Explore innovative designs, practical applications, and the numerous benefits of utilizing a wine barrel rack for your facility.

Read MoreCorrugated Steel Bins: Discover the Versatility and Advantages

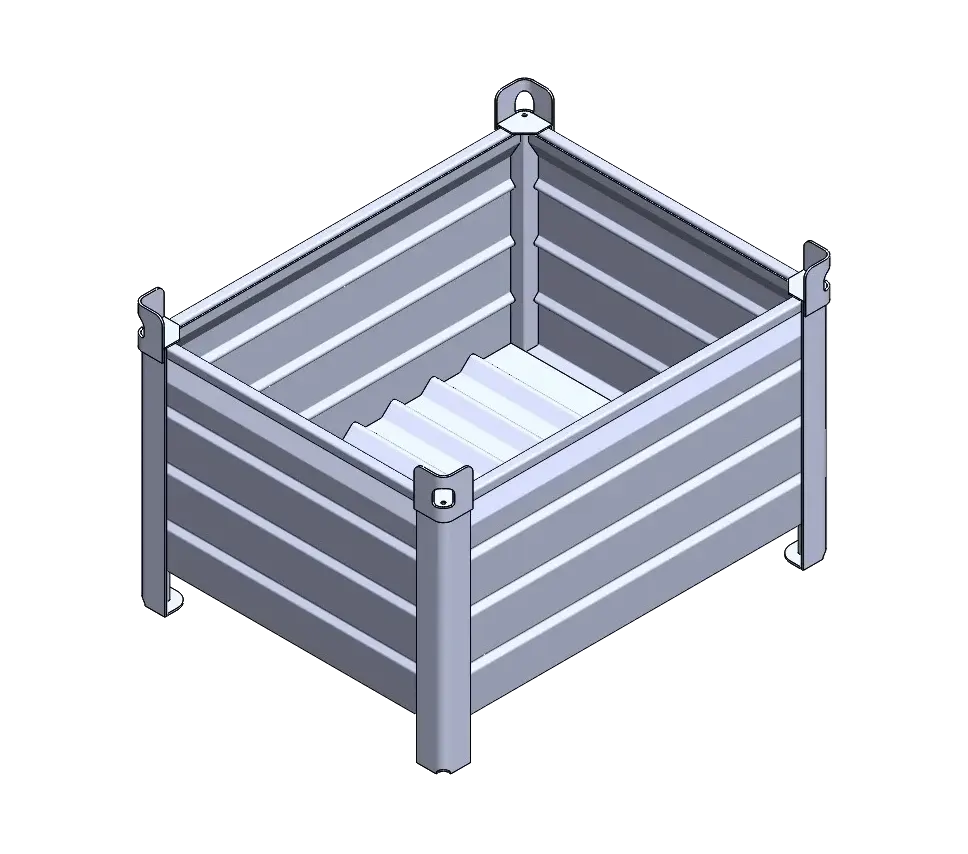

What are Corrugated Steel Bins?

Corrugated steel bins refer to containers made from corrugated galvanized steel sheets. These bins are constructed by folding and interlocking the steel sheets to create a sturdy and durable storage solution. Furthermore, they are commonly used in various industries for their strength, durability, and versatility.

Corrugated steel bins come in a range of sizes, shapes, and designs to suit different storage needs. They are known for their ability to withstand extreme weather conditions and their high resistance to corrosion, making them ideal for both indoor and outdoor applications.

Benefits and Importance of Corrugated Steel Bins

Durability and Strength

One of the key advantages of corrugated steel bins is their exceptional durability and strength. The corrugated design adds structural rigidity to the bins, allowing them to withstand heavy loads and resist deformation. As a result, this makes them suitable for storing and transporting bulky and heavy items without the risk of damage or collapse.

Weather Resistance

Corrugated steel bins are built to withstand various weather conditions, making them a reliable storage solution for both indoor and outdoor use. In fact, the galvanized coating on the steel sheets does provide excellent corrosion resistance, preventing rust and ensuring the bins can withstand exposure to moisture, UV rays, and extreme temperatures.

