Explore innovative designs, practical applications, and the numerous benefits of utilizing a wine barrel rack for your facility.

Read MoreCoil Racks: Revolutionizing the Handling of Heavy Metal

Coil racks are an essential tool for organizing and efficiently managing warehouse operations. They provide a systematic and safe way to store and manage coils, ensuring their protection and optimal utilization of warehouse space. In this article, we will explore the definition of coil racks, their importance, and the different types available. We will also explore into how coil racks work, their advantages compared to other storage methods, and best practices for their maintenance and usage.

What are Coil Racks?

Coil racks are storage solutions designed to organize and store coils efficiently in a warehouse setting. Coils are typically heavy and bulky, making them challenging to store and manage without the right system in place. These racks provide a structured approach to coil storage, ensuring easy access, protection, and maximum utilization of space.

The purpose and benefits of coil racks in a warehouse setting are multifold. Firstly, they protect coils from damage and deformation caused by improper storage or movement. Coils, being valuable assets, need to be handled with care to prevent any loss in quality. Secondly, these racks help optimize space utilization by maximizing vertical storage, reducing clutter, and allowing for easy identification and retrieval. Thirdly, these racks enhance operational efficiency by facilitating a streamlined and organized workflow, reducing the time spent looking for coils, and minimizing the risk of accidents or injuries.

It is crucial to organize coils properly in the warehouse to ensure efficient operations. When coils are scattered or stored haphazardly, it can lead to a range of issues including damage, decreased productivity, and safety hazards. Therefore, these racks will provide a systematic framework for storing coils, ensuring they are easily accessible, protected, and well-organized.

Why are Coil Racks Important?

Coil racks play a vital role in warehouse management due to their numerous advantages. Firstly, they protect coils from damage and deformation that can occur during storage or handling. Coils are often made of delicate materials or have specific tolerances, and any mishandling can result in costly damage or product defects. By utilizing these racks, coils can be stored securely and protected from potential harm.

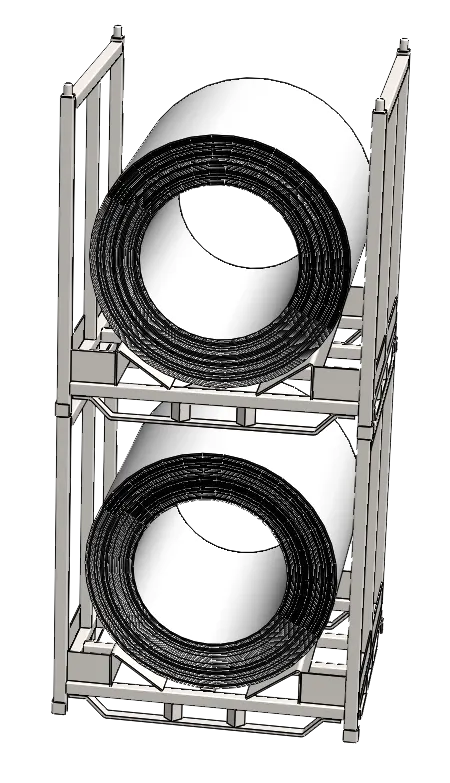

Secondly, these racks optimize space utilization in the warehouse. Instead of leaving coils lying on the floor or stacked in an unorganized manner, coil racks enable vertical storage, making efficient use of the available space. This not only maximizes storage capacity but also reduces clutter and improves visibility, making it easier to locate and retrieve coils when needed.

Thirdly, coil racks enhance operational efficiency. By providing a structured and organized storage system, these racks contribute to a streamlined workflow. Warehouse staff can quickly and easily identify the coils they need, reducing the time spent searching and minimizing any disruptions to the overall operations. As a result, this improved efficiency translates into increased productivity and cost savings for the warehouse.

Types of Coil Racks

There are several types of coil racks available, each designed to cater to specific storage requirements. The most common types of racks are vertical coil racks, horizontal coil racks, and customized coil racks.

1. Vertical Coil Racks: These racks are designed to store coils in a vertical position. Basically, they consist of a vertical frame with support arms that hold the coils in place. This type of rack is ideal for situations where space is limited, as it allows for maximum vertical storage.

