of wear, damage, or malfunction. This includes checking wheels, handlebars, brakes, and any other mechanical components. Also, address any issues promptly to ensure the carts remain in good working condition for optimal performance.

By adhering to these best practices, businesses can make the most efficient and safe use of their material handling carts, increasing productivity and reducing the risk of accidents or damage.

How to Select the Right Material Handling Carts for Your Needs

Selecting the right cart for your business requires careful consideration of your specific material transportation requirements. Here are some steps to help you in the selection process:

Assessing your material transportation requirements:

Evaluate the types of materials you need to transport, their sizes, and weights. Consider the frequency and volume of material movement within your facility. This will help determine the appropriate size, weight capacity, and design features required in a material handling cart.

Considering space limitations and facility layout:

Take into account the dimensions of your facility and any space constraints that may impact cart maneuverability. Measure doorways, aisles, or storage areas to ensure carts can navigate smoothly. Ultimately, this will prevent any potential disruptions or damage caused by carts that are too large for your available space.

Evaluating cost-effectiveness and return on investment:

Consider the upfront cost as well as the long-term benefits of investing in material handling carts. Evaluate the potential cost savings in terms of increased productivity, reduced labor costs, and improved workflow. Analyzing the return on investment will help you make an informed decision in selecting carts that provide the best value for your business.

By carefully assessing your material transportation requirements, considering your facility layout, and evaluating the cost-effectiveness, you can select the right material handling carts that align with your business needs.

Key Features to Look for in Material Handling Carts

When selecting material handling carts, it is essential to consider key features that contribute to optimal performance and user satisfaction. Some important features to look for include:

Ergonomic design for improved safety and user comfort:

Choose carts that are ergonomically designed with features such as cushioned handles, adjustable heights, or anti-slip surfaces. Ergonomic design reduces the risk of strain or injuries on employees, promoting a safe and comfortable working environment.

Versatility and adaptability for different material types:

Carts that offer adjustable shelves or modular configurations provide flexibility in handling a variety of material sizes and types. Consider carts that can be easily modified or reconfigured to accommodate changing material transportation needs.

Integration with automated systems and technology:

In industries where automated systems are being utilized, consider material handling carts that can integrate seamlessly with these systems. Features such as RFID tracking, barcode scanning, or compatibility with conveyor belts can further enhance efficiency and accuracy in material transportation.

By prioritizing these key features, businesses can select material handling carts that contribute to improved safety, efficiency, and productivity in their operations.

How to Maintain and Extend the Lifespan of Material Handling Carts

Proper maintenance is essential to ensure the longevity and optimal performance of these carts. Here are some maintenance practices to consider:

Cleaning and routine maintenance practices:

Regularly clean the carts, removing any debris or spills that may impact their performance. In addition, inspect and maintain moving parts such as wheels, handles, and hinges. Lubricate as needed, following the manufacturer’s recommendations. Essentially, cleaning and routine maintenance will help prevent damage or malfunctions.

Troubleshooting common issues:

Educate employees on common issues that may arise with material handling carts and provide guidance on how to address them. This includes issues such as wheel misalignment, loose bolts or screws, or worn-out components. By empowering employees to troubleshoot minor issues, businesses can prevent more significant problems and extend the lifespan of the carts.

Replacing worn-out components and upgrading as needed:

Monitor the condition of the carts and identify any worn-out or damaged components. Replace these components promptly to ensure the cart’s continued functionality and safety. Additionally, consider upgrading carts as needed to take advantage of new technologies or features that can further improve efficiency or address specific material transportation challenges.

By implementing regular maintenance practices, promptly addressing issues, and upgrading carts when necessary, businesses can extend the lifespan of their material handling carts, ensuring they provide long-term value and performance.

Conclusion

Material handling carts are indispensable tools for efficiently moving and transporting materials within a facility. They offer numerous benefits, including increased productivity, streamlined operations, improved workplace safety, and enhanced ergonomics. By considering factors such as weight capacity, maneuverability, and durability, businesses can choose the right carts for their specific needs.

Implementing best practices such as proper loading, following safety guidelines, and regular maintenance can further optimize cart usage. By exploring accessories, customizations, and key features, businesses can enhance the functionality, versatility, and adaptability of their material handling carts.

Proper maintenance practices and selecting reputable brands and suppliers are essential to maximize cart lifespan and ensure reliable performance in the long run. By following this complete guide, businesses can make informed decisions and fully leverage the benefits of material handling carts, ultimately improving efficiency, productivity, and overall operational effectiveness.

Customize Your Own & Get a FREE Estimate!

Simply e-mail us at sales@plexformps.com with all your information

OR call us today & speak to one of our packaging professionals