Explore innovative designs, practical applications, and the numerous benefits of utilizing a wine barrel rack for your facility.

Read More3 Brilliant Ways to Use Automotive Shipping Racks

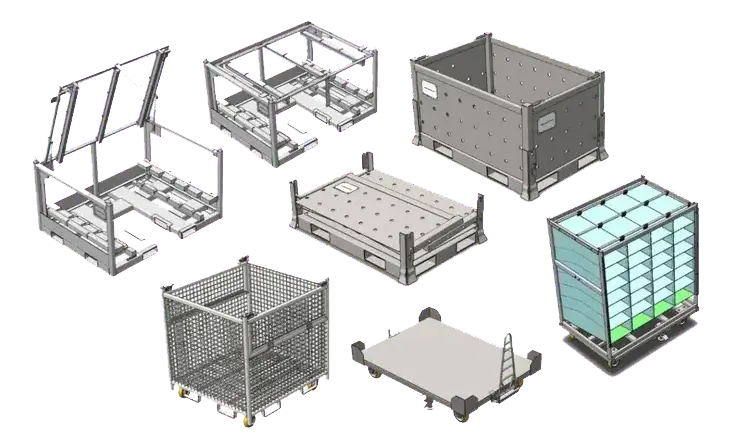

How Can You Optimize The Usage Of Automotive Shipping Racks?

Automotive part transporting is one of the most common uses for an automotive shipping rack. If you need to move your parts from point A to point B, it’s pretty much impossible without this type of equipment! Also, if you’re in the automotive industry, you know that shipping parts is a vital part of your business. It’s essential to have the right equipment and supplies at your fingertips to complete jobs quickly and efficiently. Let’s take a look at three ways that automotive shipping racks can help improve efficiency throughout your entire company:

1. Shipping Large Parts

If you have a large part that needs to be shipped, an automotive shipping rack can be a great option for you. To begin, get your forklift ready. The forklift will need to pick up the part and place it onto the rack. Once it is on the rack, use either a pallet jack or another forklift to move your steel rack through shipping channels and into its final destination. Transporting parts efficiently and effectively is one of the main key components for steel racks and companies should take full advantage of this key asset.

The automotive shipping racks will be designed to hold your part firmly and safely during transportation. All parts can have their own custom rack to accommodate it, no matter the shape and size. The style of rack and the materials utilized to hold the parts will rely on the part size and weight. Part safety is the main priority when designing and building these shipping racks as they’re useless if they cannot guarantee safety during all stages of resistance. For this reason, robust and reliable materials will be implemented in the building process for all parts.

2. Assembly Line Optimization

Automotive shipping racks are also used to optimize assembly lines. By being able to quickly and easily assemble parts at the assembly line, they allow manufacturers to increase their productivity and decrease the amount of time it takes to complete tasks. For example, operators at the assembly line can use these racks by their station to quickly load and unload parts. Consequently, parts can be assembled at a faster rate as the racks can be moved from one station to another, ultimately saving the operators time from having to walk a far distance to retrieve a part.

The overall work process for companies is sped up by utilizing automotive shipping racks. Companies are able to produce their final products ahead of schedule by eliminating time wasting activities. Without any form of holding mechanism for the parts (especially large parts) at the assembly line, this will result in the workers being forced to work inefficiently and will significantly increase labor costs.

As a bonus, companies can also reuse these racks if they needed to assemble the exact part in the future, which saves extra costs as they won’t need to reorder racks. In addition, the amount of time that will be saved in the design and development process is immense, as the customer can just reuse the previous design solution that has already worked.

3. Storage Optimization

Automotive shipping racks can be used to store parts. In this case, racks can help organize the parts and reduce the amount of space needed for storage. They’re also great for storing finished parts in the factory until they’re shipped out of the factory, or if you have a large space like a distribution center where you need to store large quantities of parts for more than one week at a time.

Storage optimization is critical for most companies as it enables companies to save warehouse storage, which ultimately leads to cost savings. The most efficient method to achieve optimal storage results is by stacking automotive shipping racks vertically. To further explain, racks typically have 4 stacking corners on the top of all corners, therefore, a forklift operator can easily pick up one rack up and safely stack it onto another.

The stacking corners are designed to be robust and they essentially lock the racks together once they are stacked. As a result, companies will save plenty of storage space as multiple racks will only accommodate a small amount of square footage. The extra space saved can be utilized for other critical functions that are necessary in the everyday working cycle for any size company.

Summary

Hopefully, you now have a better idea of how to use automotive shipping racks. They are incredibly useful pieces of equipment that can help you move heavy items in and out of your warehouse much more easily than without them. Whether you’re using these shipping racks for storage optimization, assembly line optimization, or efficient shipping, it’s always good to know about all the available advantages these racks provide!

In conclusion, we hope that you’ll consider using automotive shipping racks to help get your parts where they need to go. They’re a great way to store and transport component parts safely, and they can be used by anyone who needs them. If you want more information about our products or how we can help your company, contact us today!

Customize Your Own & Get a FREE Estimate!

Simply e-mail us at sales@plexformps.com with all your information

OR call us today & speak to one of our packaging professionals