Versatility and Customization

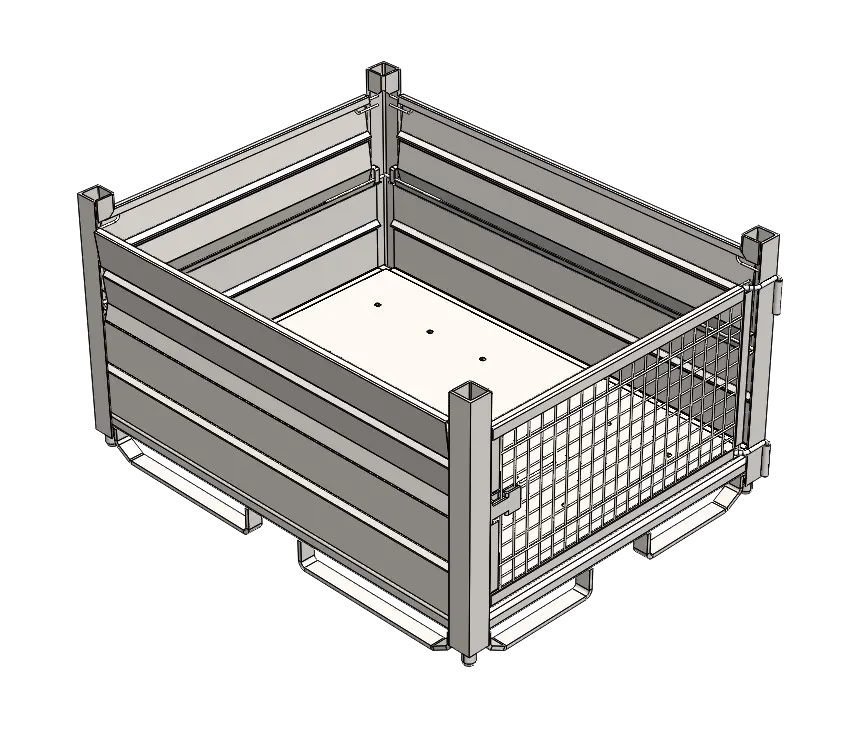

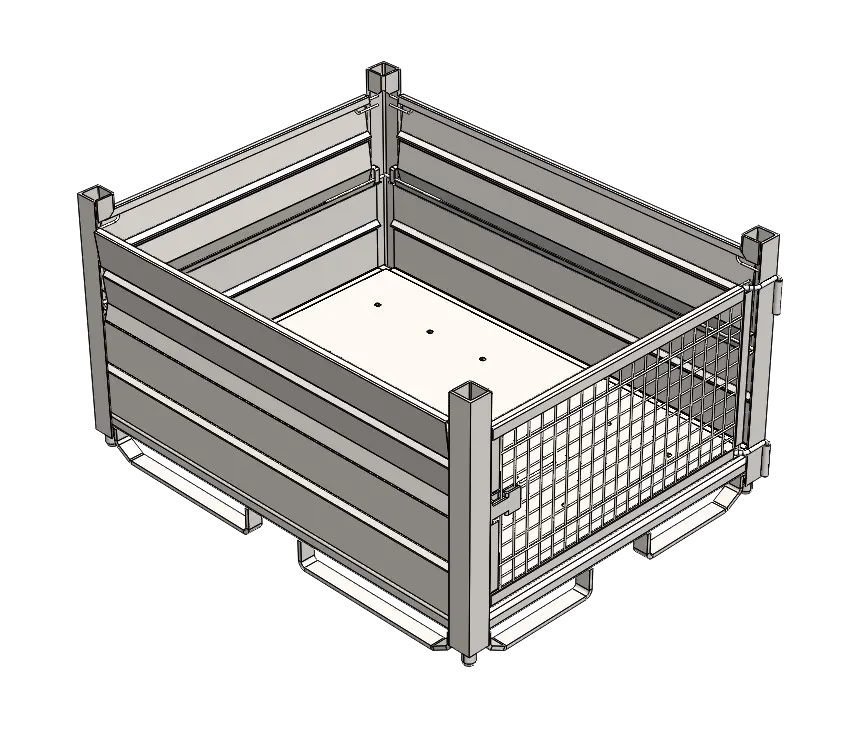

Corrugated steel bins offer great versatility in terms of size, shape, and design options. They can be customized to meet specific storage requirements, whether it’s for storing small parts in a warehouse or for large bulk storage in agricultural applications. Additionally, they can be easily modified with additional features such as dividers, lids, or access doors to optimize storage efficiency.

