Discover how custom metal shelving solutions can be tailored to meet your exact needs, enhancing organization and optimizing space.

Read More

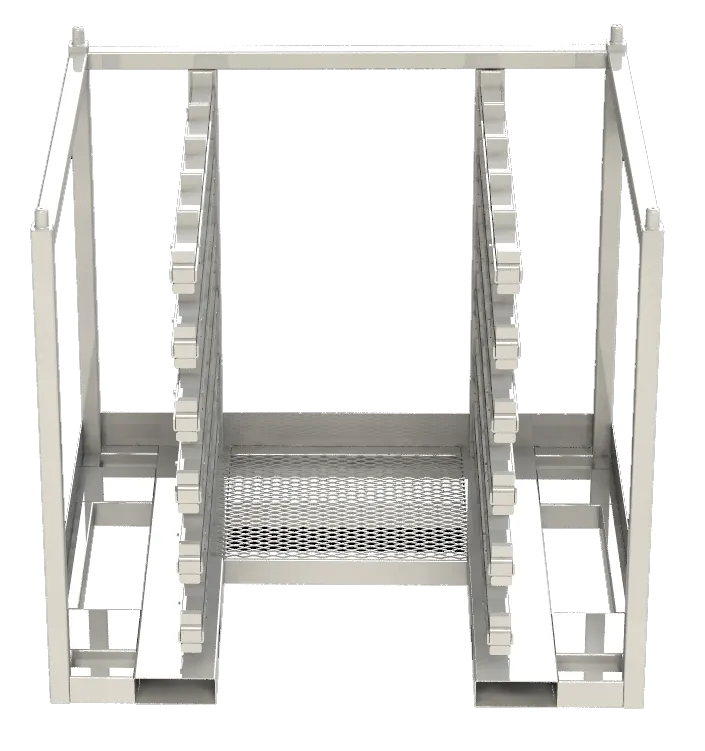

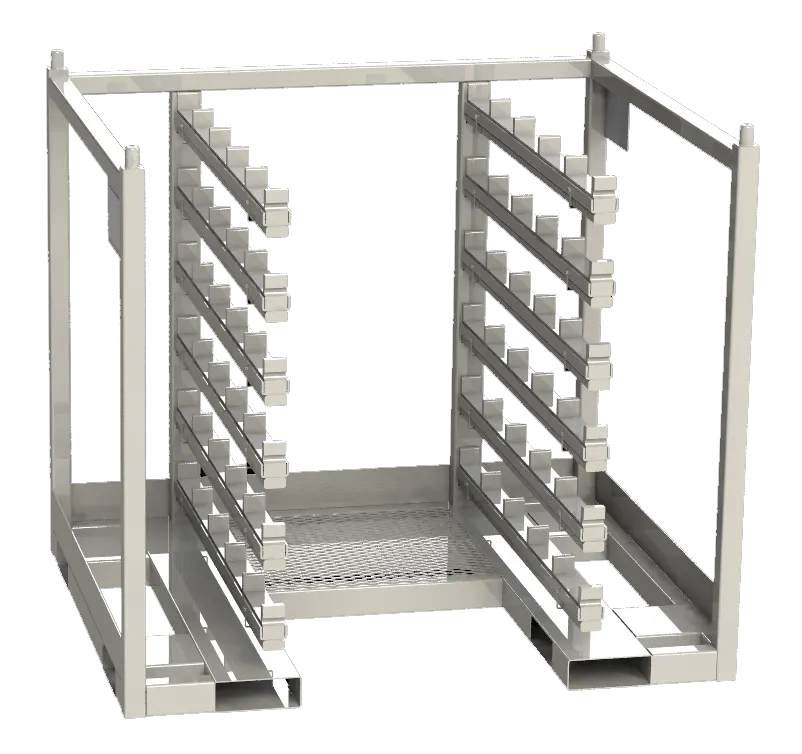

What are shipping racks for automotive parts?

Shipping racks for automotive parts play a crucial role in the transportation and storage of various components used in the automotive industry. These racks are specifically designed to securely hold and safeguard fragile and valuable parts like engines, transmissions, and body panels during shipping and handling processes.

Why are shipping racks important for automotive parts?

The significance of shipping racks in the automotive industry cannot be overstated. Here’s why these racks are important for the transportation and storage of automotive parts:

-

Maximizing Space Utilization: Shipping racks are designed to optimize storage space. By efficiently stacking parts in racks, manufacturers can maximize the utilization of warehouse space, leading to cost savings and improved workflow.

-

Protecting the Components: Automotive parts, especially delicate ones, must be protected from potential damage during shipment. Shipping racks provide a secure and stable environment, reducing risk of parts being crushed, scratched, or broken.

-

Streamlining Handling Processes: When parts are stored in racks, they are easier to handle and carry. Racks offer a consistent and controlled approach to loading and unloading, minimizing the possibility of mishandling and ensuring seamless operations.

-

Enhancing Organization: Shipping racks promote organization by allocating a specific location for each component. As a result, this makes it easier to find and use certain parts when needed, reducing time and increasing overall efficiency.

Types of shipping racks for automotive parts

There are two main types of shipping racks available for automotive parts: standard racks and customized racks.

