Explore cutting-edge designs, practical applications, and the numerous benefits of advanced automotive racking systems.

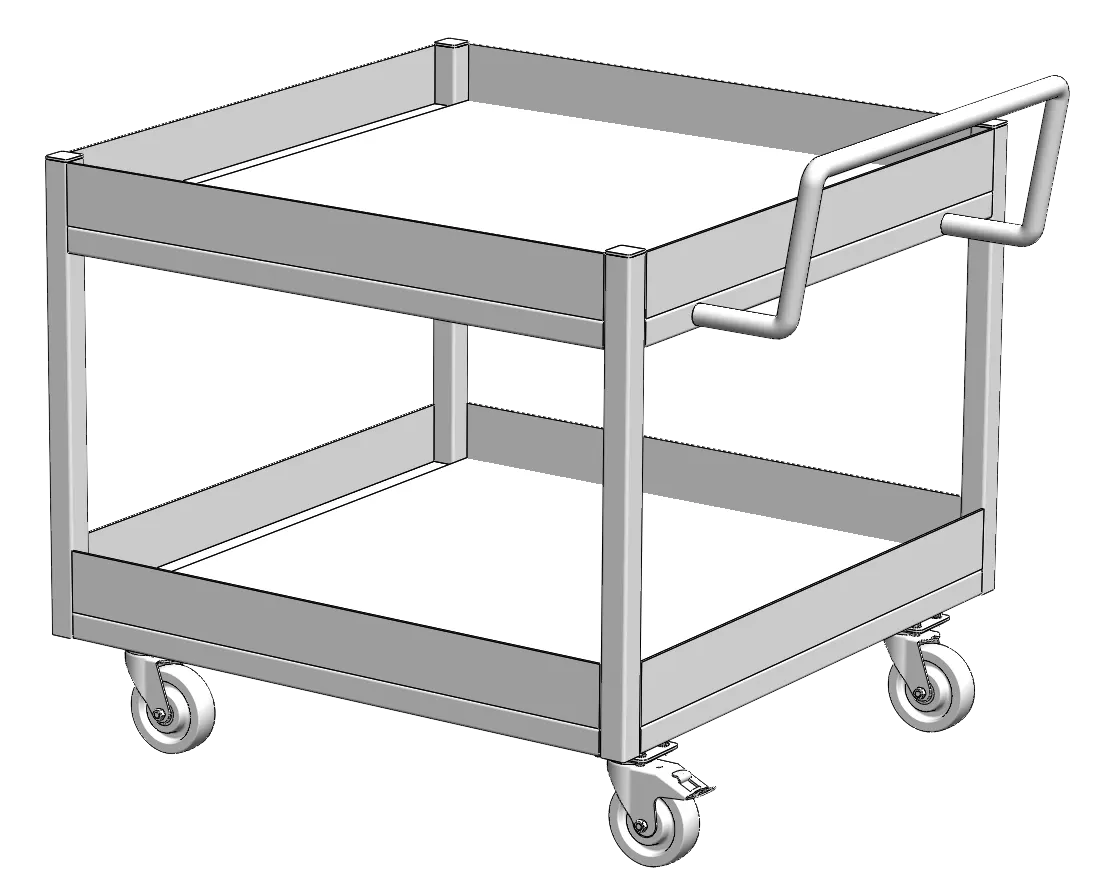

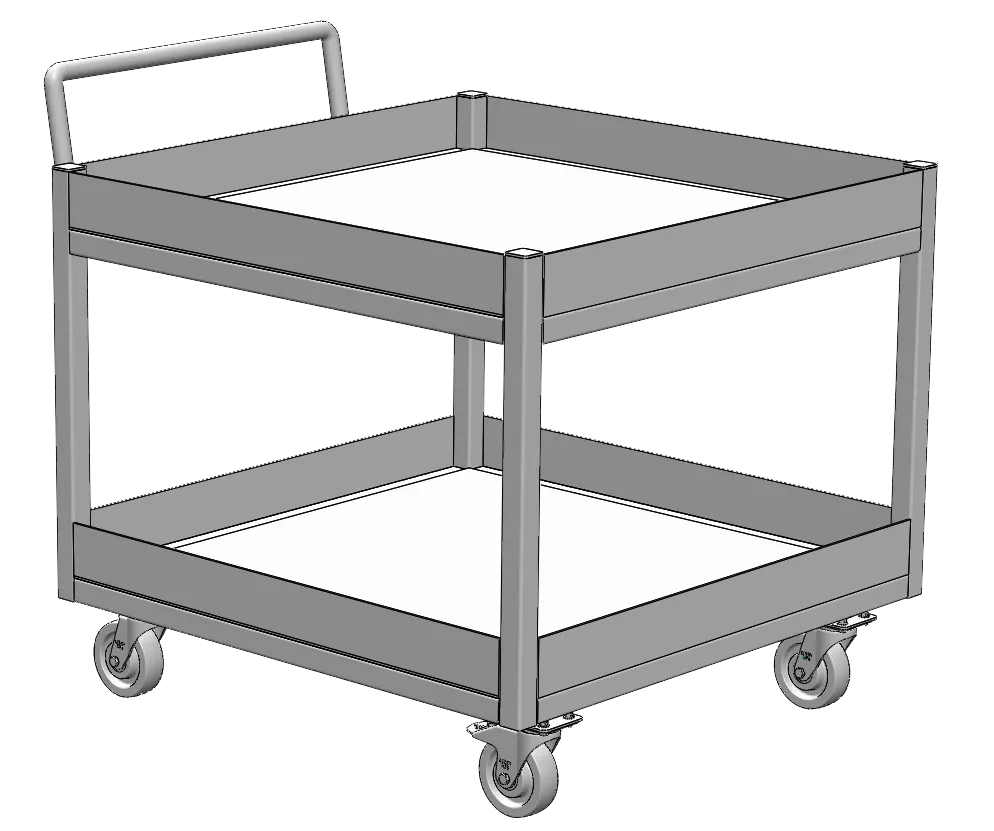

Read MoreCustom Metal Cart: Transport, Organize, Optimize

What is a Custom Metal Cart?

A custom metal cart is a specialized tool used in industrial settings for transporting goods, equipment, and materials. Unlike standard carts, custom metal carts are designed and tailored to meet the specific needs and requirements of a particular industry or application. These carts are constructed using high-quality metals such as steel or aluminum, which provide exceptional durability and strength for heavy-duty usage.

Key Takeaways:

- -> A custom metal cart is a specialized tool designed for industrial settings.

- -> These carts are customized to fit specific needs and requirements.

- -> They are constructed using high-quality metals for durability and strength.

Benefits of Custom Metal Carts

Custom metal carts offer numerous benefits in industrial operations, making them an essential tool for enhancing efficiency and productivity. Some of the key benefits include:

-

Increased efficiency and productivity in industrial operations: Custom metal carts are designed to optimize workflow by providing a convenient and organized means of transporting goods. These carts make it simple for employees to carry supplies or machinery from one place to another, cutting down on labor-intensive manual handling and boosting productivity.

-

Customization options for specific industry needs: One of the major advantages of custom metal carts is the ability to customize them according to specific industry requirements. Businesses can choose the dimensions, size, and features of the cart to best suit their unique needs. Ultimately, this customization allows for better organization and efficiency in the workplace.

-