Cost-effectiveness

In comparison to other storage solutions, corrugated steel bins offer long-term cost savings. The durable construction and high resistance to damage mean they have a longer lifespan than alternatives like plastic or wooden bins. In addition, the cost of maintenance and repairs is minimal, making them a cost-effective investment for businesses in need of reliable storage solutions.

Environmentally-friendly Solution

Corrugated steel bins are an environmentally-friendly choice for storage solutions. The steel used in their construction is highly recyclable, reducing the demand for new materials. Moreover, the long lifespan of these bins reduces the need for frequent replacement, resulting in less waste generated over time.

Uses and Applications of Corrugated Steel Bins

Corrugated steel bins find applications in various industries due to their durability and versatility. Here are some of the common uses:

Agriculture and Farming

In the agricultural sector, these bins play a crucial role in the storage of crops, grains, and animal feeds. After all, they do provide a secure and weather-resistant solution for preserving agricultural produce, protecting it from pests, moisture, and spoilage.

Construction and Building Industry

The main use for these bins in the construction industry is for storing and transporting construction materials such as sand, gravel, cement, and other heavy-duty equipment. Their strength and durability ensure the safe and efficient storage of these materials on construction sites.

Waste Management and Recycling

Corrugated steel bins are utilized in waste management and recycling facilities for the collection, transportation, and storage of various waste materials. They are designed to withstand the harsh conditions associated with handling waste and are often used for the safe storage of recyclable materials before they are processed.

Industrial Storage and Transportation

Corrugated steel bins are commonly employed in industrial settings for the storage and transportation of raw materials, finished products, and components. Additionally, their robust construction and stackable design allow efficient utilization of space in warehouses, factories, and distribution centers.

Mining and Extraction Industry

The mining and extraction industry relies on these bins to store and transport minerals, ores, and mining by-products. Also, these bins are built to withstand the harsh conditions associated with mining operations and provide a secure and reliable storage solution for valuable resources.

How Corrugated Steel Bins Work

Structural Design and Features

Corrugated steel bins are designed with interlocking panels that create a rigid and durable structure. The corrugations in the steel provide added strength and improve the load-bearing capacity of the bins. In addition, reinforcements such as corner braces and base plates further enhance the structural integrity of the bins.

Assembly and Installation Process

The assembly process of corrugated steel bins typically involves folding and fastening the steel sheets together using screws or bolts. The panels are interconnected to form a complete bin, with additional reinforcement elements added as necessary. Consequently, installation can be done on-site or pre-built bins can be delivered and assembled at the desired location.

Proper Maintenance and Care

To ensure the longevity and optimal performance of these bins, regular maintenance is essential. This includes cleaning the bins to remove debris and maintaining the galvanized coating to prevent rust. In fact, any damage or wear should be promptly addressed through repairs and replacements to avoid compromising the integrity of the bins.

Factors to Consider when Choosing Corrugated Steel Bins

Size and Capacity

When selecting corrugated steel bins, it is crucial to assess the storage requirements and consider the size and capacity needed. Bins come in various dimensions, so choosing the right size ensures optimal utilization of space and cost-effective storage management.

Shape and Design Options

These bins are available in different shapes and designs to accommodate specific storage needs. Basically, understanding the available space and the type of items that are going into the bin, will help guide the decision on the appropriate bin shape and design to choose.

Material and Coating Selection

The choice of material and coating is another important consideration when selecting corrugated steel bins. Galvanized steel is the most common option due to its excellent corrosion resistance. Different coating options may be available based on specific requirements, such as chemical resistance or food-grade applications.

Accessibility and Safety Features

When choosing these bins, one should focus on the accessibility and safety features. Options such as access doors, locks, and safety interlocks can enhance convenience and ensure the secure storage of valuable or hazardous items.

Cost and Budget Considerations

Cost is a crucial factor for many businesses. It is important to evaluate the upfront cost of purchasing corrugated steel bins, as well as the long-term value in terms of durability and maintenance requirements. Balancing cost with quality will ensure a suitable investment in storage solutions.