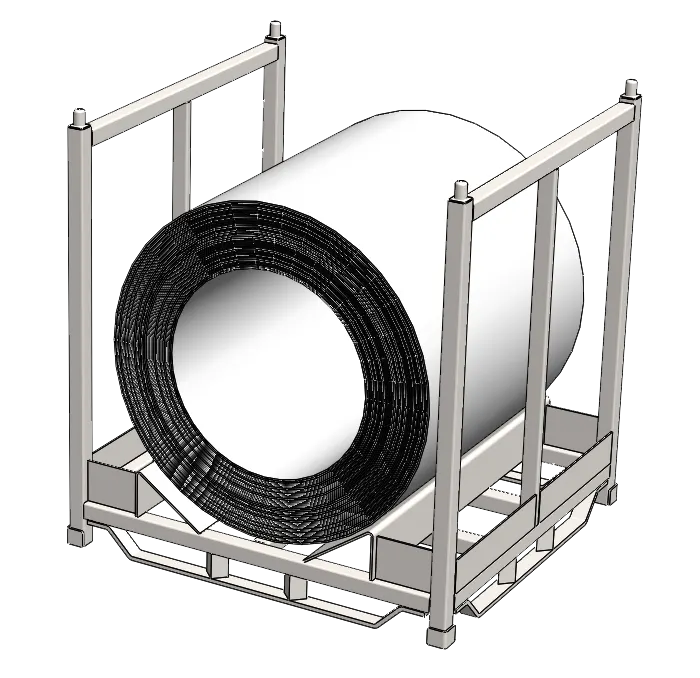

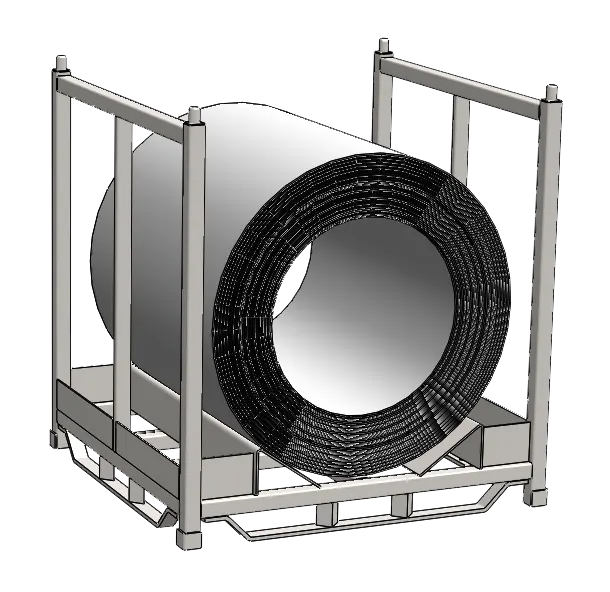

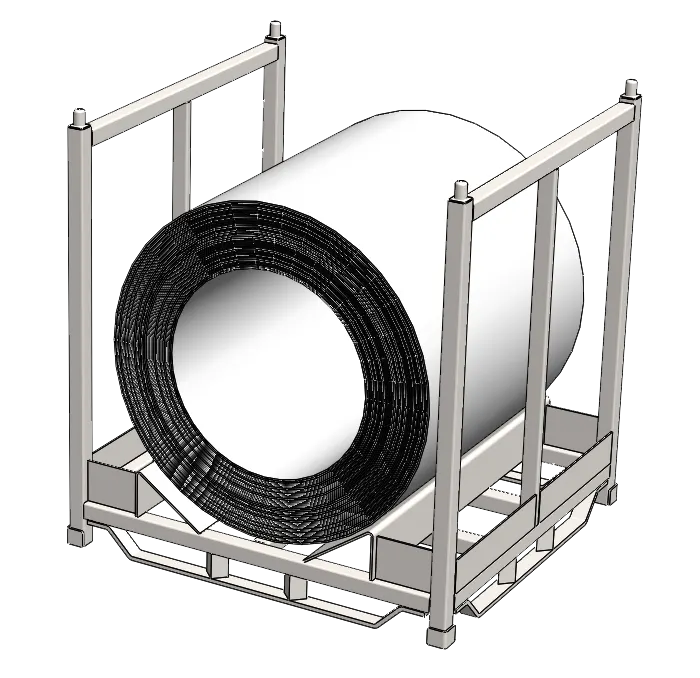

2. Horizontal Coil Racks: This style of rack, as the name suggests, stores coils in a horizontal position. Also, they feature individual compartments to hold each coil securely. These racks are perfect for larger coils that cannot be stored vertically or when easy accessibility and identification of individual coils are required.

3. Customized Coil Racks: These customized racks are designed to meet specific requirements and can be tailored to accommodate coils of varying sizes and weights. In fact, these racks are often made to order and can include additional features like adjustable arms, removable dividers, or specialized load-bearing capabilities.

The type of coil rack to choose depends on the specific needs and constraints of the warehouse, such as available space, coil dimensions, and workflow requirements. Consulting with a coil rack supplier or expert can help determine the most suitable option for a particular warehouse setup.

How do Coil Racks Work?

To make the most of coil racks, it is important to understand their design and structure, proper placement and storage techniques, as well as safety considerations.

The design of coil racks typically consists of a framework of metal beams or supports that secure the coils in place. Proper placement and storage techniques involve ensuring that coils are loaded onto the rack correctly, taking into account their weight, size, and shape. Using load-bearing supports or dividers can help prevent coils from shifting or falling, ensuring stability and safety.

When using coil racks, safety considerations must be a top priority. It is crucial to inspect racks regularly for any signs of damage or wear and tear. Proper training should be provided to employees involved in storing or retrieving coils to ensure they are aware of the proper handling procedures and safety protocols. Using appropriate material handling equipment, such as forklifts or cranes, can also contribute to safe and efficient coil rack usage.