Durability and strength of metal carts in heavy-duty applications: Custom metal carts are built to withstand the rigors of heavy-duty usage. By utilizing premium metals, these carts can withstand frequent and persistent use without undergoing any compromise to their structural soundness. After all, this durability makes them suitable for industries that require carts to withstand harsh conditions and heavy loads.

Different Types of Custom Metal Carts

Custom metal carts come in various types, each designed to serve a specific purpose in industrial settings. Some of the common types include:

-

Utility carts for transporting tools and equipment: These carts are equipped with multiple compartments, shelves, and hooks to securely store and transport tools and equipment.

-

Material handling carts for moving heavy loads: The reinforced frames and platforms of these carts ensure the secure transport of heavy materials or equipment.

-

Workstation carts for optimizing workflow in specific tasks: Workstation carts are made to give employees a movable, well-organized work surface so they can do particular jobs quickly.

Customizing Your Metal Cart

To maximize the functionality and efficiency of your custom metal cart, it is essential to customize it according to your specific needs. Some key aspects to consider when customizing your metal cart include:

-

Choosing the right dimensions and size: Determine the optimal dimensions and size of the cart in consideration of your workstation, guaranteeing its seamless integration with your operations. Consider doors, elevators, and maneuverability when calculating the ideal measurements.

-

Selecting the appropriate metal material: When selecting the metal material for the cart, keep in mind its intended application. Stainless steel is widely utilized due to its corrosion resistance and simplicity of cleaning, whereas aluminum provides lightweight durability.

-

Custom features such as partitions, shelves, and drawers: Customize the cart with features such as partitions, shelves, or drawers to improve organization and storage capacities. After all, these additional features can significantly improve the cart’s functionality and efficiency.

