What are automotive racks?

Automotive racks are a vital component in the transportation and storage industry. These racks are designed to maximize the movement and storage of items, providing efficiency, safety, and convenience in the supply chain.

Automotive racks are designed to give different products a dependable, uniform platform for storage and transportation. They are an essential instrument in the shipping business because of their design, which makes stacking, handling, and transporting them simple.

The importance of automotive racks

In many respects, automotive racks have transformed the manner that items are transported and stored. First off, they have made a big difference in the security and safety of products in transit. These racks’ robust design works as a barrier against impacts and vibrations, reducing the possibility of damage. Ultimately, this minimizes losses and raises customer satisfaction by guaranteeing that goods arrive at their destination in ideal shape.

Furthermore, loading and unloading procedures are now much faster and more efficient thanks to car racks. Standard dimensions and compatibility with a range of handling equipment, including pallet jacks and forklifts, allow these racks to facilitate the easy transportation and transfer of items. This reduces physical strain on employees while also saving time, which boosts output and lowers labor expenses.

Types of automotive racks

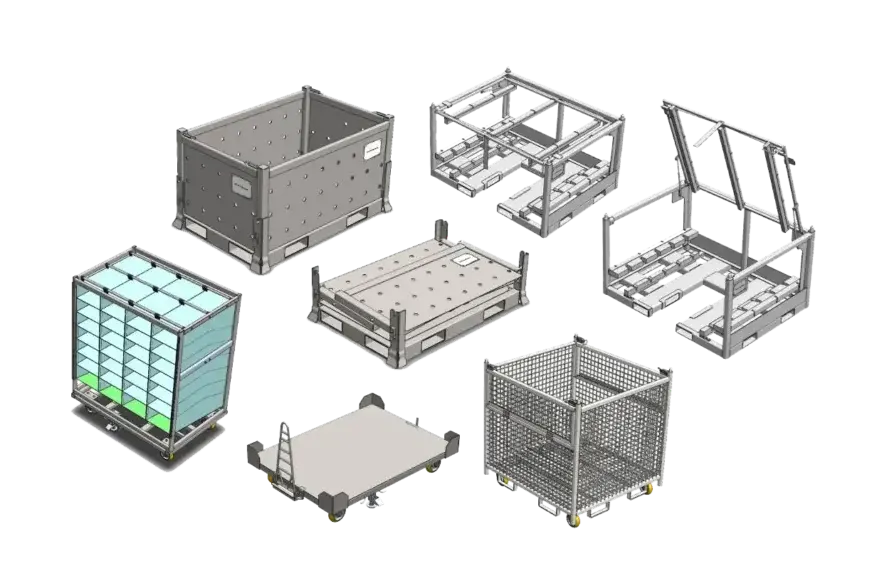

There is a wide variety of automotive racks available to suit different automotive parts and carrying needs. Here are some of the most common types:

-

Nesting Racks: The design of these racks enables them to nest inside themselves when empty. This nesting function saves space during transportation and while the racks are not in use.

-

Collapsible Racks: Due to their collapsible form, these racks are simple to fold up and store when not in use. They are very helpful for establishments with limited space because of this functionality.

-

Cantilever Racks: These racks are ideal for storing long and heavy objects. Their open storage space is created by horizontal arms that extend from vertical columns, making it simple to load and unload parts.

-

Pallet Racks: Multiple layers of storage space are created by the horizontal beams and vertical frames that support these racks. They make effective use of the vertical space, which facilitates item retrieval and access.

Factors to consider when choosing automotive racks

When choosing automotive racks, it is important to consider several factors to ensure they meet your specific needs and requirements. Here are some key factors to consider before making a purchase:

-

Weight Capacity: Consider the weight and size of the items you plan to transport. Essentially, you need to make sure the rack you choose can handle the load safely and securely.

-

Design: Take into consideration the shipment racks’ foldable and stackable designs. When not in use, collapsible racks are advantageous for convenient storage, and stackable racks enable effective use of available space.

-

Durability: Choose racks made from high-quality materials that can withstand the elements and provide long-lasting performance.

How to properly use automotive racks

Proper usage of automotive racks is essential to ensure the safety of your componenets. Here are some tips to follow when using automotive racks:

-

Load the Items Correctly: Distribute the weight evenly across the rack and make sure all items are properly secured.

-

Adhere to Weight Limits: Stay within the weight limits specified by the rack manufacturer. Essentially, overloading the rack can impact the stability and handling of your vehicle.

-

Regularly Inspect and Maintain: Periodically check the rack for any signs of wear or damage and replace any worn-out components.

Common mistakes to avoid when using automotive racks

To ensure a safe and hassle-free experience with automotive racks, it is important to avoid common mistakes. Here are some mistakes to avoid:

-

Overloading: Exceeding the weight capacity of the rack can compromise its stability and lead to accidents or damage.

-

Incorrect Installation: Improperly installing the rack can result in a loose or unstable attachment, increasing the risk of item loss or damage.

-

Neglecting Maintenance: Regular maintenance is crucial for the longevity and safety of the rack. Therefore, neglecting proper care can lead to rust, corrosion, or failure of components.

The future of automotive racks

As technology and design continue to advance, the future of automotive racks looks promising. Manufacturers are constantly improving rack systems to enhance ease of use, durability, and efficiency. Some potential developments for the future include:

-

Smart Integration: Integration of smart features to provide real-time monitoring and security for the items on the rack.

-

Lightweight Materials: Advancements in lightweight materials may lead to more lightweight rack designs.

-

Enhanced Compatibility: Manufacturers are working to develop rack systems that are more versatile and compatible with a wider range of vehicles and carrying needs.

-

Streamlined Installation: Simplified installation methods and tools to make it easier for users to install and remove racks without any hassle.

As consumer needs and preferences evolve, automotive rack technology is expected to adapt accordingly, providing more convenient and versatile solutions for transportation and storage.

Conclusion

Automotive racks are essential accessories for expanding the storage capacity of components, allowing individuals to transport a variety of items conveniently and safely. By understanding the different types of racks and considering the key factors when choosing one, you can maximize the benefits and usability of your automotive rack.

Remember to prioritize safety, comply with regulations, and keep an eye on future developments to stay up-to-date with the latest advancements in automotive rack technology.