Coil Racks vs. Other Storage Methods

Comparing coil racks with other storage options highlights the advantages of utilizing these racks for efficient warehouse operations. Let’s look at some commonly used storage methods and how they stack up against coil racks.

1. Pallet Racking Systems: Pallet racking systems are commonly used in warehouses to store a wide range of products, including coils. However, pallet racks may not offer the same level of protection and organization specifically tailored for coil storage. Coil racks, on the other hand, provide specialized features and structural support designed to secure and preserve coils effectively.

2. Floor Stacking: Floor stacking refers to storing coils directly on the warehouse floor, without any specific rack or support structure. While this may seem like a cost-effective solution, it lacks the organization and protection provided by coil racks. Floor stacking can result in damage, deformation, and decreased efficiency in locating and retrieving coils.

3. Shelf Storage: Shelf storage involves using shelves or racks with multiple levels to store and organize coils. While shelf storage can be suitable for smaller coils, it may not be as efficient for larger or heavier coils. Coil racks offer customized options that can accommodate coils of various sizes and weights more effectively.

Overall, coil racks provide dedicated storage solutions that are designed specifically for coils. They ensure protection, efficient space utilization, and streamlined operations.

Coil Rack Selection and Sizing

When choosing coil racks for a warehouse, several factors should be considered to ensure the optimal selection and sizing:

- Coil Dimensions: Evaluate the dimensions of the coils that need to be stored, including length, width, and diameter. Ultimately, this information will help determine the appropriate rack design and capacity required.

- Weight Capacity: Determine the maximum weight that these racks need to support. Essentially, this will ensure that the racks are capable of handling the specific weight of the coils being stored.

- Available Space: Assess the available space in the warehouse and consider any height or width constraints. This information will help determine the suitable rack height and configuration that can be accommodated.

- Workflow Requirements: Understand the workflow and operational needs of the warehouse. Consider factors such as accessibility, frequency of coil retrieval, and specific handling requirements.

- Safety Standards: Adhere to industry safety standards and regulations when selecting these racks. Ensure that the racks meet the necessary safety criteria for the storage of coils.

By taking these factors into account, warehouse managers or operators can make informed decisions regarding coil rack selection and sizing, ensuring an efficient and tailored storage solution.

Coil Rack Accessories

Coil racks can be enhanced with additional features and accessories to further improve coil organization and retrieval processes. These accessories can include:

- Dividers: Dividers can be used to separate coils within a rack, preventing them from touching and reducing the risk of damage. Dividers can also aid in organizing and categorizing coils by size, type, or any other criteria.

- Adjustable Arms: Some coil racks feature arms that can be adjusted or repositioned to accommodate coils of varying sizes. This flexibility enables more efficient use of rack space and increased versatility.

- Safety Nets or Straps: Safety nets or straps can be attached to these racks to provide an additional layer of protection, preventing coils from shifting or falling off the rack.

- Identification Labels or Systems: Implementing a labeling or identification system can help quickly locate specific coils. This can include barcode labels, color-coding, or alphanumeric systems to facilitate efficient retrieval.

Adding these accessories to coil racks can streamline inventory management processes, improve accessibility, and enhance overall organization within the warehouse.

Coil Rack Maintenance

Regular maintenance of these racks is essential to ensure their optimal functionality. Here are some key practices to implement:

- – Inspect the racks regularly for any signs of damage or wear.

- – Repair or replace any damaged components immediately to prevent safety hazards.

- – Clean the racks periodically to remove dust, debris, or any substances that could compromise their stability.

- – Train employees on proper usage and handling techniques to minimize the risk of accidents or damage.

- – Stay updated with any manufacturer recommendations or industry guidelines regarding maintenance and safety protocols.

By following proper installation procedures and implementing regular maintenance practices, coil racks can function effectively and provide long-lasting storage solutions.

Coil Racks and Industry Standards

Ensuring compliance with industry regulations and standards is crucial when incorporating these racks into warehouse operations. Adhering to safety guidelines not only reduces the risk of accidents and injuries but also contributes to efficient and effective warehouse management.

Industry standards may include guidelines for rack design, installation, load capacity, and safety protocols. Warehouse operators should familiarize themselves with these standards and ensure that their chosen coil racks meet the required criteria. Also, regular audits and inspections can help maintain compliance and ensure ongoing safety.

Conclusion

Coil racks play a vital role in organizing and efficiently managing warehouse operations, offering a specialized solution for storing and managing coils. They provide protection, optimal space utilization, and streamlined operations. By understanding the different types of coil racks, their working principles, advantages over other storage methods, maintenance practices, and the importance of proper selection, warehouse operators can make informed decisions to enhance their storage capabilities.

Incorporating coil racks into warehouse operations not only leads to improved productivity and cost savings but also ensures the safe and proper storage of valuable assets. It is essential to choose reputable suppliers, consider real-life case studies, and comply with industry standards to maximize the benefits of coil racks and enhance overall warehouse efficiency.

Customize Your Own & Get a FREE Estimate!

Simply e-mail us at sales@plexformps.com with all your information

OR call us today & speak to one of our packaging professionals