Importance of Ergonomics in Custom Metal Carts

Ergonomics plays a crucial role in the design of custom metal carts, as it directly impacts worker comfort, safety, and productivity. By incorporating ergonomic features into the cart design, businesses can realize the following benefits:

-

Designing carts with adjustable heights and ergonomic handles: Adjustable heights enable workers to put the cart at a more comfortable level, reducing strain and fatigue. Ergonomic handles offer a stable and comfortable grip, lowering the risk of injury and increasing maneuverability.

-

Reducing worker fatigue and strain-related injuries: Prolonged usage of carts lacking sufficient ergonomic elements might result in problems such as back strain and repetitive strain injuries (RSI). Therefore, ergonomic design lowers the likelihood of these injuries, enhancing worker health and wellbeing.

-

Improving overall workplace safety and efficiency: The possibility of accidents and injuries is decreased with ergonomically constructed carts, making the workplace a safer place to work. Employee comfort and reduced weariness enable more focused and effective work performance, which boosts total production.

Implementing Custom Metal Carts in Industrial Operations

To successfully implement custom metal carts in industrial operations, consider the following steps:

-

Assess the current workflow and identify areas for improvement: Before customizing or acquiring custom metal carts, evaluate your current workflow and identify areas where carts can enhance efficiency. In particular, considering factors such as material transport, storage needs, and task optimization is essential.

-

Collaborate with an experienced cart manufacturer to design a tailored solution: Work closely with a reliable custom cart maker to create a cart that is personalized to your exact needs. In essence, their skills and experience will ensure that the cart is effective in improving your operations.

-

Training employees on proper use and maintenance of custom metal carts: It is essential to provide thorough training to your employees on how to properly use and maintain the custom metal carts. Basically, this will ensure that the carts are operated safely and efficiently, prolong their lifespan, and prevent any accidents or damage caused by overuse.

Key Considerations for Choosing a Custom Metal Cart

When choosing a custom metal cart, there are several key considerations to take into account:

-

Budget constraints and cost-effectiveness: Determine your budget and evaluate the cart’s long-term cost-effectiveness. While high-quality custom metal carts may have a higher price tag, they provide better durability and can result in long-term savings.

-

Compatibility with existing equipment and infrastructure: Ensure that the custom metal cart is compatible with your existing equipment and infrastructure. This includes factors such as wheel size, maneuverability in tight spaces, and compatibility with conveyor systems, if applicable.

-

Warranty and after-sales support: Consider the manufacturer’s warranty and after-sales support. A warranty ensures that any flaws or difficulties with the cart will be resolved easily and without further expense to you.

Maintaining Your Custom Metal Cart

Regular maintenance of your custom metal cart is essential to ensure its proper functionality and longevity. Here are some maintenance tips:

-

Regular cleaning and inspection: Cleaning the cart on a regular basis will help to remove dirt, debris, and stains. Also, inspect the cart for any signs of wear or damage, and address them immediately.

-

Lubrication and tightening of loose components: To ensure smooth operation, lubricate moving parts such as wheels and hinges. To ensure stability and safety, adjust any loose components on a regular basis.

-

Prompt repairs or replacements for damaged parts: If any part of the cart becomes damaged or worn out, arrange for prompt repairs or replacements to prevent further deterioration.

Custom Metal Cart Design Trends

The design of custom metal carts is constantly evolving to meet the changing needs of industrial operations. Some of the latest design trends in custom metal carts include:

-

Integration of smart technology for enhanced tracking and monitoring: Many custom metal carts now feature integrated sensors and technology that enable real-time tracking of inventory and assets. As a result, this improves efficiency and simplifies inventory management processes.

-

Optimization for sustainability and eco-friendly practices: In order to lessen their impact on the environment, custom metal carts are currently being developed using environmentally friendly materials and production techniques. Using recyclable materials and maximizing energy use during production are two examples of this.

-

Innovation in cart design for improved mobility and maneuverability: Custom metal cart manufacturers are always coming up with new ways to enhance the mobility and maneuverability of their products. This includes components like lightweight materials, adjustable handles, and swivel casters.

Conclusion

In conclusion, custom metal carts offer a wide range of benefits and can greatly enhance efficiency and functionality in industrial settings. By customizing these carts to fit specific needs and incorporating ergonomic features, businesses can optimize their workflow and improve overall productivity. To achieve long-term success with custom metal carts, carefully examine design, maintenance, and manufacturer selection. Embracing the newest trends and cooperating with industry experts can improve the effectiveness of custom cart solutions in industrial settings.

Customize Your Own & Get a FREE Estimate!

Simply e-mail us at sales@plexformps.com with all your information

OR call us today & speak to one of our packaging professionals