How to Optimize Corrugated Steel Bins for Efficiency

Proper Loading and Unloading Techniques

To optimize the efficiency of these bins, it is important to use proper loading and unloading techniques. This includes distributing the weight evenly, avoiding overloading, and utilizing lifting equipment, such as forklifts or cranes, when necessary to minimize the risk of damage and accidents.

Organization and Labeling Systems

Implementing effective organization and labeling systems within corrugated steel bins can significantly enhance efficiency and ease of retrieval. This can include labeling bins with item descriptions, implementing a clear inventory system, and using dividers or compartments to separate different items.

Stackability and Space Optimization

The design feature of a corrugated steel bin is to be stackable, allowing for efficient use of vertical space. To optimize efficiency, it is important to ensure proper stacking techniques to prevent instability or damage to lower bins. Utilizing shelving or racking systems specifically designed for these bins can also enhance space optimization.

Recommended Accessories and Add-ons for Corrugated Steel Bins

Forklift Attachments

Forklift attachments, such as bin tippers or rotators, can facilitate the loading and unloading of corrugated steel bins. These accessories increase efficiency and reduce manual labor in handling heavy or numerous bins.

Shelving and Racking Systems

Shelving and racking systems designed for these bins can further enhance organization and optimize storage space. In addition, these systems provide a secure and organized solution for storing multiple bins, maximizing the available space and allowing for easier accessibility.

Lid and Cover Options

Lids and covers are available as optional accessories for corrugated steel bins. These additions provide additional protection against dust, moisture, and unauthorized access. They are particularly useful when storing sensitive or valuable items.

Security Features

For applications requiring extra security, these bins can be equipped with additional security features such as padlock hasps or tamper-evident measures. As a result, these additions ensure the safety and integrity of the stored items.

How to Maintain and Extend the Lifespan of Corrugated Steel Bins

Cleaning and Rust Prevention

Regular cleaning of corrugated steel bins is essential to remove debris, dirt, and chemicals that can cause damage or corrosion. Additionally, applying a protective coating or paint to areas prone to rust can help prevent corrosion and extend the lifespan of the bins.

Regular Inspection and Repairs

Periodic inspection of the bins is important to identify any signs of wear, damage, or potential issues. Therefore, proactive repairs and replacements should be conducted as needed to maintain the bins’ structural integrity and ensure safe storage.

Proper Storage and Handling

Proper storage and handling of these bins contribute to their longevity. In fact, storing bins in a suitable environment, away from direct sunlight or extreme temperatures is essential. It is important to handle the bins with care, avoiding impacts or rough handling that can lead to deformation or damage.

Corrugated Steel Bins vs. Other Storage Solutions

Comparison with Plastic Bins

Corrugated steel bins offer several advantages over plastic bins. After all, they provide better durability and strength, making them suitable for heavy-duty applications. Steel bins are highly resistant to impacts, while plastic bins are more prone to cracking or breaking under pressure. Furthermore, steel bins have better resistance to fire and UV rays, making them a safer option for long-term storage.

Advantages over Wooden Bins

Compared to wooden bins, corrugated steel bins offer greater durability and longevity. Steel bins are not susceptible to rot, insect damage, or warping, which can occur with wooden bins over time. They also offer better weather resistance and can be easily cleaned and maintained, reducing the risk of contamination or spoilage.

Cost Comparison with Traditional Storage Methods

While the upfront cost of these bins may be higher than traditional storage methods such as wooden crates, the long-term value and durability of steel bins often outweigh the initial investment. Steel bins have a longer lifespan, require minimal maintenance, and provide better protection for stored items, resulting in overall cost savings.

Conclusion

In conclusion, corrugated steel bins offer a comprehensive storage solution with numerous benefits and applications across various industries. Their durability, weather resistance, and versatility make them an ideal choice for a range of storage needs. By considering factors such as size, shape, and material, businesses can choose the most suitable bins to optimize storage efficiency. With proper maintenance and care, these bins can provide reliable and long-lasting storage solutions. So, explore the wide range of applications and benefits of corrugated steel bins and discover how they can enhance your storage operations.

Customize Your Own & Get a FREE Estimate!

Simply e-mail us at sales@plexformps.com with all your information

OR call us today & speak to one of our packaging professionals