Discover how stack racks can maximize storage space, improve organization, and enhance efficiency in various industries.

Read More

What are custom wire racks?

Custom wire racks are adaptable storage solutions that are built and customized to match your exact storage requirements. They are constructed from robust wire mesh or metal rods, ensuring durability and strength. These racks are popular among organizations and industries that need effective and organized storage solutions.

Benefits of custom wire racks

There are several benefits to using custom wire racks for your storage needs.

Firstly, they maximize storage space by utilizing vertical space efficiently. These racks can be designed to fit the exact dimensions of your space, allowing you to make the most of every inch. As a result. this can significantly increase your storage capacity and help you optimize your operations.

Secondly, custom wire racks improve organization and accessibility. With configurable configurations and attachments, you may build separate compartments for different objects, making it easier to find and retrieve what you need quickly. Consequently, this can increase productivity and save crucial time.

Another benefit is their durability and strength. These racks are designed to withstand heavy loads and can support various types of inventory or equipment. For this reason, this makes them an ideal choice for industries that deal with heavy or bulky items.

Furthermore, these racks are adaptable and versatile. They may be readily modified or expanded to meet your changing storage demands, giving you a versatile and adaptable storage solution.

Types of custom wire racks

Custom wire racks come in various types, catering to different storage requirements. Some common types include:

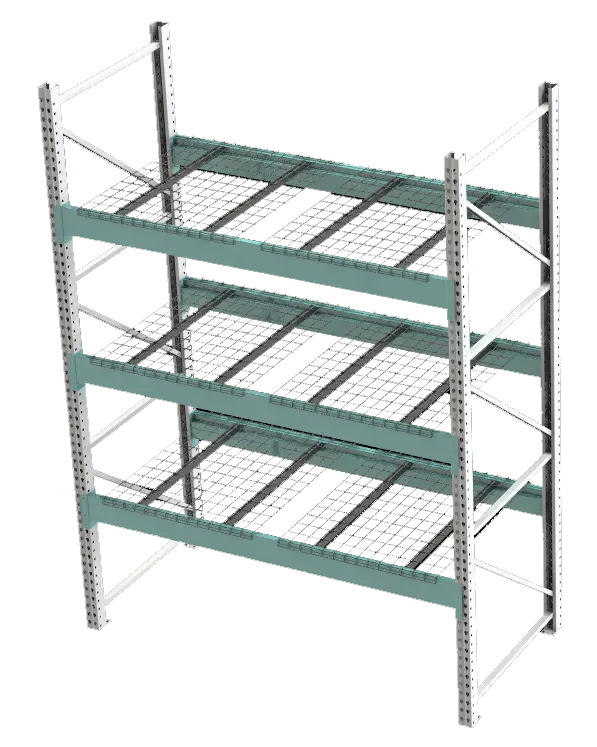

- Wire shelving racks: These racks feature wire shelves that can be adjusted to different heights, allowing for versatile storage options.

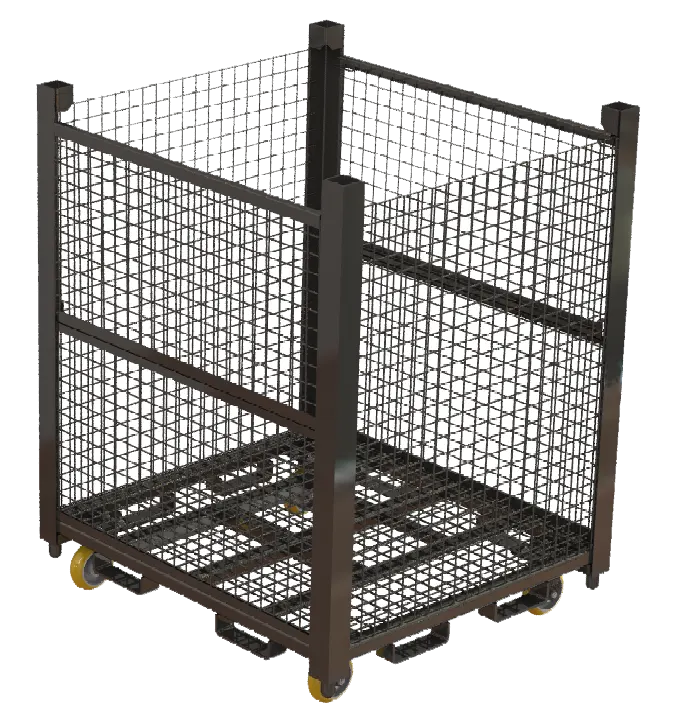

- Wire basket racks: These racks feature wire mesh baskets that are great for holding smaller items or products that need to be easily visible.

- Rolling wire racks: These racks have wheels for effortless mobility, making them perfect for industries that require frequent transportation of goods.

- Pallet racks: These racks, which are frequently used in warehouses and distribution centers, are specifically built for holding palletized items.