1. Standard racks:

Standard shipment racks are pre-designed and widely accessible in the marketplace. They are frequently used for popular automotive components and come in standardized sizes and configurations. These racks are an affordable alternative for companies with simple storage and transportation requirements.

2. Customized racks:

Customized shipping racks are developed to satisfy the individual needs of an automotive manufacturer or supplier. These racks are custom-designed to fit specific part dimensions, weight capacities, and handling procedures. Consequently, customization enables companies to enhance their processes and achieve maximum efficiency.

How to choose the right shipping racks for automotive parts?

Selecting the appropriate shipping racks for automotive parts is crucial to ensure smooth operations and protect valuable components. Here are some key factors to consider when making this decision:

1. Size and dimension requirements:

The first consideration when selecting shipping racks is determining the exact size and dimensions required to accommodate the automotive parts. Racks should be able to retain the parts firmly without causing excessive movement or damage.

2. Weight capacity:

Knowing the weight capacity required is essential to prevent overloading and potential accidents. It is important to account for the weight of the parts and ensure that the racks can safely handle the load.

3. Material and durability:

Shipping racks should be composed of durable materials that can endure the stresses of shipping and storage. Steel, aluminum, and plastic are common materials used to fabricate shipping racks. Ultimately, the chosen material should be rust-resistant and long-lasting.

4. Stackability and collapsibility:

Stackability is a crucial aspect to consider because it optimizes storage space. Collapsible racks, which can be folded and stored when not in use, offer added convenience and reduce storage expenses.

5. Ease of handling and transportation:

Ensure that the shipping racks are designed for easy handling and transportation. Features such as forklift pockets, casters, and ergonomic design can greatly enhance efficiency during loading, unloading, and maneuvering.

How to optimize the use of shipping racks for automotive parts?

Once the appropriate shipping racks have been selected, there are several best practices to follow to optimize their use:

1. Proper stacking and arrangement:

To optimize space and reduce the risk of damage, it is important to properly stack the parts in the racks. Ensure that the heaviest parts are on the bottom and the smaller, more fragile components are on top. Dividers or partitions can be used to separate various parts and keep them from contacting one another.

2. Securing the parts:

Securing the parts within the racks using straps, bungee cords, or other appropriate securing methods will prevent movement and shifting during transportation. As a result, this will reduce the risk of damage caused by vibration or impact.

3. Labeling and tracking:

Implement a labeling and tracking system to easily identify and locate specific parts within the racks. Use barcode labels or RFID tags to ensure accurate inventory management and efficient retrieval.

4. Loading and unloading procedures:

Train employees on proper loading and unloading methods to reduce the possibility of accidents or damage. Clearly specify the procedures and techniques for properly handling the racks and their contents.

5. Maintenance and inspection:

Regularly inspect the shipping racks for signs of wear, breakage, or degradation. Perform routine maintenance and repairs to guarantee the racks’ lifetime and reliability. This includes replacing damaged parts, lubricating joints, and cleaning the racks.

Benefits of using shipping racks for automotive parts

The use of shipping racks in the automotive industry offers numerous benefits:

1. Efficient storage and organization:

Shipping racks optimize warehouse space by maximizing vertical storage and reducing clutter. They also promote organization by providing a designated space for each part, making it easier to locate and access specific components.

2. Protection and damage prevention:

Shipping racks safeguard automotive parts from damage during transit and handling. The racks create a secure and stable environment, reducing the likelihood of parts being crushed, bent, or broken.

3. Improved handling and transportation:

Shipping racks make handling and transit more efficient. Parts are arranged in a regular and structured manner, lowering the danger of mistreatment and assuring more efficient operations.

How to source and purchase shipping racks for automotive parts

There are several options for sourcing and purchasing shipping racks for automotive parts:

1. Directly from manufacturers:

Contact manufacturers who specialize in shipping racks for automotive parts. They can offer customized solutions based on specific requirements. This option provides direct communication with professionals and enables for customization depending on specific needs.

2. Online marketplaces and suppliers:

Utilize online marketplaces and suppliers that provide a diverse choice of shipping racks. These platforms are convenient and offer a diverse range of alternatives. To guarantee quality and reliability, it is critical to conduct extensive research on suppliers and read customer testimonials.

3. Trade shows and industry events:

Attend trade shows and industry events focused on automotive parts and logistics. These events provide an opportunity to interact with suppliers, explore new products, and learn about the latest trends and innovations in shipping rack technology.

Key considerations when implementing shipping racks for automotive parts

When implementing shipping racks for automotive parts, consider the following:

- – Conduct a thorough examination of storage and transportation requirements to determine the type and quantity of shipping racks required.

- – Train employees on proper handling, loading, and unloading procedures to ensure safety and minimize the risk of damage.

- – Regularly inspect and maintain the shipping racks to ensure their longevity and reliability.

- – Continuously review and optimize rack usage and efficiency by tracking key performance indicators and requesting staff feedback.

Conclusion

Shipping racks serve an important role in the transportation and storage of automotive parts. Automotive companies may improve efficiency, secure valuable parts, and optimize their operations by investing in the precise racks and applying best practices. Whether utilizing standard or customized racks, shipping racks provide significant benefits in terms of productivity and cost savings.