The type of custom wire rack you choose will depend on your specific storage needs and industry requirements.

How do custom wire racks work?

Custom wire racks operate by offering a safe and secure place to store your belongings. The open wire structure promotes airflow and visibility, lowering the risk of moisture and dust formation. This is especially useful for industries that demand good ventilation or cleanliness, such as the food and healthcare sectors.

These racks can be customized with a variety of accessories, including dividers, shelves, and labels, to improve storage and accessibility. The adjustable nature of wire racks allows you to tailor the configuration to different sizes and types of products.

Racks are often mounted on the floor or wall for stability and safety. They can be secured using bolts or brackets, depending on the design and installation specifications.

Considerations for choosing custom wire racks

When choosing these racks for your storage needs, there are several factors to consider:

- Storage requirements: Assessing your storage needs and understanding the type and quantity of items you need to store is crucial in determining the size, configuration, and accessories required for your racks.

- Space constraints: Measuring the available space and taking into account any height, width, or depth restrictions can help guarantee that the racks fit effortlessly into your environment.

- Weight capacity: It is important to determine the maximum weight your custom wire racks need to support to avoid any potential safety hazards.

- Accessibility: Consider how frequently you need to access your stored products, as well as whether easy visibility and accessibility are necessary for efficient operations.

- Industry regulations: Different industries may have specific regulations or standards for storage solutions. Ensure that your racks comply with any relevant industry guidelines or safety requirements.

Taking these considerations into account will help you choose the right racks that meet your storage requirements and contribute to an organized and efficient workspace.

Custom wire racks vs standard racks

Custom wire racks offer various advantages over standard racks. While standard racks may be sufficient for typical storage needs, custom wire racks provide personalized solutions to specific requirements.

Custom wire racks are designed to maximize storage space by utilizing every inch of available space. Standard racks often come in fixed sizes and configurations, which may not optimize your storage capacity.

Additionally, custom wire racks offer flexibility and adaptability. They can be adjusted or expanded as your storage needs change, while standard racks may lack the customization options required for efficient organization.

Custom wire racks for different industries

These racks are widely used across various industries due to their versatility and functionality. Here are some examples of how these racks can be beneficial in different sectors:

1. Retail industry:

In the retail industry, these racks can be utilized to effectively showcase products and inventory. They can be tailored to the precise size and shape of the objects, making them both visually appealing and conveniently accessible to clients.

2. Food and beverage industry:

Custom wire racks are ideal for the food and beverage industry due to their hygienic design and enough airflow. They can be used to store materials, perishable objects, or tools while maintaining optimum ventilation and lowering the risk of contamination.

3. Healthcare industry:

Hospitals, clinics, and laboratories can use these racks to store medical supplies, equipment, and samples. The racks’ open wire design allows for easy view and access, making it possible to retrieve necessary items quickly.

4. Warehouse and logistics industry:

Custom wire racks are extremely useful in the warehouse and logistics industries. Essentially, they can be utilized to effectively store and arrange goods, resulting in easy access and streamlined processes. Wire racks’ adaptability allows for the storage of a wide range of sizes, including palletized goods.

How to choose the right custom wire rack for your needs

Choosing the right custom wire rack involves a systematic process to ensure that it meets your specific storage requirements:

1. Assessing your storage needs

Start by assessing the type and quantity of items you need to store. Consider factors such as shape, size, weight, and any special requirements for your stored items.

Key factors to consider in assessing your storage needs:

- Inventory type: Determine the type of inventory, such as boxes, containers, or specialized equipment, that you need to store on the racks.

- Weight capacity: Calculate the maximum weight that the racks will need to support.

- Storage volume: Analyze the volume of storage space you require.

2. Measuring your space

Measure your available area accurately, taking into account any height, width, or depth limits. These measurements will be critical in selecting the rack size and configuration that will work best with your environment.

3. Determining the optimal rack size and dimensions

Work with a custom wire rack manufacturer to identify the best rack size and dimensions based on your storage requirements and space specifications.

4. Selecting materials for your custom wire racks

Consider the materials utilized to build the unique wire racks. The materials used will be determined by considerations like as durability, industry regulations, and aesthetic options.

5. Designing the rack configuration

Work closely with the manufacturer to design the rack configuration that best suits your storage needs. This may include the inclusion of shelves, dividers, or other accessories to optimize organization and accessibility.

6. Choosing the right finish for your custom wire racks

The finish of your racks is vital for both aesthetics and durability. Therefore, consider finishes that are resistant to corrosion, scratching, or fading, depending on your particular requirements.

Conclusion

Custom wire racks are a versatile and practical solution for increasing storage space and enhancing organizational efficiency in a variety of sectors. By examining your storage requirements and collaborating with reliable suppliers, you can develop and utilize racks that fit your exact specifications. Investing in custom wire racks can not only maximize your storage space, but will also help to improve workplace efficiency and productivity.